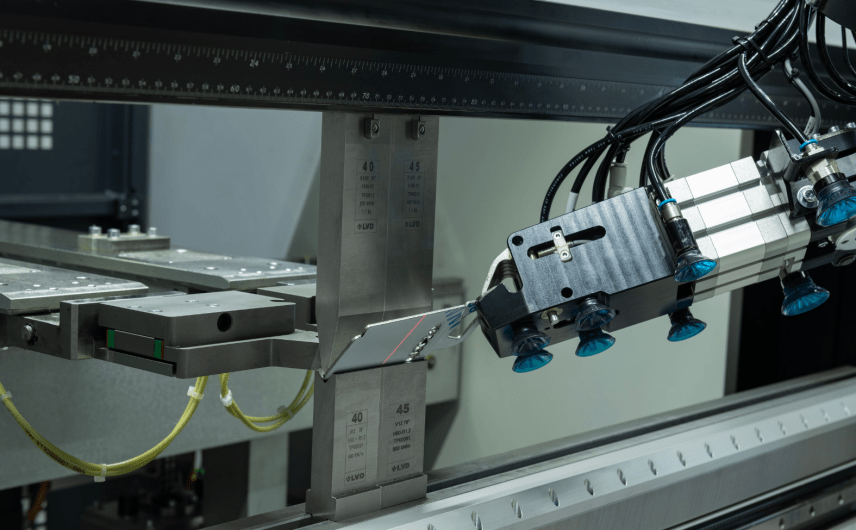

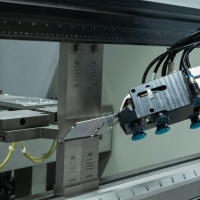

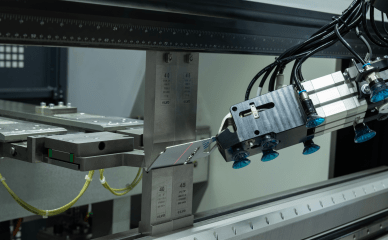

RBS 4

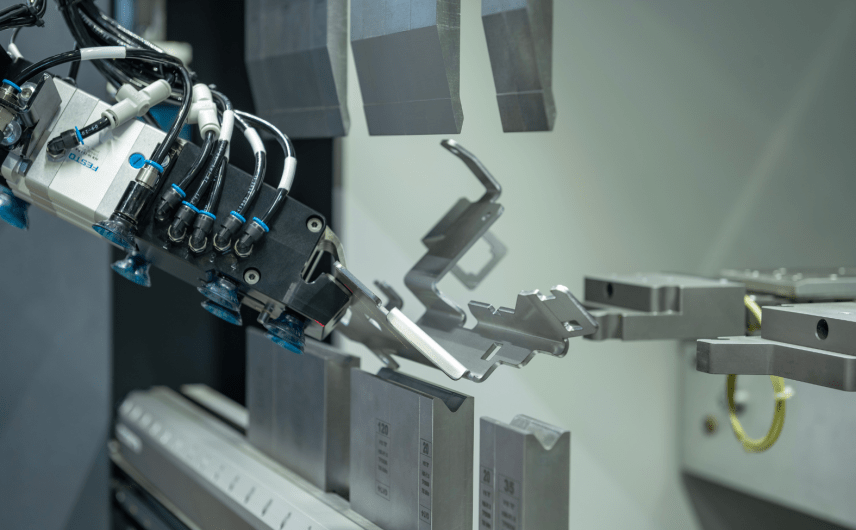

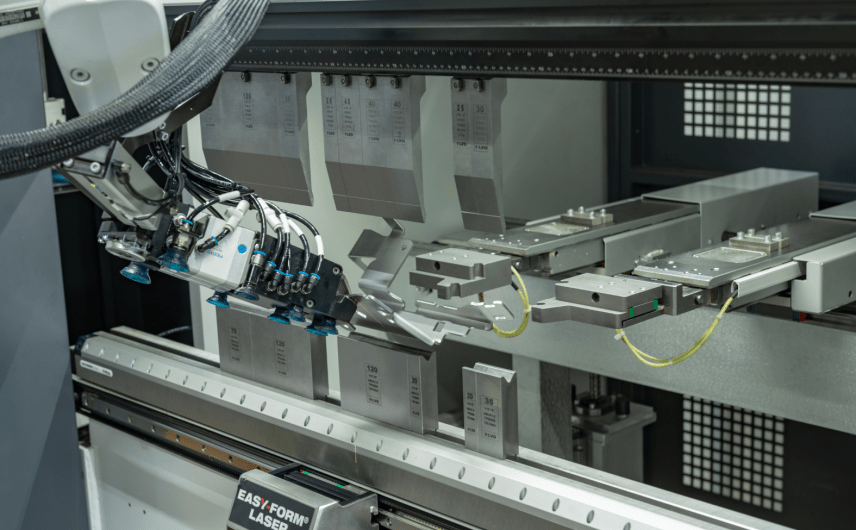

Robotic Bending System for small parts

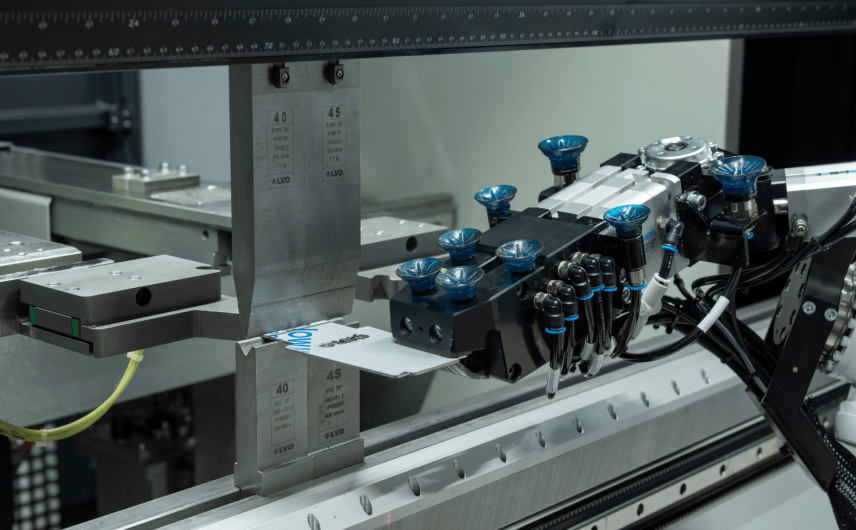

Starting from RBS 4, you configure a compact robotic cell for bending