PPEB

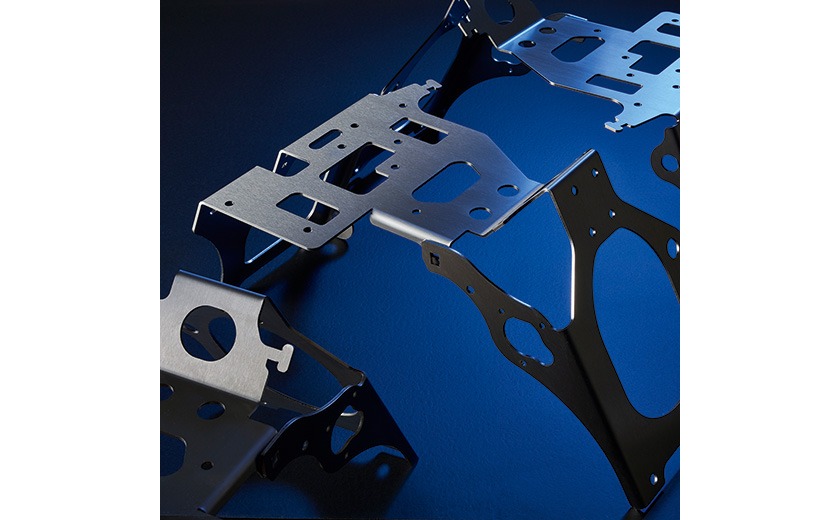

High precision and high flexibility. The PPEB press brake is a robust, technology-rich machine. PPEB gives you the freedom to configure a press brake to your production needs. In bending capacities from 80 to 640 tons.

- 2-, 5-, or 6-axis backgauge

- Turbo hydraulics for high-speed bending

- Numerous configuration choices

- Smart factory - Industry 4.0 compatible

Highlights

Tailor-made

Numerous options ensure that your PPEB completely matches your application requirements: increased distance table-ram, wider table, hydraulic clamping, and many more.

Flexible backgauge system

The 2-, 5- or 6-axis backgauge, from X-R to X-R-Z1-Z2-X’, is automatically positioned for optimum bending results.

Automatic crowning

The crowning system overcomes machine deflection to assure an accurate, repeatable bend. Our wedge system is custom-made for each machine. It accounts for crowning across the full length of the bed because it’s machined specifically for it. Standard on PPEB-5 and PPEB-8.

Robust frame

A one-piece welded frame ensures machine precision. For PPEB machines up to 400 ton/4m the frame can be installed at floor level.

Accurate hydraulic system

The servo-hydraulic system ensures that the piston at each end of the ram reaches the programmed position established in the Touch-B control. This assures a correct bend angle under the piston.

Hydraulic components

Hydraulic cylinders are machined from a solid steel billet. Pistons are steel forgings, hardened, precision-ground and mirror polished for year of trouble-free service.

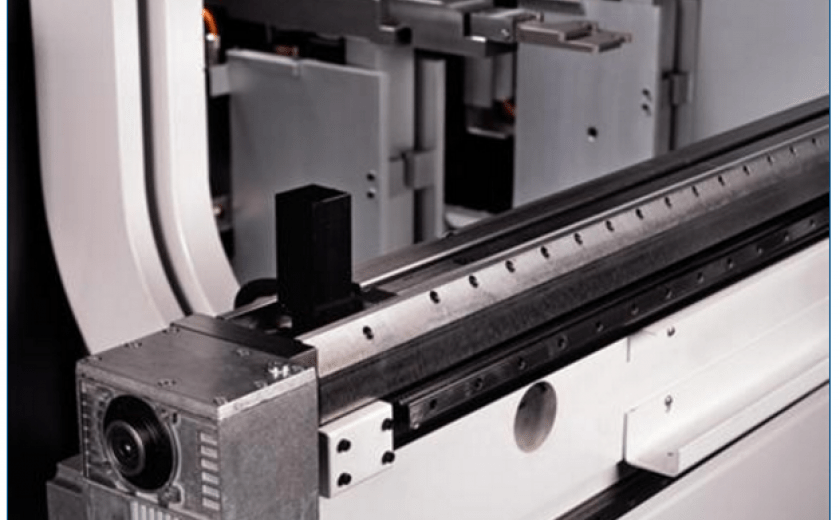

Linear encoders

Linear encoders are connected to the machine in a manner that prevents deformation during bending to influence the positioning accuracy of the ram.

