Ricobb

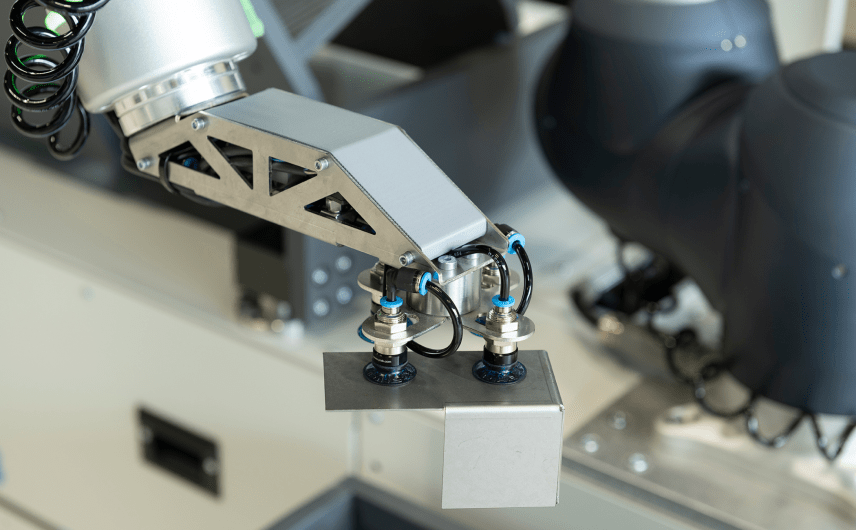

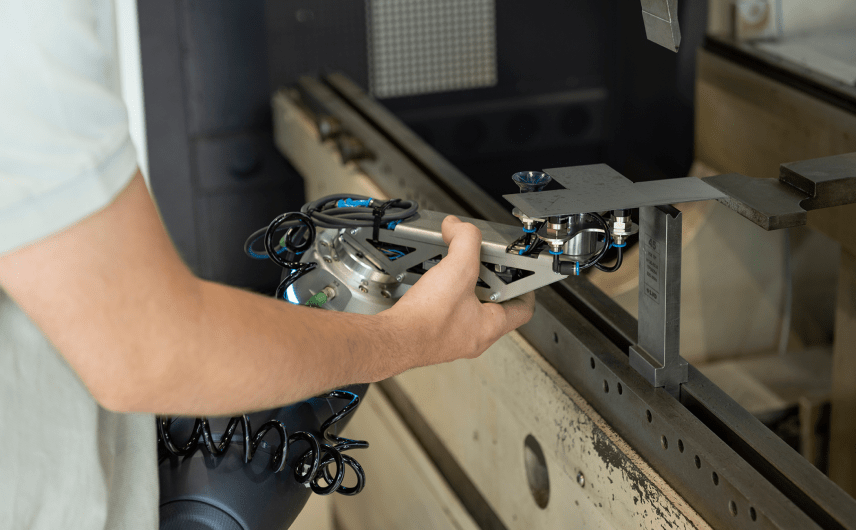

Cost-effective cobot bending

Ricobb is a flexible, collaborative bending system that cost-effectively bends small parts up to 4 kg. The system integrates seamlessly with LVD press brakes from 2001 onwards, boosting productivity, reducing labour shortages, and adapting easily to shifting production demands.

- Cost-effective automation

- Compatible with LVD press brakes since 2001

- Fast integration and easy programming

- Customisable grippers