42 years serving bakeries

It all started in the barn next to his house in Gommegnies, where Pierre Lancelot, an aeronautical engineer, designed from the ground up a totally new electric ventilated oven for the baking industry. He applied his knowledge and skills in aeraulics - the science and technique of treating and distributing air – to the field of baking. In 1980 Eurofours was born.

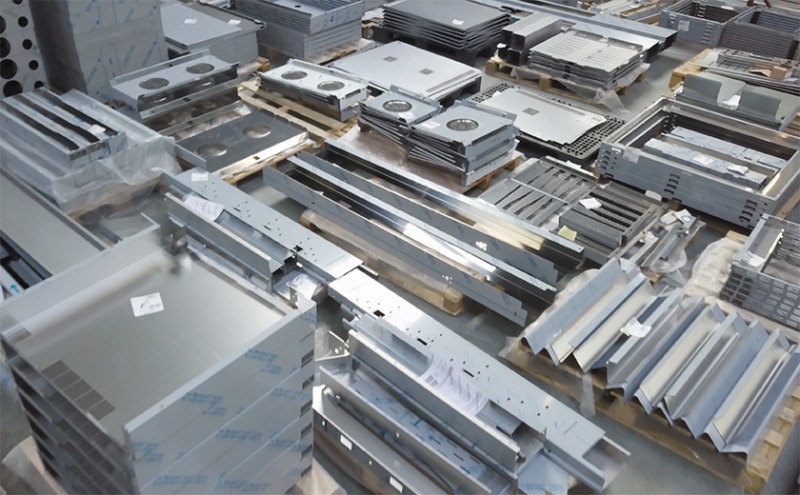

Today his sons Stéphane and Nicolas Lancelot run the company and Eurofours is the benchmark for ventilated ovens for bakeries and pastry shops. New facilities were established in Gommegnies and La Longueville, and busy production lines are driving the company’s expansion. After a series of acquisitions, the company has become well-established in the baking sector with around 150 employees over three production sites.

A niche market

Eurofours produces equipment for bakeries, pastry shops as well as modular units used to heat pre-cooked baked goods and snacks. 90% of the sheet metal they use is thin (1.2/1.5 mm). The product range includes ventilated rack and deck ovens, low temperature controlled fermentation cabinets, chambers, and display cases. Eurofours can count many well-known names such as Le Nôtre, Ladurée, Paul, Banette, Bridor and Baguépi among its customers.

The company develops comprehensive designs for bakeries, providing them with all the displays and display cases they need. The ability to produce these ready-to-use solutions is one of its strengths. This niche market enables Eurofours to build around 3,000 ovens per year, achieving 70% of their turnover in France and 30% in exports to no less than 100 countries, mainly Canada and Asian countries.

“There is a lot of competition in our business,” says Mickael Rousseau, production & methods director, “but we are the only company that offers such a wide product mix, enabling us to propose and realise comprehensive solutions.”

Complete solution

In March 2020, LVD delivered and set up a Phoenix FL-3015 6 kW laser cutting machine with Compact Tower automation, as well as two press brakes: first a ToolCell 135/40 and later on an Easy-Form 9 80/25. In addition, the company has LVD’s CADMAN® software. The machines and software were installed right at the beginning of the Covid pandemic, which allowed the company to master the new equipment at its own pace.

