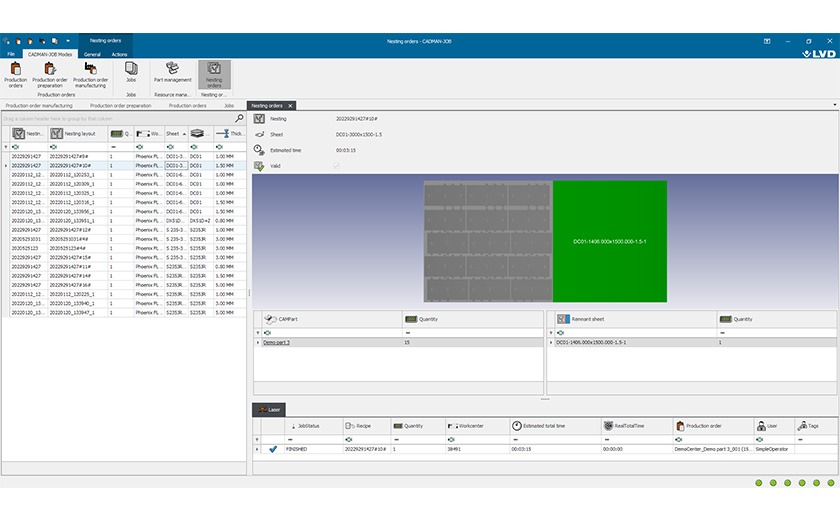

CADMAN-JOB

Improved process flow

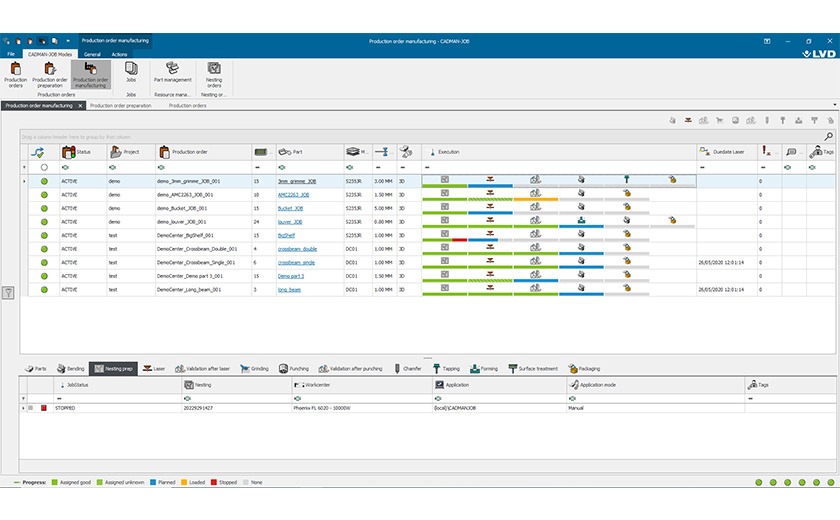

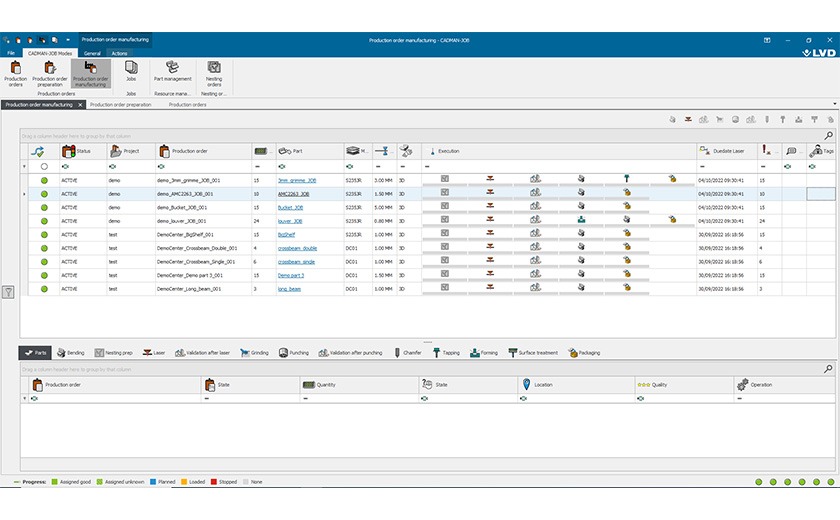

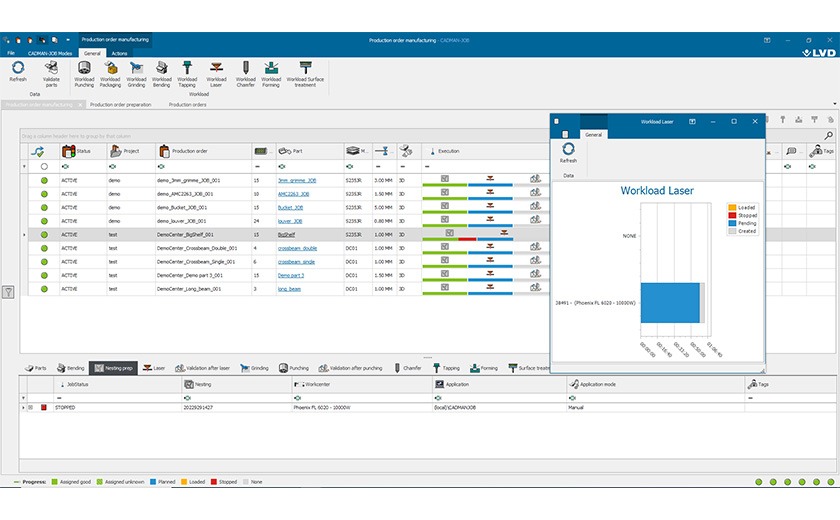

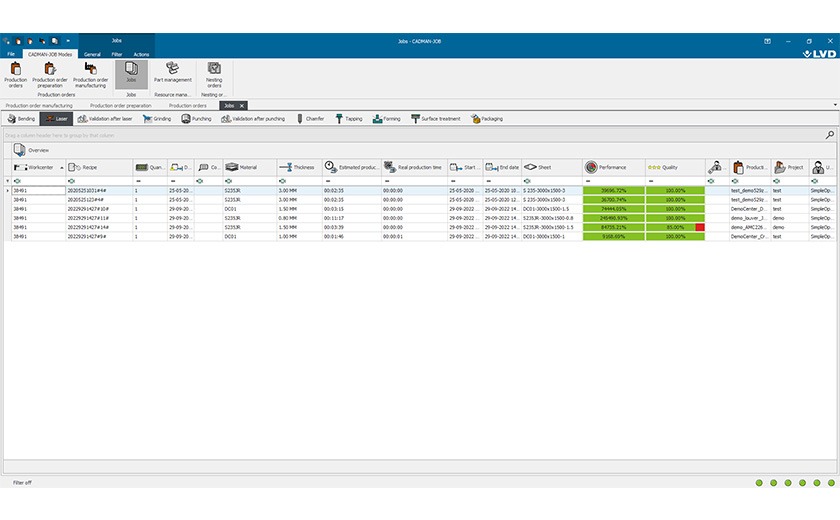

CADMAN-JOB serves as central production control to improve a workshop’s overall process flow. It connects the front office and shop floor to manage jobs for increased throughput, minimized set ups and streamlined work flow, providing real-time visibility and full transparency of the sheet metal fabrication process.

- Paperless flow from front office to workshop

- Connects the central database, ERP, CAM and workshop

- Generates, classifies and groups jobs for sheet metal fabrication