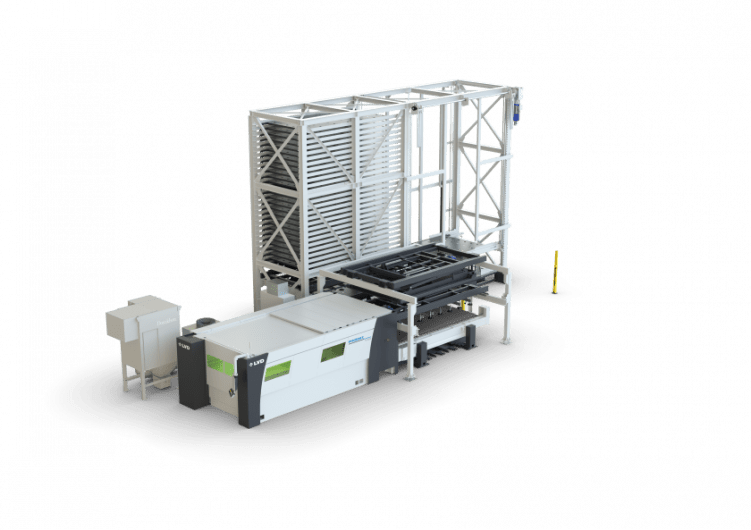

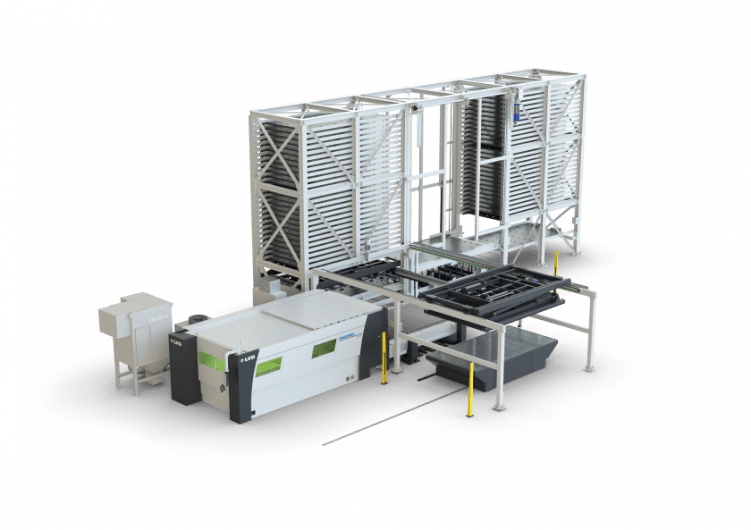

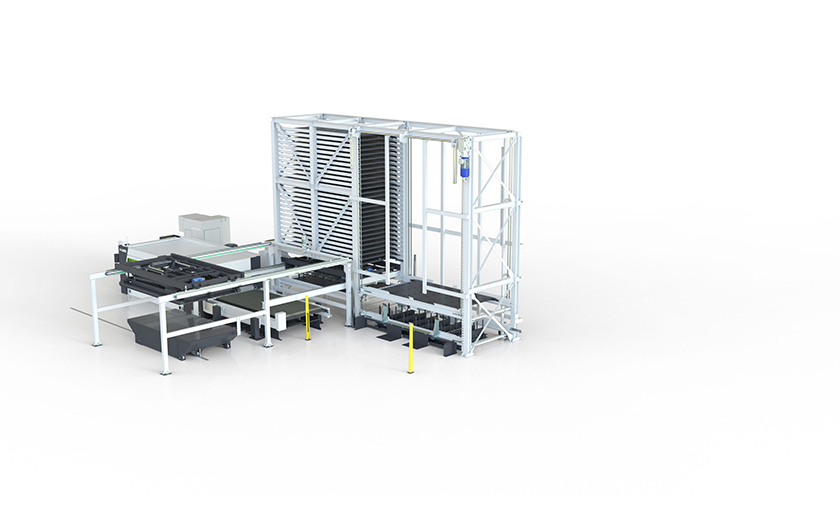

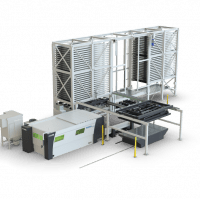

Tower Automation System (TAS)

Highly configurable tower storage system

TAS is designed to keep material flow continuous, production uninterrupted, and sheets and parts organized efficiently. The system connects up to two towers and two machines integrating standard modules in a flexible way to guarantee smooth transition from raw material to finished parts.

- 120" x 60", 160" x 80", 240" x 80" sheet sizes

- Handles materials up to 1.25"

- For Phoenix FL-3015, Phoenix FL-4020, Phoenix FL-6020

- For Puma 3015, Puma 4020, Puma 6020