Leaner processes

Based in Melle, Lower Saxony, GLA-WEL is a medium-sized, family-run business that is focused on sheet metal cutting, forming and fabrication. What sets it apart from its peers is that it has its own software house, Octoflex, which has created an ERP system that is currently being used by about 100 customers.

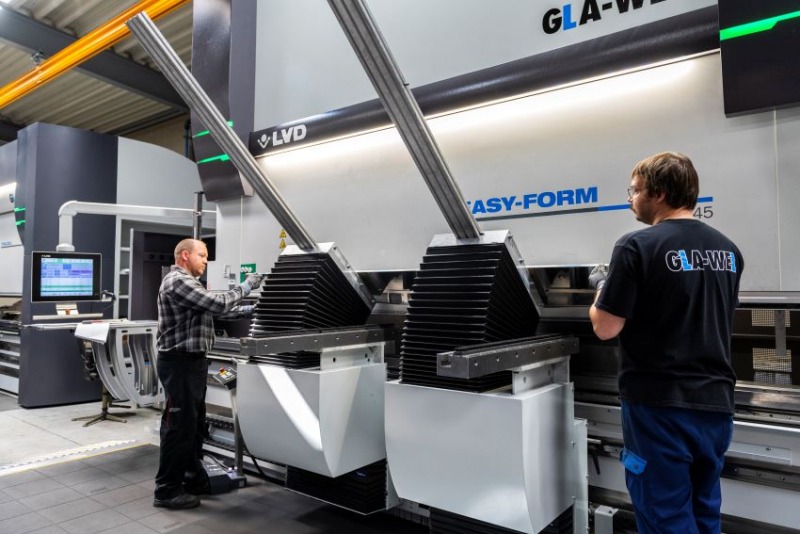

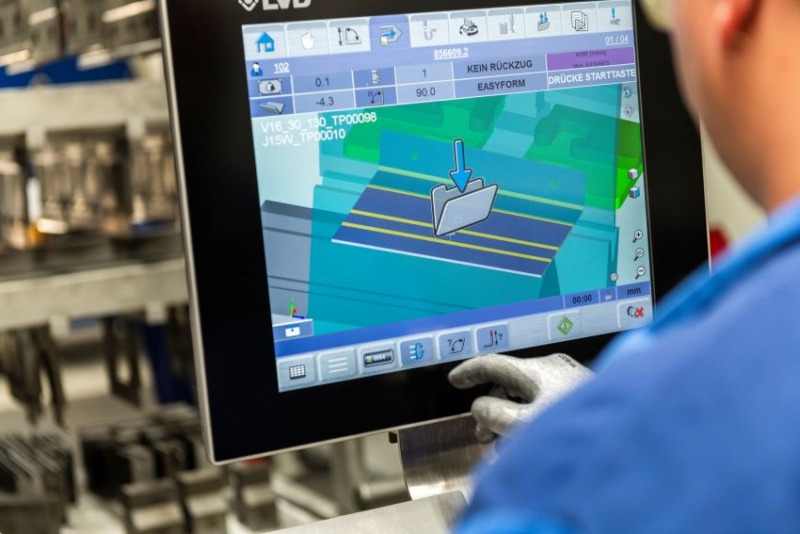

GLA-WEL runs three LVD bending systems, a 220t ToolCell with automatic tool changer and two Easy-Form press brakes, 135 and 320 tons. It is also making extensive use of LVD’s CADMAN®-SDI file importing and calculating software, CADMAN-B offline programming software and CADMAN-JOB workflow software.

Commercial Director Marcel Kemner says that, as a family business, GLA-WEL is run in a very person-to-person way, which means it can be very flexible and responsive.

“We do a lot of small series work to short timescales, so this is important. But the bigger we got, the less flexible we became. So the most important thing is to make our processes leaner so we can manufacture more quickly and efficiently.

“That is where digitalisation comes into play. Building on our Octoflex ERP system, we are creating a digital process flow so that we can automate a lot of our operations and administrative tasks.”

He says that the decision to work with LVD fundamentally came down to the ability of its software to support this.

“The LVD press brakes are superb, the technological market leaders, but what is unique is LVD’s software.”

Stephan Glahs and Simon Welkener are two of the Managing Directors of the business, who also head up Octoflex. Mr Glahs explains: “We deal with a lot of customers in the sheet metal sector and have to integrate our ERP system with different manufacturers’ software. LVD’s CADMAN software is not just a bit better than the others, it is in a league of its own. We saw that the connectivity of the LVD software could significantly improve our manufacturing capabilities. For example, it would also allow us to connect to non-LVD laser cutting machines.”