Company Profile

Company: Askon Demir

Since: 2001

Industries:

mechanical engineering, transportation, energy, agriculture, mining, pipe construction for water, gas and oil, storage systems, heat exchangers, construction, decoration and furniture

Works with:

wear-resistant steel, high-strength steel, high manganese, corten, X120Mn12, commercial grades, aluminium, stainless steel, special alloys, IPE, NPI and NPU irons

LVD installations:

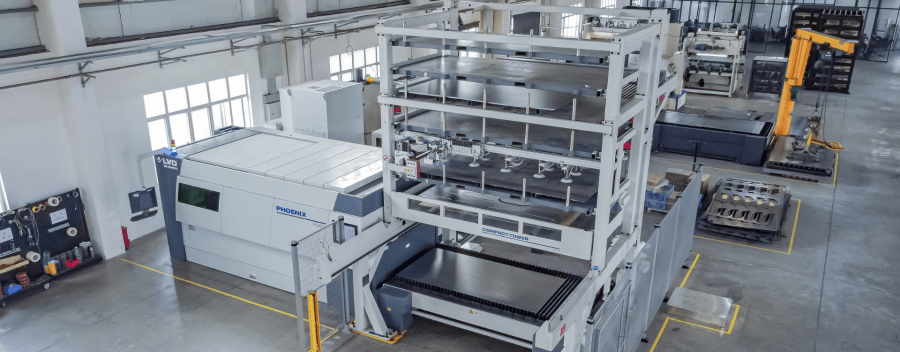

ToolCell 200/40 Plus press brake

Phoenix FL-3015 laser cutting machines: 10 and 12 kW

LVD software:

CADMAN-B, -L and -SDI

Website: www.askondemir.com