small parts in a fast and cost-efficient manner. Programming is handled completely offline - with no robot teaching required.

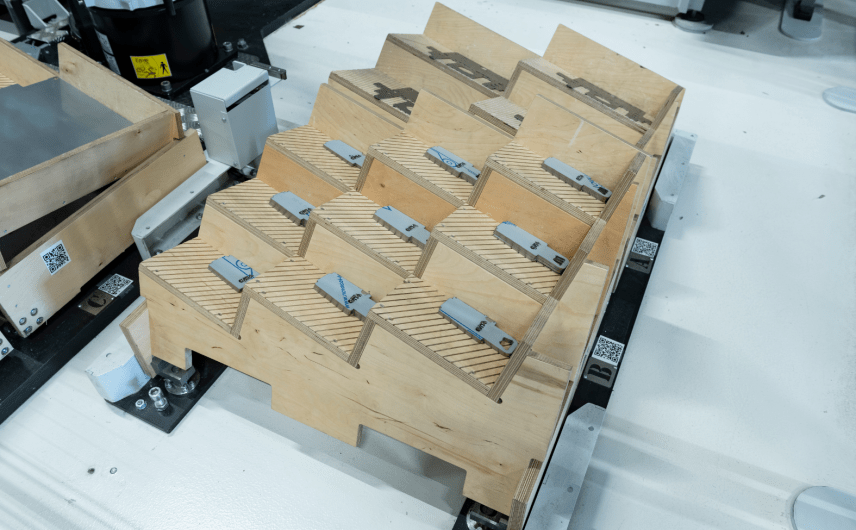

- Part size up to 23.6" x 15.7", weight up to 8 pounds

- Profile length: max. 23.6"

- Press brakes: Dyna-Press Pro (EFL) or PPED

- 59" or 78.7" bending length and 40 or 50 ton pressing force