Touch-B control

The 19” Touch-B control is easy to understand and simple to use. Its easy operation helps reduce the “art to part” production time.

CADMAN® software suite

A full suite of software modules create a fully integrated process flow, including CADMAN-B bend programming software, CADMAN-SDI drawing importer, CADMAN-JOB real-time data collection, job tracking and ERP connection, as well as a Touch-i4 tablet for KPI performance indication and sorting and validating parts.

Technical data

| Type | 50/20 | 80/15 | 80/20 | 80/25 | 80/Turbo | 110/30 | 110/40 | 110/42 | 110/Turbo | 135/30 | 135/40 | ||

| Pressing force | kN | 500 | 800 | 800 | 800 | 800 | 1100 | 1100 | 1100 | 1100 | 1350 | 1350 | |

| Pressure | bar | 290 | 290 | 290 | 290 | 290 | 245 | 245 | 245 | 245 | 290 | 290 | |

| Working length | mm | 2000 | 1500 | 2000 | 2500 | - | 3050 | 4000 | 470 | - | 3050 | 4000 | |

| Distance between uprights | mm | 1550 | 1050 | 1550 | 2050 | - | 2600 | 3150 | 3820 | - | 2600 | 3150 | |

| Stroke | mm | 200 | 200 | 200 | 200 | - | 200 | 200 | 200 | - | 200 | 200 | |

| Distance table/ram | mm | 400 | 400 | 400 | 400 | - | 400 | 400 | 400 | - | 400 | 400 | |

| Gap | mm | 300 | 400 | 400 | 400 | - | 400 | 400 | 400 | - | 400 | 400 | |

| Table width | mm | 120 | 120 | 120 | 120 | - | 120 | 120 | 120 | - | 120 | 120 | |

| Maximum load table | kN/m | 2000 | 2000 | 2000 | 2000 | - | 2000 | 2000 | 2000 | - | 2000 | 2000 | |

| Working height | mm | 970 | 970 | 970 | 970 | - | 970 | 970 | 970 | - | 970 | 970 | |

| Approach speed* | mm/s | 150 | 130 | 130 | 130 | 160 | 130 | 130 | 130 | 180 | 130 | 130 | |

| Working speed** | mm/s | 17 | 13 | 13 | 13 | 22 | 12 | 12 | 12 | 22 | 15 | 15 | |

| Return speed | mm/s | 190 | 140 | 140 | 200 | 115 | 115 | 115 | 115 | 200 | 115 | 115 | |

| Motor | kW | 7,5 | 11 | 11 | 11 | 15 | 15 | 15 | 15 | 22 | 15 | 15 | |

| Weight | kg | 5500 | 5500 | 6000 | 6500 | - | 9500 | 11,000 | 12,000 | - | 9500 | 11,000 | |

| Oil Tank | L | 180 | 125 | 125 | 125 | 125 | 250 | 250 | 250 | - | 250 | 250 |

*For CE-countries only if the machine is equipped with an optional safety system.

