Automation

MOVit automation systems increase the productivity of LVD laser cutting and punching machines and range from basic load/unload systems to full material storage, retrieval and warehouse.

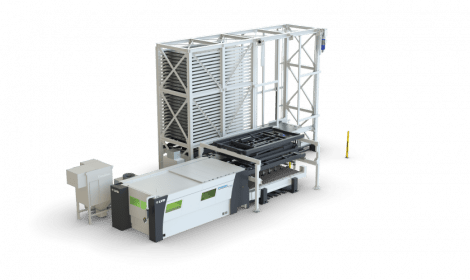

Laser automation

From increased efficiency and precision to improved safety, automated cutting machines help businesses stay competitive. There are different types of laser automation. Automated flatbed lasers feature load/unload or warehouse automation systems to significantly increase productivity by reducing downtime between jobs. Bundle feeders are a valuable component of tube lasers, improving accuracy and workplace safety.

Flexible automation systems streamline operations and reduce the need for manual labour, freeing up workers to focus on higher-value tasks, reducing errors and also the risk of injuries. This means that automation laser can lead to a safer work environment and lower insurance costs.

Automatic tube cutting machines feature a bundle feeder, that feeds and positions bundles of tubes or profiles into the tube laser for processing. Bundle feeders improve accuracy, reduce the risk of errors associated with manual handling of tubes and profiles and improve workplace safety.

Additionally, laser automation enables manufacturers to collect data to optimise their production process, and ultimately product quality and profitability.