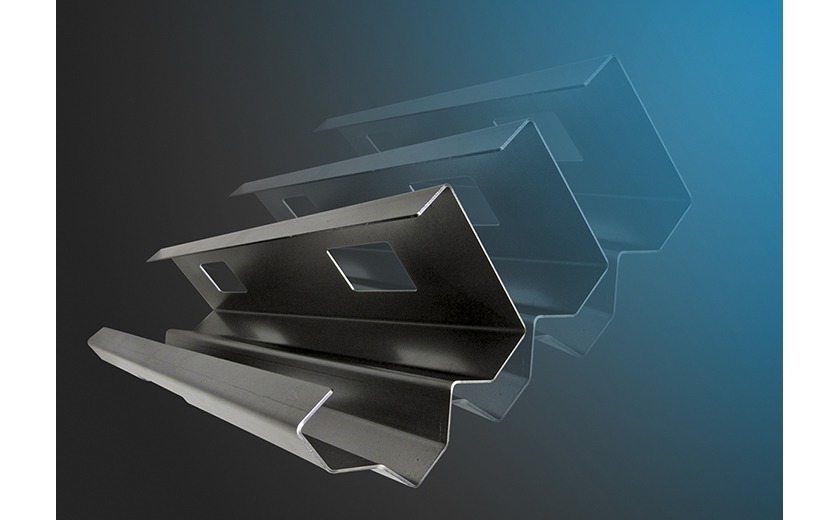

PPED

Practical and easy to use, PPED press brakes are ideal for a wide range of bending jobs. The rigid construction and servo-controlled hydraulic system offer accurate and consistent bending results. In bending capacities from 50 to 320 tons.

- 2-axis or 4-axis back gauge

- Servo-controlled hydraulic system

- Rigid frame design

- Smart factory - Industry 4.0 compatible

Highlights

Programmable X, R or X, R, Z1, Z2 backgauge

The PPED product line includes 3 models (PPED-4, PPED-5 and PPED-7) featuring either a 2- or 4-axis backgauge as standard for greater flexibility and reduced set-up time.

CNC crowning

The crowning system overcomes machine deflection to assure an accurate, repeatable bend. Standard on PPED-5 and PPED-7 models (not on 50 & 80 ton models).

Rigid frame design

All PPED models are designed and built utilising a welded one-piece frame machined without repositioning and stress relieved to guarantee machine precision.

Servo-controlled hydraulics

The hydraulic components are machined in-house to a high standard from a solid steel billet. The hardened steel pistons are precisely finished and micropolished for a lifetime of trouble-free service.

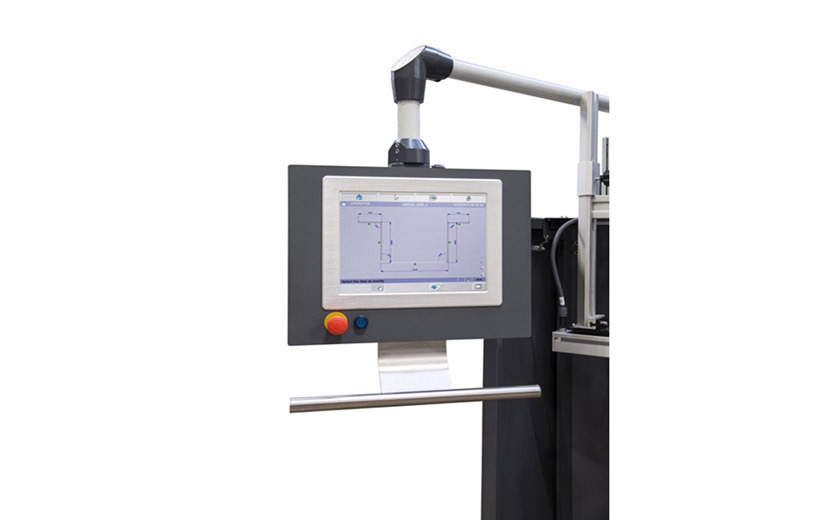

Touch-B control

LVD’s touch screen control is simple to operate with a graphical, icon-driven user interface. It provides synchronised control of the machine allowing positioning of all available axes.