**For CE-countries working speed is limited to safety norms.

Different combinations of stroke and daylight are available in our standard range by steps of +100 mm

Specifications subject to change without prior notice.

| Type | 135/42 | 135/turbo | 170/30 | 170/40 | 170/42 | 170/51 | 170/turbo | 220/30 | 220/30 Plus | 220/40 | 220/40 Plus | ||

| Pressing force | kN | 1350 | 1350 | 1700 | 1700 | 1700 | 1700 | 1700 | 2200 | 2200 | 2200 | 2200 | |

| Pressure | bar | 290 | 290 | 285 | 285 | 285 | 285 | 285 | 285 | 285 | 285 | 285 | |

| Working length | mm | 4270 | - | 3050 | 4000 | 4270 | 5100 | - | 3050 | 3050 | 4000 | 4000 | |

| Distance between uprights | mm | 3820 | - | 2600 | 3150 | 3820 | 4550 | - | 2600 | 2600 | 3150 | 3150 | |

| Stroke | mm | 200 | - | 200 | 200 | 200 | 200 | - | 200 | 300 | 200 | 300 | |

| Distance table/ram | mm | 400 | - | 400 | 400 | 400 | 400 | - | 400 | 570 | 400 | 570 | |

| Gap | mm | 400 | - | 400 | 400 | 400 | 400 | - | 400 | 400 | 400 | 400 | |

| Table width | mm | 120 | - | 120 | 120 | 120 | 120 | - | 120 | 200 | 120 | 200 | |

| Maximum load table | kN/m | 2000 | - | 2000 | 2000 | 2000 | 2000 | - | 2000 | 2500 | 2000 | 2500 | |

| Working height | mm | 970 | - | 970 | 970 | 970 | 1020 | - | 970 | 1000 | 970 | 1000 | |

| Approach speed | mm/s | 130 | 180 | 130 | 130 | 130 | 130 | 180 | 120 | 120 | 120 | 120 | |

| Working speed | mm/s | 12 | 22 | 15 | 15 | 15 | 15 | 22 | 21 | 21 | 21 | 21 | |

| Return speed | mm/s | 115 | 200 | 160 | 160 | 160 | 160 | 200 | 200 | 200 | 200 | 200 | |

| Motor | kW | 15 | 22 | 22 | 22 | 22 | 22 | 37 | 37 | 37 | 37 | 37 | |

| Weight | kg | 12,000 | - | 11,500 | 13,500 | 15,000 | 19,500 | - | 13,000 | 14,500 | 15,300 | 17,200 | |

| Oil tank | L | 250 | 250 | 350 | 350 | 350 | 350 | - | 350 | 350 | 350 | 350 |

*For CE-countries only if the machine is equipped with an optional safety system.

**For CE-countries working speed is limited to safety norms.

Different combinations of stroke and daylight are available in our standard range by steps of +100 mm

Specifications subject to change without prior notice.

| Type | 220/42 | 220/42 Plus | 220/51 | 220/51 Plus | 220/61 | 220/61 Plus | 320/30 | 320/40 | 320/45 | 320/51 | 320/61 | ||

| Pressing force | kN | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 3200 | 3200 | 3200 | 3200 | 3200 | |

| Pressure | bar | 285 | 285 | 285 | 285 | 285 | 285 | 285 | 285 | 285 | 285 | 285 | |

| Working length | mm | 4270 | 4270 | 5100 | 5100 | 6100 | 6100 | 3050 | 4000 | 4500 | 5100 | 6100 | |

| Distance between uprights | mm | 3820 | 3820 | 4550 | 4550 | 5050 | 5050 | 2600 | 3150 | 3820 | 4270 | 5050 | |

| Stroke | mm | 200 | 300 | 200 | 300 | 200 | 300 | 300 | 300 | 300 | 300 | 300 | |

| Distance table/ram | mm | 400 | 570 | 400 | 570 | 400 | 570 | 570 | 570 | 570 | 570 | 570 | |

| Gap | mm | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| Table width | mm | 120 | 200 | 120 | 200 | 120 | 200 | 200 | 200 | 200 | 200 | 200 | |

| Maximum load table | kN/m | 2000 | 2500 | 2000 | 2500 | 2000 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | |

| Working height | mm | 970 | 1000 | 1025 | 1055 | 1025 | 1055 | 1000 | 1000 | 1000 | 1035 | 1165 | |

| Approach speed | mm/s | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | |

| Working speed | mm/s | 21 | 21 | 21 | 21 | 21 | 21 | 14 | 14 | 14 | 14 | 14 | |

| Return speed | mm/s | 200 | 200 | 200 | 200 | 200 | 200 | 130 | 130 | 130 | 130 | 130 | |

| Motor | kW | 37 | 37 | 37 | 37 | 37 | 37 | 37 | 37 | 37 | 37 | 37 | |

| Weight | kg | 17,000 | 18,700 | 21,200 | 23,400 | 24,000 | 26,400 | 21,000 | 23,000 | 25,500 | 29,000 | 36,000 | |

| Oil tank | L | 350 | 350 | 350 | 350 | 350 | 350 | 400 | 400 | 400 | 400 | 400 |

