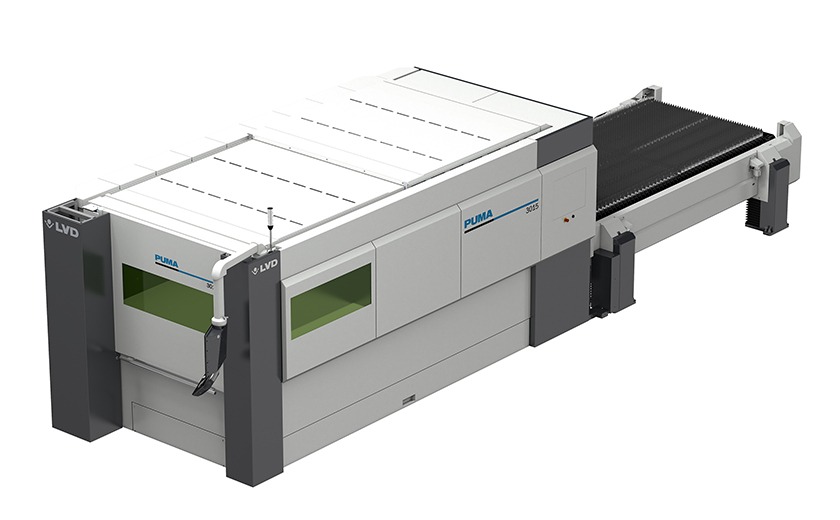

LVD introduces Puma, a new cost-efficient fiber laser cutting machine designed to provide high-technology features and performance at a lower total cost of ownership. Offered with 3-, 6- or 12-kW laser in 3050 x 1525 mm, 4065 x 2035 mm, and 6160 x 2035 formats and automation ready, Puma provides the agility to handle a diversity of cutting applications.

HIGH VALUE FOR INVESTMENT

LVD’s newest laser cutting machine addresses a growing demand for versatile laser cutting equipment built to maximize the value of a user’s investment and lower the cost per part.

Puma is designed to operate as economically as possible with high-end features that optimize cutting performance and robust construction to ensure reliable operation. The welded steel, mono-frame construction provides stability to achieve quality cutting at high feed rates.

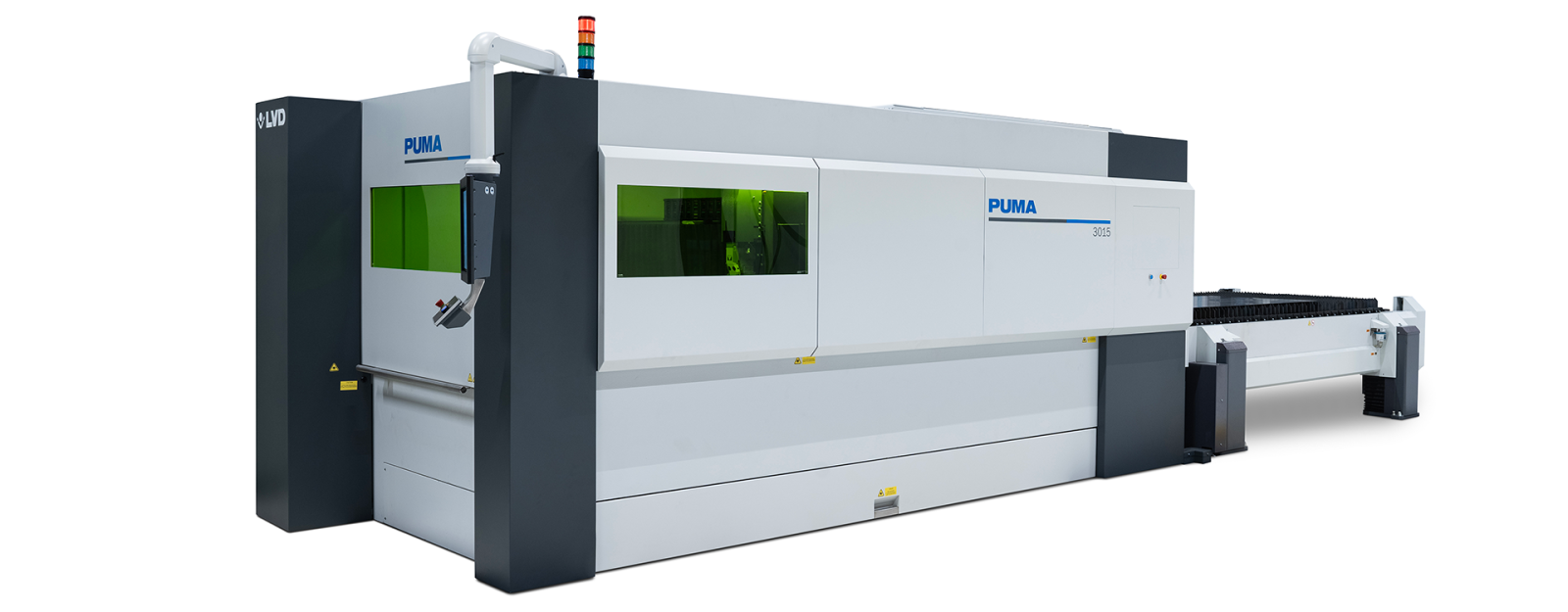

ADVANCED CUTTING HEAD, TOP DYNAMICS

The Puma cutting head uses the latest technology to deliver consistent quality and process stability. It incorporates crash protection, motorized focus position adjustment, and capacitive height sensing, as well as automated functions for sheet referencing, cutting gas selection, pressure control, and nozzle cleaning. High machine dynamics enables productive cutting across a wide range of material types and thicknesses.

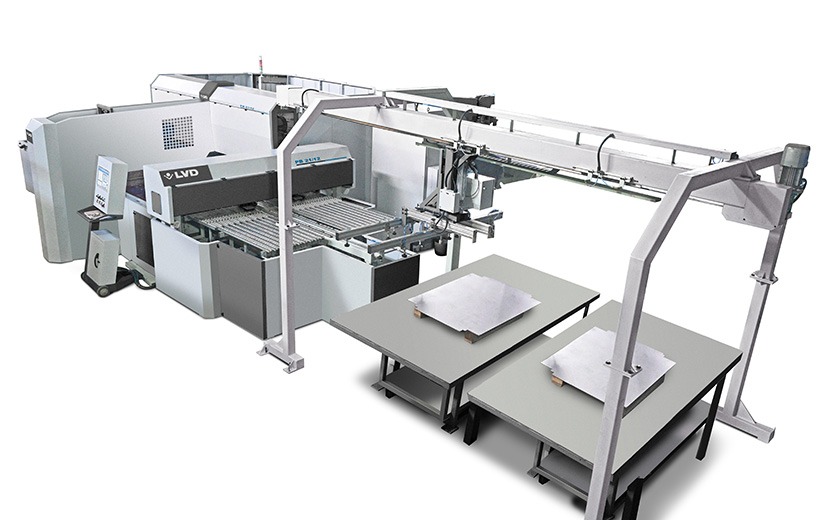

AUTOMATION ADVANTAGES

Puma’s shuttle table system allows one table to be loaded or unloaded while cutting on the other table, keeping throughput at its peak. Table changeover takes just 35 seconds.

To maximize laser cutting output and processing efficiency, Puma can be equipped or retrofitted with any MOVit modular automation system, including Compact Tower (CT-L) for loading, unloading and material/parts storage, Flexible Automation (FA-L) advanced load/unload system, Tower Automation System (TAS) single or double-tower storage, or Warehouse Automation System (WAS) customizable storage tower system.