Software

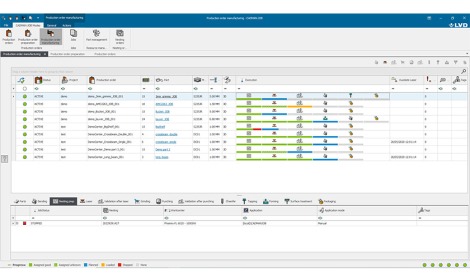

CADMAN® is LVD’s answer to full process integration. Through extensive communication with the master business systems, CADMAN helps streamline the complete process flow – from quoting, generating orders, estimated and real production times, to punching, bending, laser cutting and other operations – to realise the smart factory. CADMAN-FLOW is the single point of access to the complete software suite, seamlessly linking all CADMAN software modules.

Learn more about our complete product range

Software to streamline sheet metal fabrication

Software for sheet metal fabrication automates a number of tasks to help streamline operations, improve output, quality and efficiency. With a powerful software suite, you can optimize your entire fabrication process – from job estimate to delivery.

LVD offers the CADMAN® software package comprised of various modules at the heart of which is an intelligent central database. In combination with CADMAN software, LVD Touch controls for bending, laser cutting and punching ensure an intuitive interaction from the operator to the machine. Touch-i4, a robust industrial tablet PC, connects to the CADMAN database for an immediate, real-time view of production data.

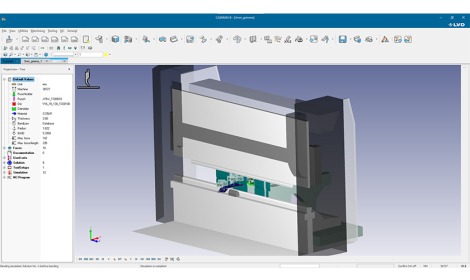

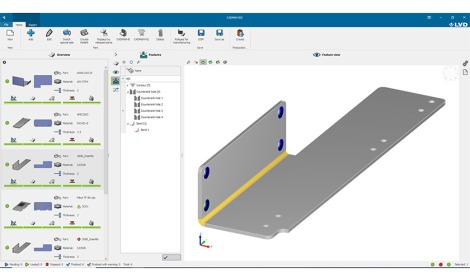

CADMAN-B is the industry’s benchmark for bend CAM software. It automatically determines the optimal bend sequence, bend program, tooling, tool and gauge positions, and generates an accurate unfolded development each and every time. It calculates bending solutions per part, per batch or fully automatically in watch mode.

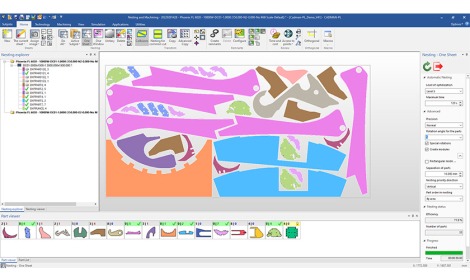

CADMAN-L for laser cutting imports 2D files, creates a nest and then connects to the real-time technology files available on the laser machine. As result, the NC program is based on the latest technologies directly useable on the machine. Automated functions include optimized sheet utilization, fly-cut, remnant creation and collision avoidance.

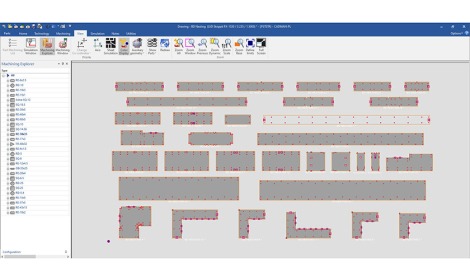

CADMAN-P optimizes programming for LVD punch presses. It features punch sequencing macros, automatic tool selection, common and non-common line punching, and complete support for complex punching and forming with optimization of tool changes.

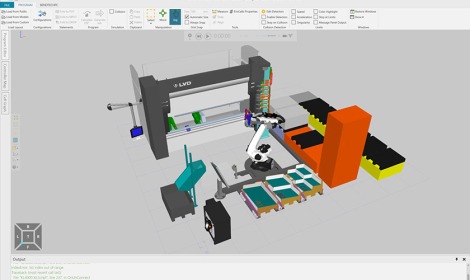

CADMAN-SIM is an intelligent programming software solution for robotic automation press brake cells. It automatically calculates a bending solution, collision-free robot path, gripper positioning and part handling in less than 10 minutes. It eliminates the need for robot teaching and facilitates “art” to “part” in under 20 minutes.

CADMAN-SDI (Smart Drawing Importer) facilitates quick import of CAD files and calculation of cost drivers. CADMAN-SDI accepts more than 40 different file formats.

CADMAN-JOB connects the CADMAN central database, ERP system, CAM and workshop for an integrated process flow. The software generates, classifies, and groups jobs in real time for all sheet metal fabrication operations.

All CADMAN products are Industry 4.0 enabled.