*For CE-countries only if the machine is equipped with an optional safety system.

**For CE-countries working speed is limited to safety norms.

Different combinations of stroke and daylight are available in our standard range by steps of +100 mm

Specifications subject to change without prior notice.

| Type | 400/40 | 400/45 | 400/51 | 400/61 | 500/40 | 500/45 | 500/51 | 500/61 | 640/45 | 640/61 | 640/81 | ||

| Pressing force | kN | 4000 | 4000 | 4000 | 4000 | 5000 | 5000 | 5000 | 6400 | 6400 | 6400 | 6400 | |

| Pressure | bar | 290 | 290 | 290 | 290 | 290 | 290 | 290 | 290 | 290 | 290 | 290 | |

| Working length | mm | 4000 | 4500 | 5100 | 6100 | 4000 | 4500 | 5100 | 6100 | 4500 | 6100 | 8100 | |

| Distance between uprights | mm | 3150 | 3820 | 4270 | 5050 | 3150 | 3760 | 4050 | 5050 | 3760 | 5050 | 7050 | |

| Stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | |

| Distance table/ram | mm | 570 | 570 | 570 | 570 | 570 | 570 | 570 | 570 | 570 | 570 | 570 | |

| Gap | mm | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| Table width | mm | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

| Maximum load table | kN/m | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | |

| Working height | mm | 970 | 970 | 970 | 970 | 970 | 970 | 970 | 970 | 970 | 970 | 970 | |

| Approach speed | mm/s | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 90 | 90 | 90 | |

| Working speed | mm/s | 11 | 11 | 11 | 11 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | |

| Return speed | mm/s | 120 | 120 | 120 | 120 | 80 | 80 | 80 | 80 | 100 | 100 | 100 | |

| Motor | kW | 37 | 37 | 37 | 37 | 37 | 37 | 37 | 37 | 55 | 55 | 55 | |

| Weight | kg | 30,500 | 32,000 | 34,000 | 37,000 | 39,400 | 42,200 | 43,820 | 49,420 | 49,300 | 57,000 | 71,550 | |

| Oil tank | L | 500 | 500 | 500 | 500 | 650 | 650 | 650 | 650 | 850 | 850 | 850 |

*For CE-countries only if the machine is equipped with an optional safety system.

**For CE-countries working speed is limited to safety norms.

Different combinations of stroke and daylight are available in our standard range by steps of +100 mm

Specifications subject to change without prior notice.

Options

Hydraulic clamping

Quick-acting hydraulic clamping on the ram and on the table allow faster setups and greater production efficiency.

Front supports

Front supports on guide rails allow quick positioning along the entire bending line.

Additional gauging finger

Sheet followers

Two programmable sheet followers reinforce the sheet during bending. They make full contact with the plate, preventing sheet sagging.

Increased stroke/table-ram distance

Increase table-ram distance, stroke of the ram and increased gap in 100 mm steps for elevated input.

Hemming table

Install a hemming table when you frequently need to create soft or rounded safety edges or add strength to finished parts.

Laser Safe guarding system

The IRIS transmitter and receiver features an imaging system capable of tracing the bending line in correspondence with the tools, allowing you to work with speed changes less than 1mm from the sheet metal.

Turbo press drive

A turbo-driven press drive provides high-speed bending and increased energy efficiency over conventional hydraulics.

Robot interface

Add a robot interface connection to integrate any model of industrial robot now or in the future.