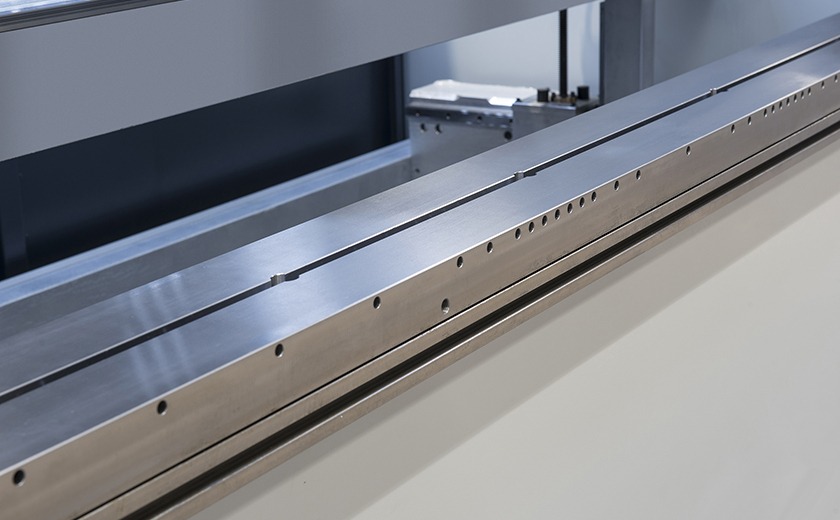

Linear encoders

High-precision linear encoders provide high positioning accuracy and repeatability.

CADMAN® software suite

A full suite of software modules create a fully integrated process flow, including CADMAN-B bend programming software, CADMAN-SDI drawing importer, CADMAN-JOB real-time data collection, job tracking and ERP connection, as well as a Touch-i4 tablet for KPI performance indication and sorting and validating parts.

Technical data

| Type | 50/20 | 80/25 | 135/30 | 165/30 | 165/40 | |

| Pressing force | kN | 500 | 800 | 1350 | 1650 | 1650 |

| Working length | mm | 2000 | 2500 | 3050 | 3050 | 4000 |

| Distance between uprights | mm | 1550 | 2050 | 2600 | 2600 | 3150 |

| Stroke | mm | 200 | 200 | 200 | 200 | 200 |

| Distance table/ram | mm | 500 | 500 | 500 | 500 | 500 |

| Gap | mm | 200 | 200 | 250 | 250 | 250 |

| Table width | mm | 140 | 140 | 180 | 180 | 180 |

| Maximum load table | kN/m | 1000 | 1000 | 1000 | 1000 | 1000 |

| Working height | mm | 930 | 930 | 970 | 970 | 970 |

| Approach speed* | mm/s | 160 | 130 | 90 | 110 | 110 |

| Working speed** | mm/s | 9 | 10 | 10 | 10 | 10 |

| Return speed | mm/s | 95 | 100 | 95 | 100 | 100 |

| Motor | kW | 4 | 7.5 | 15 | 18 | 18 |

| Oil | L | 125 | 200 | 275 | 300 | 300 |

*In CE-countries the machine is as standard equipped with a safety system.

**Limited to the safety norm for CE-countries.

Specifications subject to change without prior notice.

| Type | 200/30 | 200/40 | 260/30 | 260/40 | 320/30 | 320/40 | |

| Pressing worce | kN | 2000 | 2000 | 2600 | 2600 | 3200 | 3200 |

| Working length | mm | 3050 | 4000 | 3050 | 4000 | 3050 | 4000 |

| Distance between uprights | mm | 2600 | 3150 | 2600 | 3150 | 2600 | 3150 |

| Stroke | mm | 200 | 200 | 300 | 300 | 300 | 300 |

| Distance table/ram | mm | 500 | 500 | 670 | 670 | 670 | 670 |

| Gap | mm | 300 | 300 | 300 | 300 | 300 | 300 |

| Table width | mm | 180 | 180 | 250 | 250 | 250 | 250 |

| Maximum load table | kN/m | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| Working height | mm | 970 | 970 | 1000 | 1000 | 1000 | 1000 |

| Approach speed* | mm/s | 100 | 100 | 90 | 90 | 75 | 75 |

| Working speed** | mm/s | 9 | 9 | 10 | 10 | 8 | 8 |

| Return speed | mm/s | 90 | 90 | 80 | 80 | 75 | 75 |

| Motor | kW | 18 | 18 | 22 | 22 | 22 | 22 |

| Oil | L | 350 | 350 | 400 | 400 | 400 | 400 |

Options

Front supports

Front supports allow quick positioning along the entire bending line.