“I casually walked by reception, and when I saw a particular detail on the brochure, I chased them out to the parking lot to have them come in and tell me more about it.”

The feature that piqued Del Giacco’s interest? The Taurus laser cutting machine’s open bed. “If you have an 80-foot-long enclosed machine, it actually becomes 160 feet long—and that’s a huge amount of space wasted. I was very intrigued by the technology, and the quality LVD promised was high, as well. Special-length products (greater than 20 ft.) are one of our specific services. In addition, even for standardlength plates, having a longer bed can help increase efficiency,” he says.

Processing area

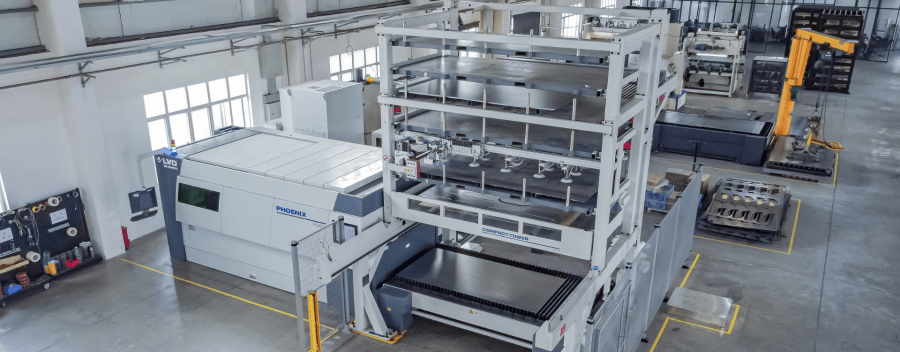

LVD’s Taurus fiber laser is engineered for extra-large cutting capacity with a modular design, allowing the machine to be expanded in increments of 13 ft. up to a maximum bed length of 137 ft. According to the company, “Taurus makes it easy to access cut parts and load raw material because only the cutting gantry is covered. The 13-ft.-wide gantry provides protection around the cutting head and nozzle changer. Taurus also features a second 19-in. controller on the gantry and a handheld control for jog actions,” as well as bevel cutting.

Del Giacco says his fiber laser is approximately 78 ft. by 12 ft., processing both stainless steel and steel plates. Stainless Structurals was cutting these parts on a CO2 laser prior to the installation of the Taurus.

“Probably the biggest advantage of the fiber compared to the CO2 laser is the speed of the cut,” he says. “It also has less kerf, which is more apparent in thicker material with a CO2 laser.” He also comments on the convenience of the bevel cutting. Instead of moving parts over to a time-consuming secondary bevel process that requires skilled labor. “If you can bevel it in the laser, most of the time, that part can be used as is. This machine can go up to 45 degrees, which is fine for most applications. In addition, it can perform a Y-shaped cut, which is very useful when welding material.”

The fiber laser’s long bed can handle multiple plates at a time, minimizing the machine’s downtime. “While we are loading on one side, it’s cutting on the other side. When it moves over, we move to the other side to unload and reload—a continuous process,” notes Del Giacco. While a short-bed machine needs to stop for unloading and loading, the Taurus can keep cutting. “That’s a huge advantage. It’s also an advantage for maintenance because personnel can maintain one area of the machine while the other is still operating.”

Big jobs, big parts

Stainless Structurals serves a variety of industries that need large parts cut, including aerospace, architecture, energy and power, oil and gas, and transportation. The company has worked on structural profiles for The James Webb Space Telescope Chamber A at NASA’s Johnson Space Center in Houston, laser-welded profiles featured on the Space Needle, and 30,000 pounds of laser-welded channels, beams and a custom cross-section for a New York City subway station.

One recent project that Del Giacco says could “only be done with a machine like the LVD Taurus” required manufacturing special shapes 600 in. long for a cooling water intake system in Albany, New York. According to a company case-study, the “large cooling water systems have to meet government regulations involving the environmental impact.”

To meet both state and federal law, the customer, Intake Screens Inc., had to design a system that would reduce both entrainment and impingement as well as provide protection to fish species. For a system submerged in water, 304/L grade stainless steel was a clear choice.

For this project, Stainless Structurals produced over 10 tons of 304/L stainless steel custom beams that were used as part of the supports and side rails for the retractable screens and slidegates. The system keeps the fish in the river, the screens free of debris and allows for screen inspection without shutting down operations.”

Service comes standard

Del Giacco says that LVD “delivered on the quality of the product.” During installation, the company provided a technician on site, as well as a library of webinars and digital content that explains the software and how to perform maintenance. “Even nowadays, they are quick to respond when we have a question,” he adds.

“It was a big surprise for me because I have had bad customer experiences with other major companies, waiting days and days for help. But, with LVD, we are having a great experience."

Company Profile

Company: Stainless Structurals LLC

Since: 2005

Industries: Aerospace; Architecture, Building & Construction; Chemical, Pharmaceutical & Petrochemical; Defense; Energy and Power; Environmetal; Food & Beverage; Manufacturing; Mining & Quarrying; Oil & Gas; Textiles, Pulp & Paper; Transportation

Works with: Stainless steel, carbon steel

LVD installations: Taurus 20 – 20 kW bevel

LVD software: CADMAN-L

Website: www.stainless-structurals.com

Images: ©2022 Intake Screens, Inc.

Reprinted with permission: Modern Metals, May 2024