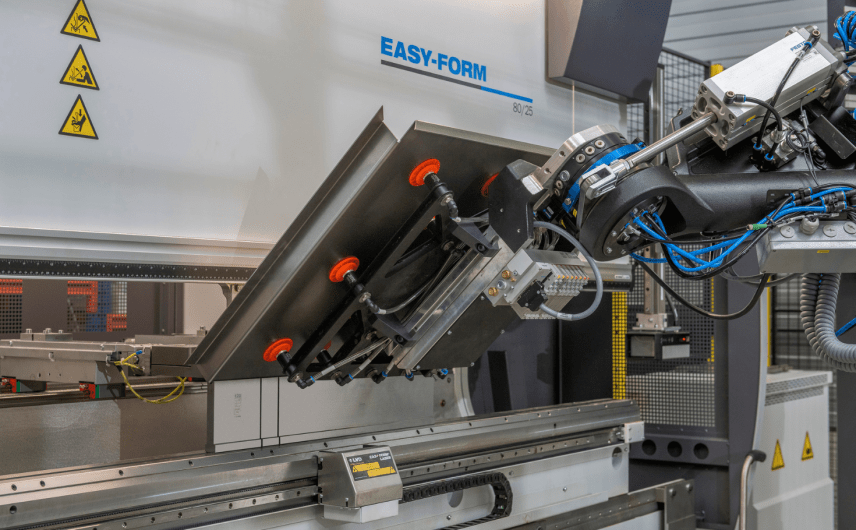

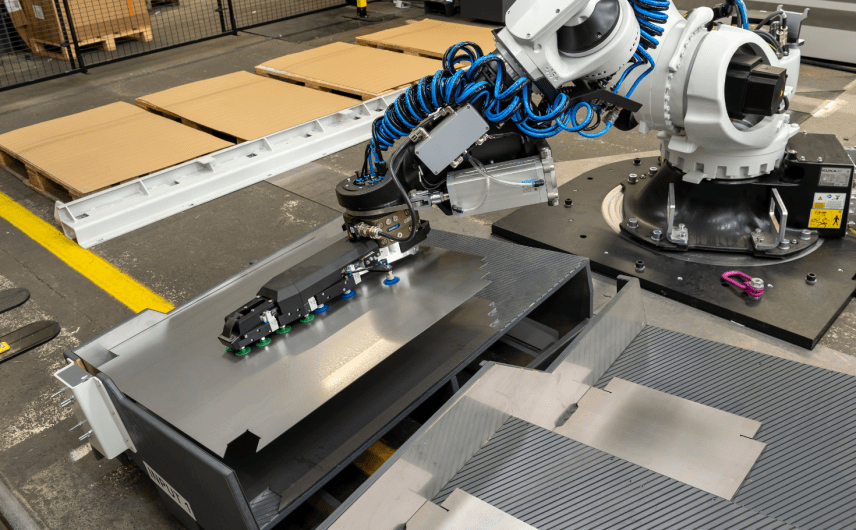

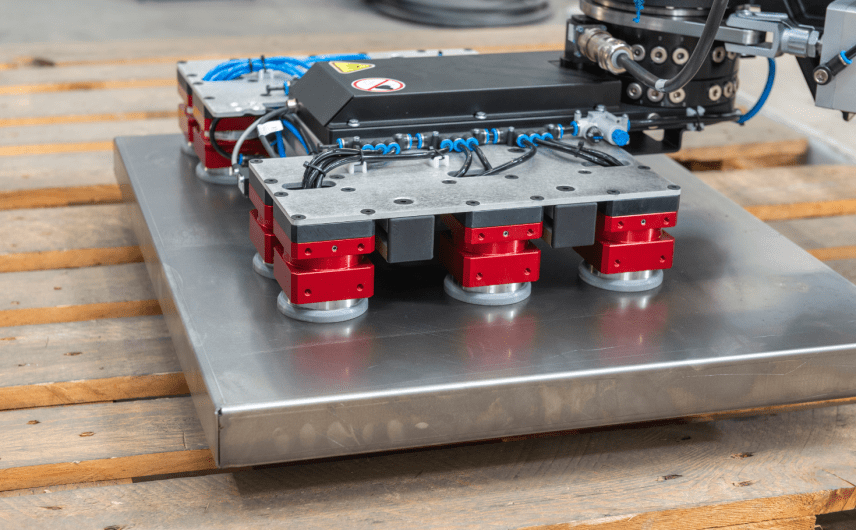

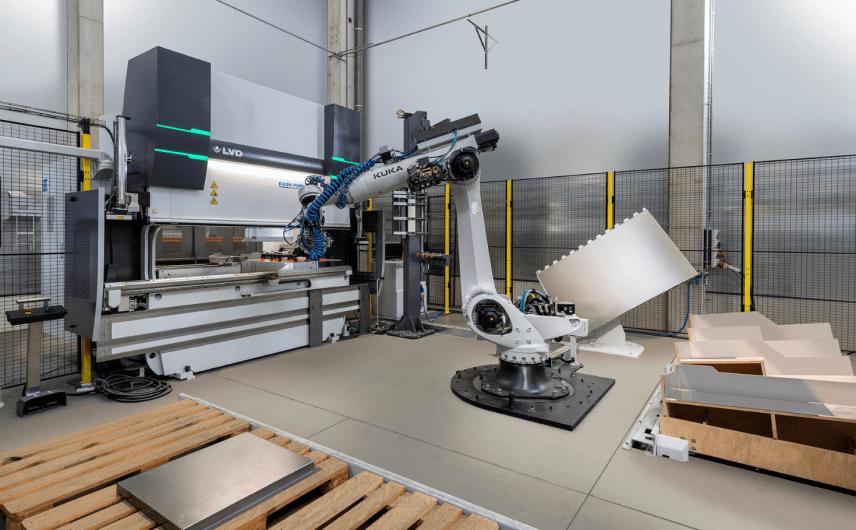

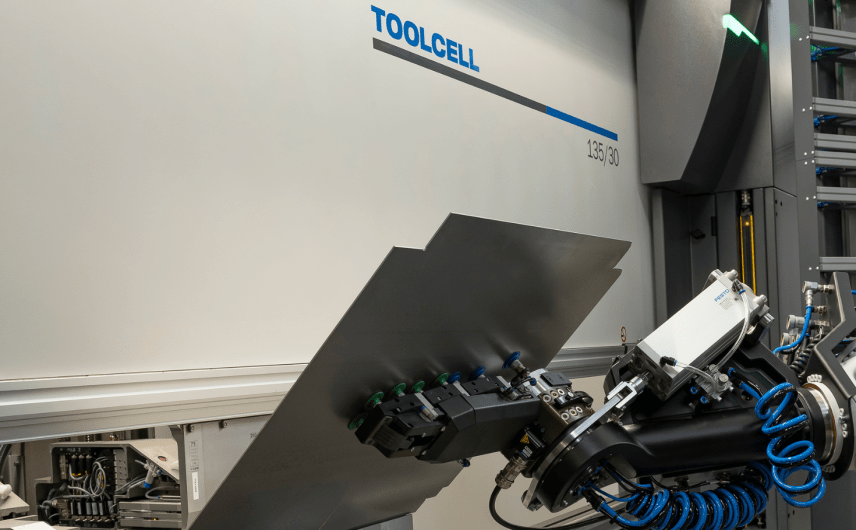

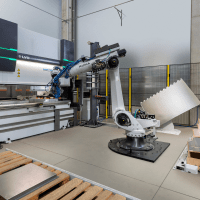

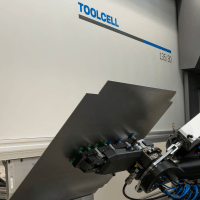

RBS 40

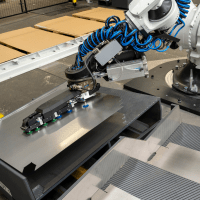

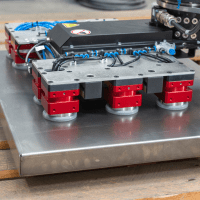

Robotic Bending System for mid-sized parts

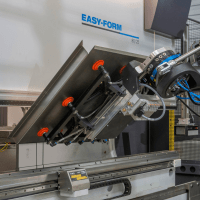

Starting from the RBS 40 platform, you can configure a fully tailored robotic bending cell with the flexibility of press brake choice, input and output options for a wide range of parts. Programming is done completely offline – with no robot teaching required.