Press brakes

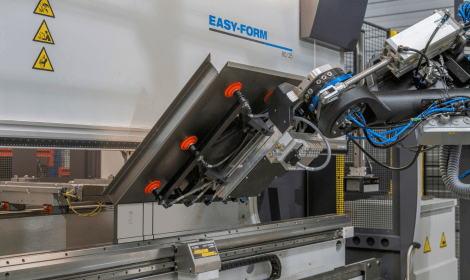

A comprehensive press brake portfolio that includes hydraulic and electric-drive machines, multi-axis press brakes with unique Easy-Form® Laser adaptive bending technology, automated bending cells, Synchro-Form for XXL applications, turnkey custom designs and LVD tooling.

Learn more about our complete product range

Sheet Metal Bending

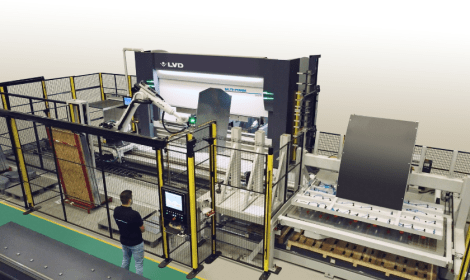

In sheet metal bending, also referred to as press braking, flanging, folding or forming, LVD puts the focus on flexible automation solutions, robot bending and process digitalisation. From cost-effective, compact electric-drive press brakes to tailor-made, multi-axis hydraulic press brakes and heavy-duty PPEB-H XXL press brakes, LVD offers the solution.

High-precision press brake automation is key in the LVD press brake range; such as the automatic tool changing press brake ToolCell and the user-friendly robotised press brakes Dyna-Cell and Ulti-Form that offer automatic programming and handle short to long runs.

When it comes to very thick or high-tensile-strength material such as Hardox®, traditional rules for determining minimum bend radius, punch radius, die openings, bending force calculations, and press brake tooling requirements may no longer apply.

LVD has developed unique technologies in order to ensure precise bending: the Easy-Form® Laser adaptive bending technology, allowing the CNC press brake to compensate for spring back, strain hardening and grain direction, and the Synchro-Form technology, used in large sheet metal bending, to automate bending of large profiles and automatically position large sheets.

The CADMAN software suite includes CADMAN-B bending software to program sheet metal bending operations offline.