Strippit PX

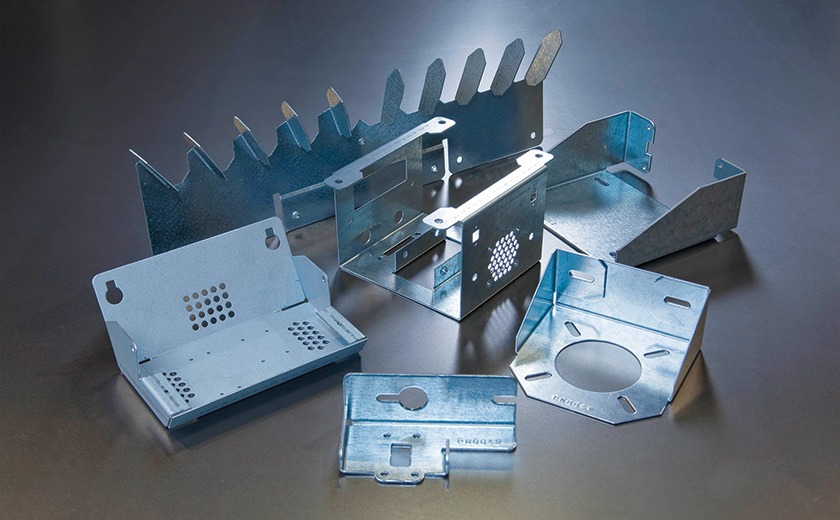

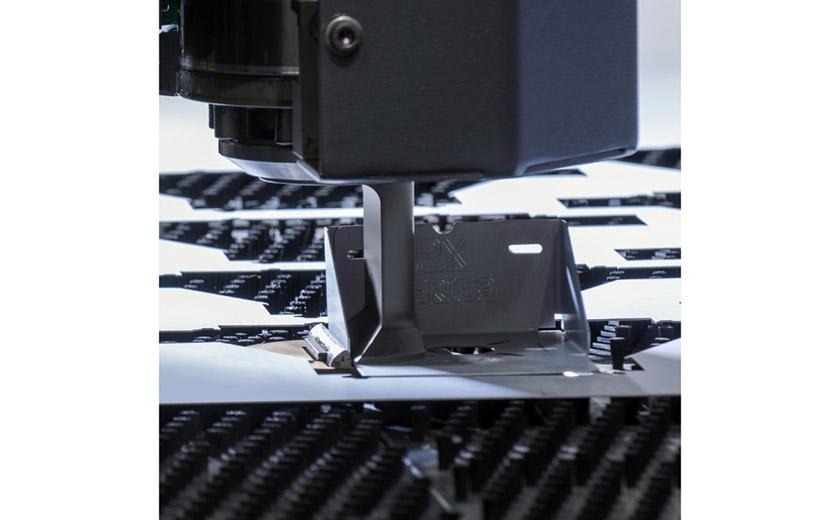

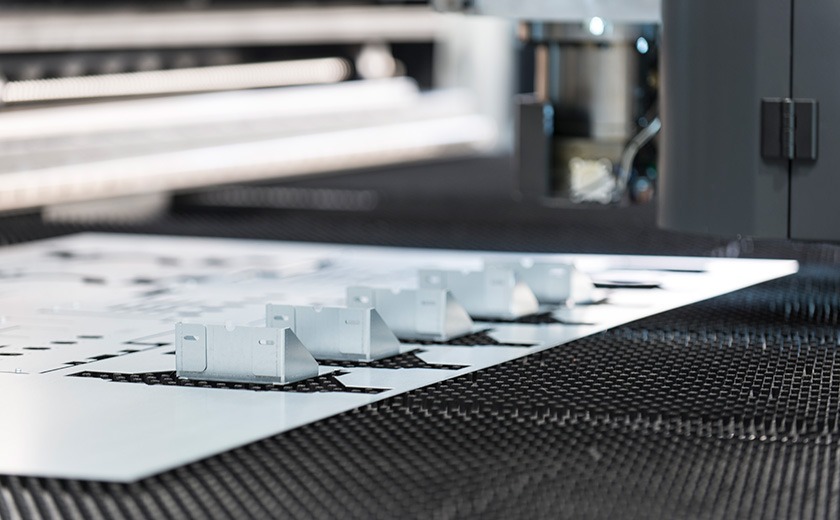

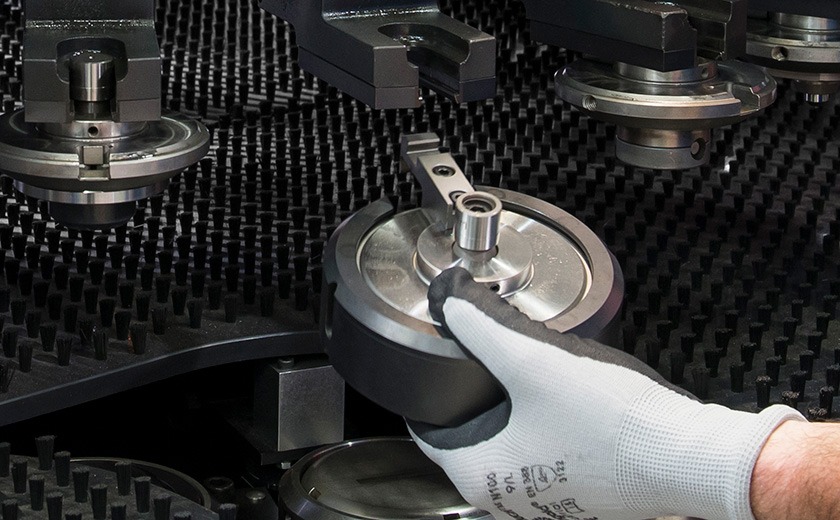

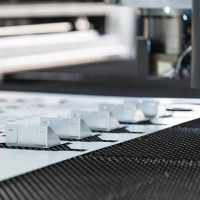

Advanced punching and forming

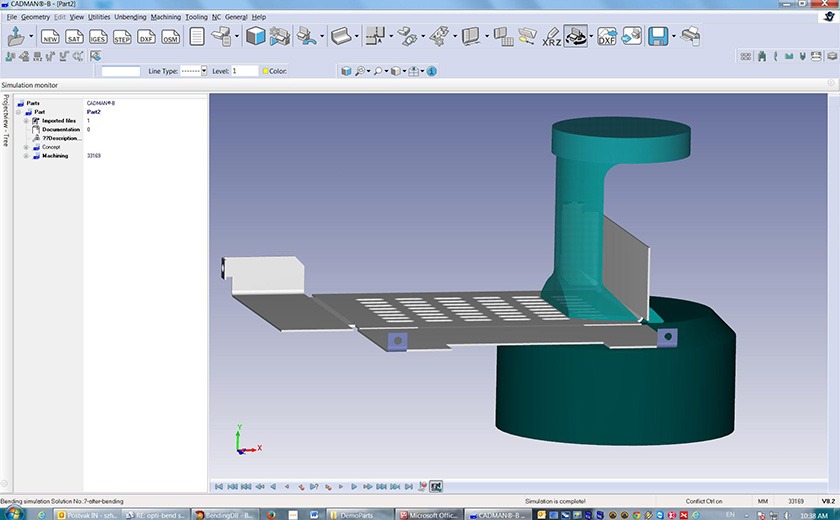

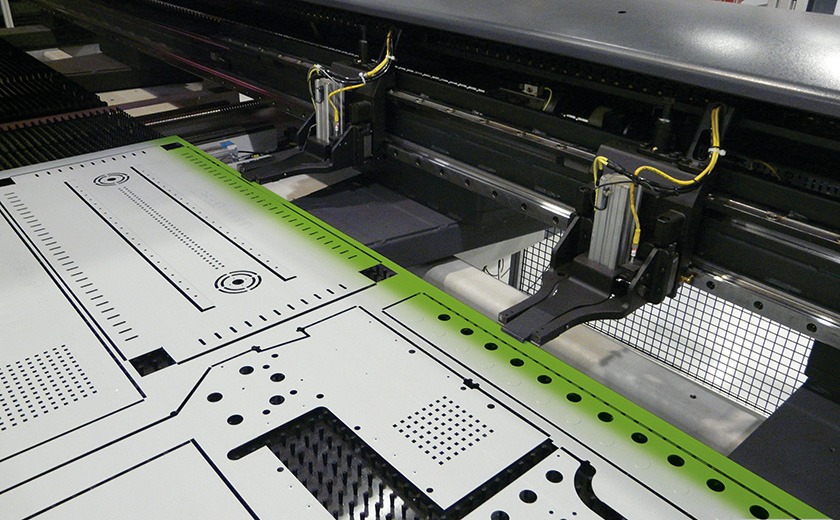

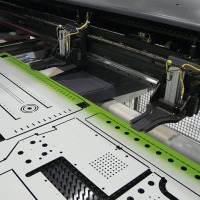

Strippit PX is a versatile machine, able to punch, bend, tap and form. Its single-head design features up to 200 tools with all-tool rotation so each tool has the flexibility to rotate a full 360 degrees, and can be used at any angle anywhere on the sheet.

- Form and bend materials up to 3"

- Punch up to .250"

- 20-ton capacity in 49.2" x 98.4" or 60" x 120" formats

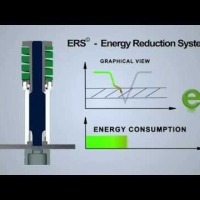

- Smart factory - Industry 4.0 compatible