MARK SCANLAN:

LNS Turbo is a machine tool peripheral manufacturer. We supply all aspects to fit onto any machine tool be it an input or an output. We have a head office and two factories in Switzerland. We have a factory here in the UK, one in Italy, three in North America and then we also have a factory in Taiwan, one in China and one in Japan.

We bought our first LVD press brake when the factory first opened almost 25 years ago.

STEVE KIRK:

It was the only press brake we had. It was all we could afford at the time and we used it for 20 years.

MARK SCANLAN:

Since then the partnership has just continued to grow. The business has evolved because we're very much focused on end-user markets and as we've grown we've changed that to work with OEMs and dealers to have more stability in terms of orders and repeatability.

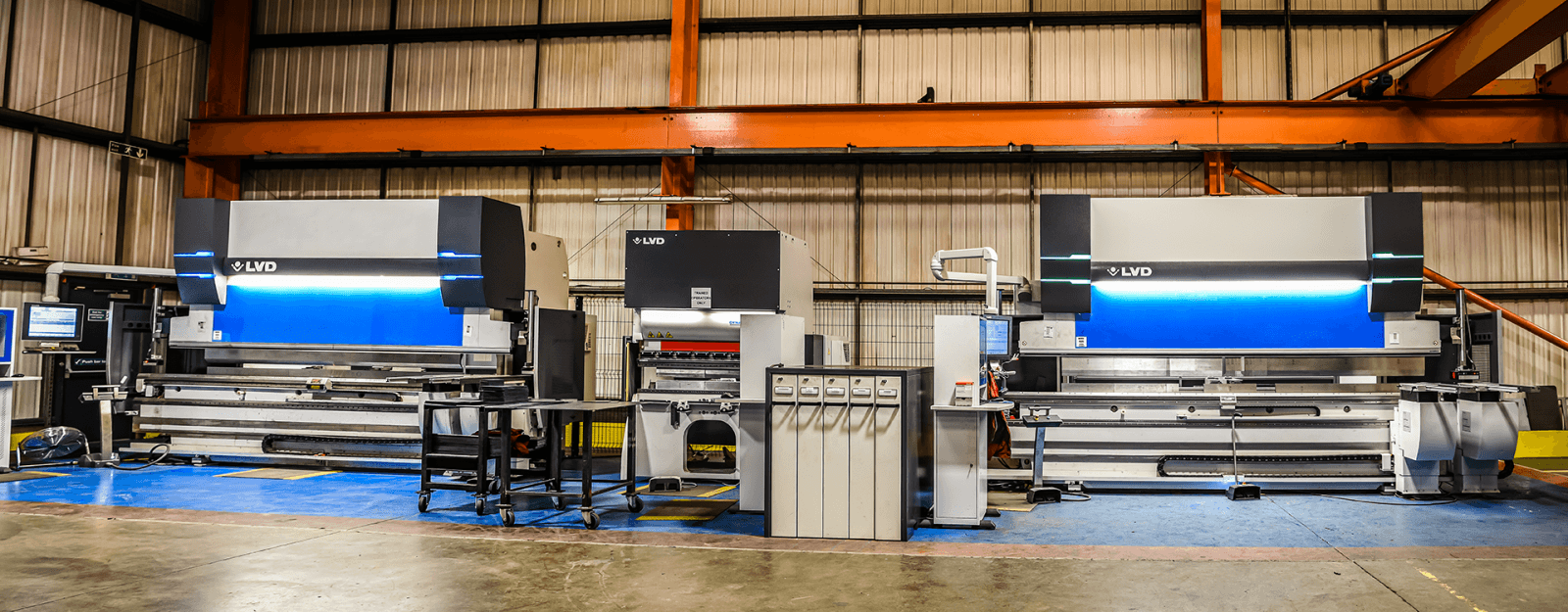

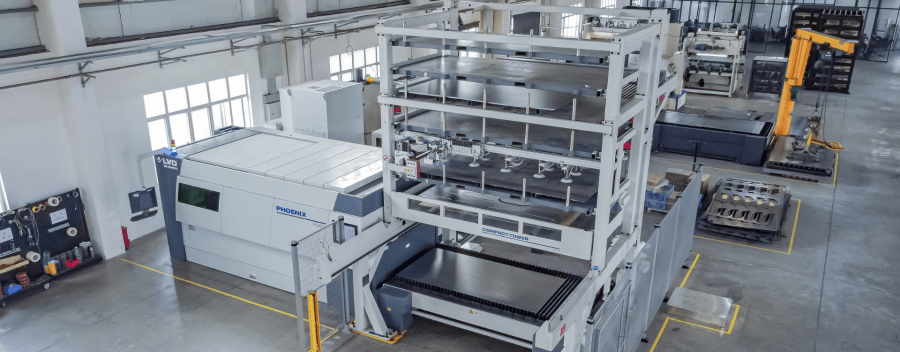

Here in the factory we had one laser and one press brake. We've now upgraded to one LVD laser and stacking tower, two LVD press brakes and an LVD Dyna-Press.

The logic to move and introduce a laser, as well as the press brakes, was the intuitive control. The CADMAN software then joined all those up. Choosing the Phoenix laser was a great change for us because we'd always used CO2 and we moved to a fibre, so more modern technology.

STEVE KIRK:

The main features for me are ease of use and the fact that we don't have people stripping the head down, making mistakes and creating waste.

MARK SCANLAN:

We bought the Compact Tower to go with the laser because we'd only purchased one in China and we saw the capabilities and the automation that it brought. So we went for a 10-station auto tower, which is the biggest one in the UK supplied by LVD. That's provided us with a new way of working, new automation in the processes. A lot of thinking to do in terms of how we’ll maximise that still, but it's a great potential for all of us.

STEVE KIRK:

I think it will change the business for the future. I think we have a huge amount of capacity now, where we didn't before. We have that ability to react to the customer's needs.

MARK SCANLAN:

It will change the business by giving us the opportunity to take on more orders, be more comfortable in our productivity. The automation of the tower, the laser and the press brakes combined now, allows us to double our output from 240 to 500 machines a month.

The service department of LVD has been great through all our years of using LVD equipment. They've always been responsive, helpful and allowed us to grow. Whenever we have a breakdown, there's always people who are very approachable. They'll get here as soon as they can, giving us the confidence to go and buy more equipment.