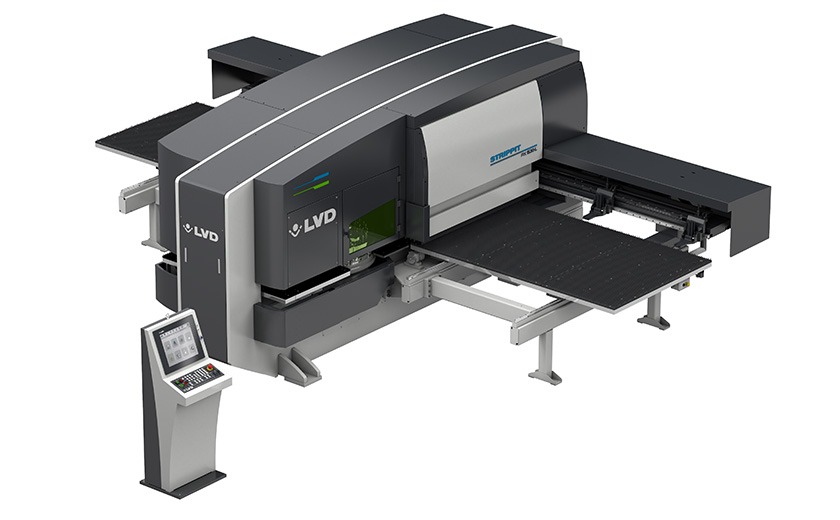

Strippit PX-L

Strippit PX-L offers the efficiency of two technologies in one machine for highly flexible manufacturing. The single-head punch press handles high-accuracy punching and forming operations. The fiber laser delivers high-quality cutting of outer contours, intricate inner contours and can be used for material etching.

- Single-head 20-ton punch press

- 4-kW laser source

- Sheet size format of 3050 x 1550 mm

- Smart factory - Industry 4.0 compatible

Highlights

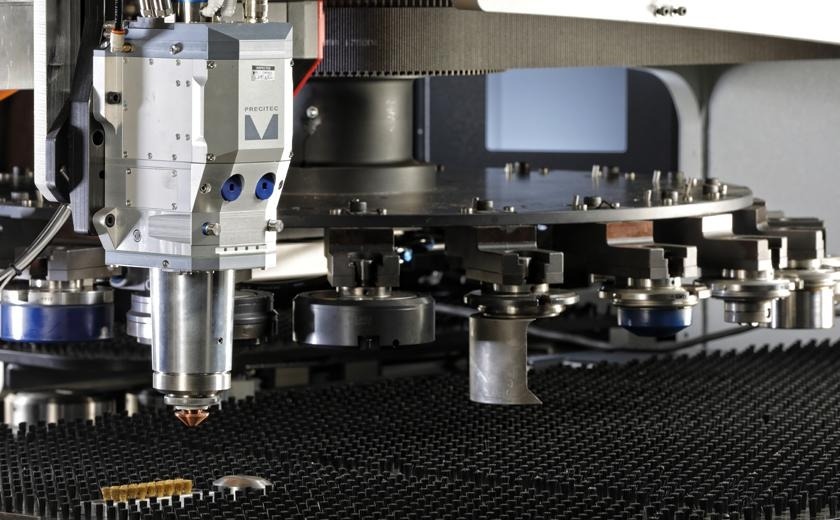

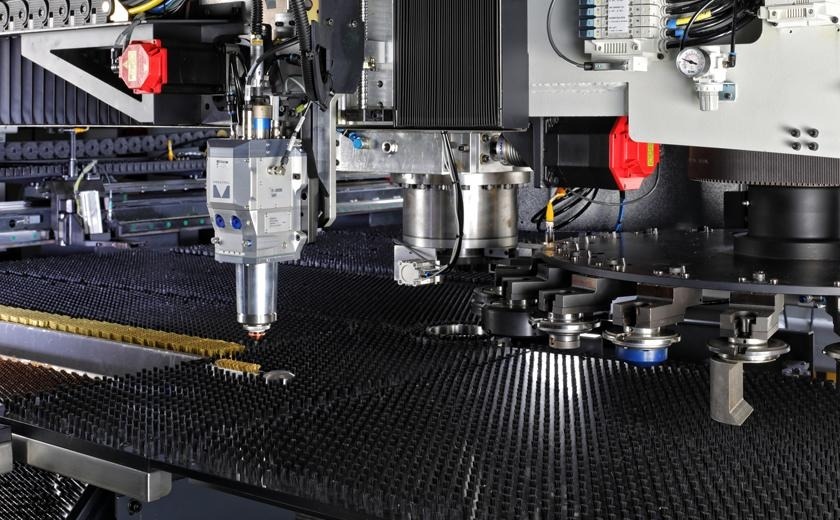

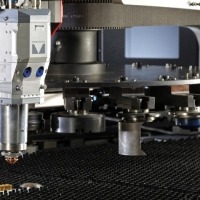

Single-head punch press

The Strippit PX single-head punch press features 20 direct-drive indexable tool stations accepting tool diameters up to 90 mm and with every tool able to rotate a full 360 degrees.

