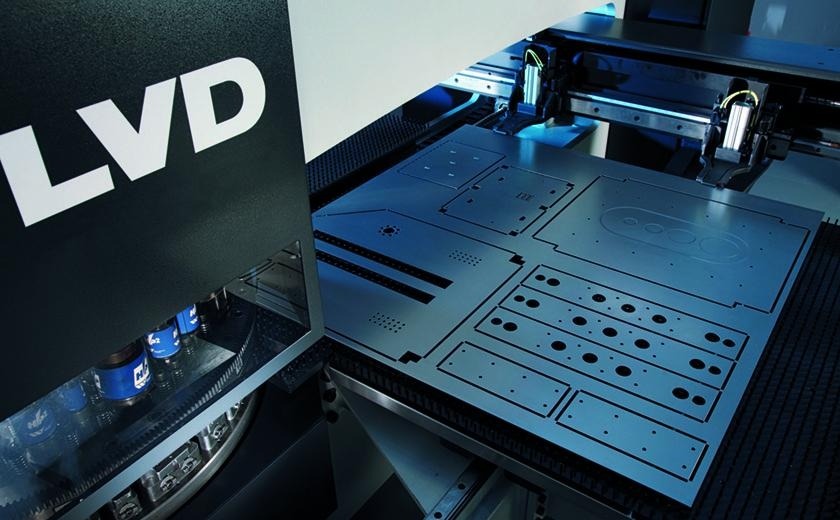

Strippit P

Strippit P is a cost-effective punching machine that’s ideal for prototyping and short run applications and for cell manufacturing. The ram system, rugged frame and CNC control deliver tight tolerances and consistent punching accuracy. The control is easy to use and operate.

- 33-station turret

- 20 tons of punching force

- 49.2" x 49.2", 49.2" x 98.4", 60" x 98.4" formats

Highlights

33-station turret

A 33-station turret features two 3.5" stations and three 2" stations. Every station has the flexibility to accept shaped or round punches and dies

Forming flexibility

A generous 0.984" feed clearance distance between upper and lower turret facilitates forming operations.

Smart Clamp

Automatically determines work clamp locations based on tool size, providing the smallest possible no punch zones to maximize sheet usage.

Quick-change die holders

Die change system offers easy and quick die changes of 15 seconds.

Fanuc control

The renowned Fanuc 0iP control features a self-prompting color display making Strippit P easy to operate.

CADMAN-P programming software

Powerful CAM software features a number of automated processes such as punch sequencing macros, automatic tool selection, clamp positioning and others to maximize punching machine productivity.

Technical data

| P-1212 | P-1225 | P-1525 | |

| Maximum punching capacity | 20 metric tons | 20 metric tons | 20 metric tons |

| Maximum material thickness | 0.250" | 0.250" | 0.250" |

| Punching accuracy | ± 0.004" | ± 0.004" | ± 0.004" |

| Repetitive accuracy | ± 0.002" | ± 0.002" | ± 0.002" |

| P-1212 | P-1225 | P-1525 | |

| 1 mm pitch | 650 HPM | 650 HPM | 650 HPM |

| 25.4 mm pitch | 300 HPM | 300 HPM | 300 HPM |

| Feed clearance | 0.984" | 0.984" | 0.984" |

| Nominal worksheet size | 49.2" x 49.2" | 49.2" x 98.4" | 60" x 98.4" |

*material thickness + tip recess + die penetration

| P-1212 | P-1225 | P-1525 | |

| Brush table* | up to 174 lbs. | up to 174 lbs. | up to 174 lbs. |

| Work clamp | 2 | 2 (optional 3rd clamp) | 2 (optional 3rd clamp) |

*at reduced speed

| P-1212 | P-1225 | P-1525 | |

| Turret configuration | 33 stations | 33 stations | 33 stations |

| Auto-index stations | 3C - Ø 2" | 3C - Ø 2" | 3C - Ø 2" |

| Maximum tool capacity* | 33 | 33 | 33 |

| Wheel Tool capacity | x | x | x |

| Tapping Tool capacity | x | x | x |

| Angular positioning accuracy | ± 0.05 degrees | ± 0.05 degrees | ± 0.05 degrees |

| Controller | Fanuc OiPD | Fanuc OiPD | Fanuc OiPD |

| Combined positioning speed X-Y | 82 m/min. | 82 m/min. | 82 m/min. |

| Tool change time | 1 sec. | 1 sec. | 1 sec. |

*with Multi-Tool

| P-1212 | P-1225 | P-1525 | |

| Average power consumption | 6.6 kW | 6.6 kW | 6.6 kW |

| Standby operation | 3.0 kW | 3.0 kW | 3.0 kW |

| P-1212 | P-1225 | P-1525 | |

| Automatic load/unload (PA) | - | - | - |

| Compact Tower (CT-P) | - | - | - |

| Flexible Automation (FA-P) | - | - | - |

| Bin sort | - | - | - |

| Robot pick/sort | - | - | - |

| Tower Automation System (TAS) | - | - | - |

| Warehouse Automation System (WAS) | - | - | - |

| Extended Tool Magazine (ETM) | - | - | - |

| Tool lubrication system | x | x | x |

Specifications subject to change without prior notice.

Options

ABS automatic tool lubrication system

Air blow system automatically lubricates the punch and guide to help ensure efficient tool stripping and extend the time between regrinding.