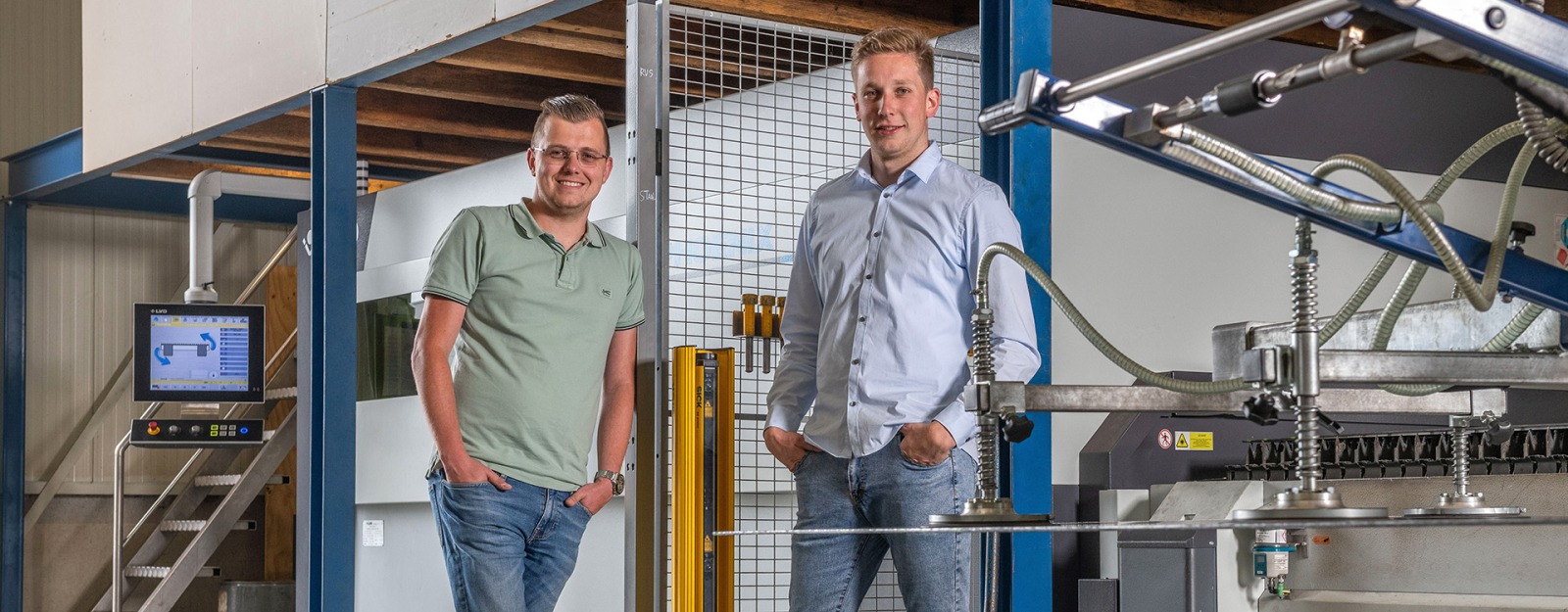

In 2008, I started my business from home. In 2013 the company moved to an industrial estate and further expanded to what it is now. Customers turn to us for piping, turning, milling and fabricating sheet metal parts. We provide semi-finished products up to complete assemblies.

We want to be more than a supplier and that's why we sit down with customers at a very early stage to provide advice on feasibility, cost-benefit ratio calculation, drawing and design and we notice there is great demand for these services. Subsequently we take care of the entire production process, completely unburdening the customer right down to final delivery.

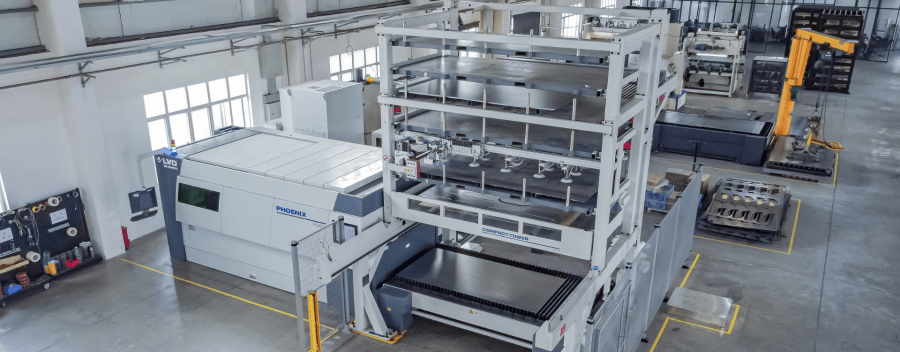

The machines are mainly used to cut steel, stainless steel and aluminium up to a thickness of 25 mm.

It was the entire buying experience that convinced us to choose LVD machines. We prepared extensively for the purchase and discussed everything in detail with LVD. We were certain we would receive the right guidance post-purchase as well. We were very confident, in fact. We selected a fibre laser cutting machine, a press brake and all the software that reduces preparatory work to a minimum. That is where our biggest profit lies.

In the past we always received PDF files whereas now we often receive STEP files. These 3D files are the easiest to import into the software. As you can see, the software automatically generates the correct unfolding, checks feasibility and gives accurate dimensions, which is the biggest advantage. We also have our own 3D file package in which we can easily modify the part.

Before we had a CO2 laser cutting machine which consumed a lot of electricity and cutting gas. We made huge strides in this area as well. I think we now consume about 25 to 30% compared to before. The cut capacity has improved by 60 to 70% on the same surface area compared to the old machine.

The software system is certainly flexible. Three people took the basic training program and now continue to learn through experience. We are now able to train a new operator within a week on the press brake or laser cutting machine so they can get started quickly.

We work on a project basis but we also often receive urgent requests that require a response within a few days. The system gives us the flexibility to quickly schedule urgent requests.

The next step is to connect CADMAN-JOB to the ERP system so we can feed prices and actual hours worked back to the ERP system to be able to not just make accurate post-calculations but also to automate this process.

The machines have improved our entire production process, we have a lower cost price and better sales rates and hardly any products are rejected. We have a firm grip on planning, meaning much higher delivery reliability.

The conclusion is that purchasing machines from LVD has reduced our costs, enabling us to remain competitive for at least the next five years.