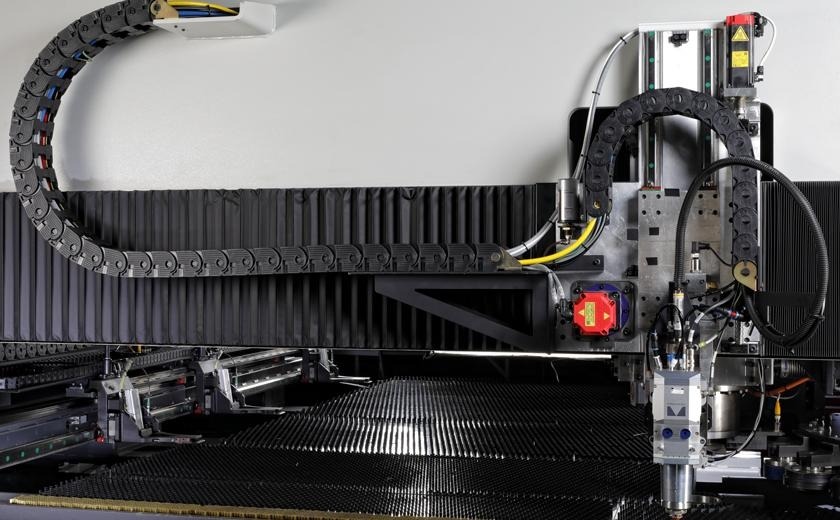

Programmable punching cycles

The Strippit PX-L has fully programmable ram cycle profiles for punching, forming and tapping to maximise machine output.

High-speed punching, forming, bending and tapping

Punch, form, bend and tap for complete part processing, including three-dimensional parts and complex geometries, using the Strippit PX-L. Forming heights up to 75 mm. Punch thicknesses up to 6.35 mm.

4-kW fiber laser

Laser cut unique shaped holes or contours and etch material with high-quality results with a 4-kW laser source.

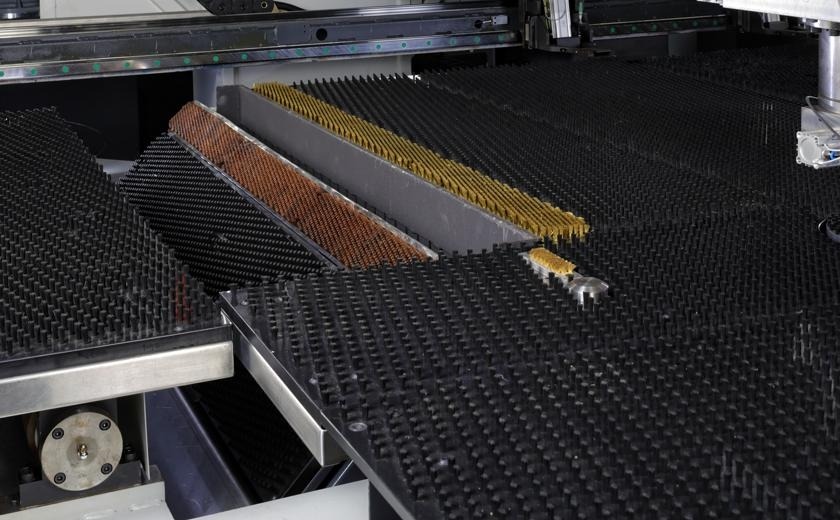

Full-sheet processing

Cut and punch a full-size workpiece of 3050 x 1525 mm without repositioning to save on production time, material usage and material handling.

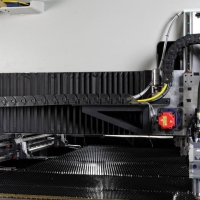

Large work chute for laser cut parts

A 406 mm x 1524 mm work chute for laser cut parts makes it easy and convenient to evacuate processed parts or scrap.

Retractable die

The retractable die ensures scratch-free punching and forming.

Intuitive Touch-PL control

The latest LVD Touch interface is intuitive to use for operators of any skill level.

CADMAN-PL programming software

Integrated with the Touch-PL controller, CADMAN-PL makes programming and job set up for punching and laser cutting virtually automatic.

Technical data

| Maximum punching capacity | 200 kN |

| Maximum material thickness | 6.35 mm |

| Punching accuracy | 0.1 mm |

| Repetitive accuracy | 0.05 mm |

| 1 mm pitch | 910 HPM |

| 25.4 mm pitch | 440 HPM |

| Marking | 1750 HPM |

| Feed clearance | 80 mm |

| Nominal worksheet size | 3050 x 1550 mm |

*material thickness + tip recess + die penetration

| Brush table* | up to 150 kg |

| Combo ball/brush | - |

| Work chute | 500 x 525 mm |

| Work clamps | 3 CNC relocatable with part pull out sensor |

*at reduced speed

| Magazine configuration | 20 stations - T-style |

| Auto-index stations | 20 stations till 90 mm |

| Wheel Tool capacity | x |

| Tapping Tool capacity | x |

| Indexable Multi-Tool capacity | x |

| Angular positioning accuracy | ± 0.05 degrees |

| Controller | Touch PL |

| Combined positioning speed X-Y | 130 m/min. |

| Tool change time | 3 - 6.5 sec. |

| Average power consumption | 14.3 kW |

| Standby operation | 0.9 kW |

| Automatic load/unload (PA) | x |

| Compact Tower (CT-P) | x |

| Flexible Automation (FA-P) | x |

| Bin sort | x |

| Robot pick/sort | x |

| Tower Automation System (TAS) | - |

| Warehouse Automation System (WAS) | - |

| Extended Tool Magazine (ETM) | - |

| Lubrication system | x |

Specifications subject to change without prior notice.

Options

Modular automation systems

An automation system further extends machine efficiency and process reliability. Choose from a range of options, including Compact Autoload, Bin-sort System, Compact Tower (CT-P) for material storage and retrieval, Flexible Automation (FA-P) for advanced loading/unloading and part picking, full Tower Automation (TAS) or Warehouse Automation (WAS). A robotic interface can also be integrated.