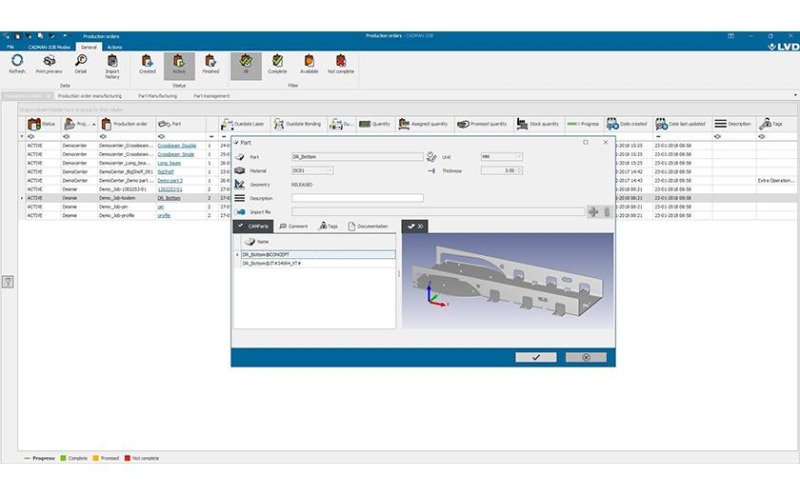

Yoan Khinache, sheet metal & methods manager, explains: “With the CADMAN suite LVD provided a complete solution. The connectivity between the software, our ERP system, the laser and the press brakes has significantly improved our manufacturing capabilities.” The Phoenix met Eurofours’ requirements in terms of power and cutting capacity in different materials and thicknesses.

The press brakes are equipped with LVD’s Easy-Form® Laser in-process adaptive bending system, which enables them to adapt to material variations such as sheet thickness, strain hardening and grain direction, thus guaranteeing the desired bend angle. As for the ToolCell, it was the automatic tool-loading and unloading system, resulting in a 30% time-saving, that convinced Eurofours.

Good results

“It was definitely time to replace our outdated machinery. We contacted three companies and decided on LVD. We wanted to have more flexibility, more just-in-time work while also reducing material waste, given the current price of stainless steel,” Rousseau underlines.

“We have a very good relationship with LVD,” adds Mr Khinache. “The demonstration they gave in their Experience Center with our parts was very impressive. It is also a plus that the LVD factory is only an hour and a half away from ours. As for bending, it was the time savings of the ToolCell automatic toolchanger and the Easy-Form Laser capabilities that convinced us.”

The results speak for themselves. Mr. Rousseau: “An important thing is that we have reduced the scrap rate by 20%, also thanks to the use of the Easy-Form. The CADMAN software allows us to better manage our stock by having a faster reactive production lead-time, which in turn ensures greater profit margins.

“We have also halved the workforce in the sheet metal workshop. These people were moved to the assembly workshops.

“The investment also enabled us to manufacture the insulation panels for our fermentation equipment, which represented a big purchase cost. We also brought inhouse all subcontracted sheet metal cutting in higher thicknesses.”

He concludes: “We have a great partnership with the after-sales service, the development team and the sales manager, Mr Gallez. They are always attentive to our needs and can respond very quickly when needed.”

Françoise Soetens – Metallerie

Company profile

Company Eurofours SA

Since: 1980

Industry:

Manufacturer of bakery ovens, fermentation cabinets and chambers, pastry, chocolate and bakery display cases.

Works with :

Stainless steels, aluminum and special alloys

Equipped with :

- Phoenix FL-3015 6 kW with Compact Tower

- ToolCell 135/40

- Easy-Form-9 80/25

Software:

- Software : CADMAN-SDI, CADMAN-B, CADMAN-L, CADMAN-JOB et Touch-i4

Eurofours was founded in 1980 by Mr Pierre Lancelot. At Eurofours we have approximately 150 employees who realise a turnover of some €20 million.

Eurofours specialises in manufacturing commercial ovens, accounting for approximately 60% of our production. We also manufacture fermentation cabinets and display cases for baked goods and chocolates. We export to some 100 countries.

Why did we choose LVD’s laser cutting and bending equipment?

The technology opened up new manufacturing possibilities, enabling us to make finished products that are better quality and slightly more sophisticated.

LVD provided us with a complete solution, from the software to the production equipment. We have the complete CADMAN software suite. We use CADMAN-B for the bending process and CADMAN-L to program the laser cutting machine. We also have CADMAN-JOB, the interface between our ERP system and the machines.

As for machinery, we opted for a laser cutting machine with a load/unload tower. Because we manufacture a variety of products, we use many different materials. We wanted a load/unload tower so the machine could function with maximum autonomy.

We also chose an automated press brake, a 4 metre, 135 ton ToolCell. It’s automated, meaning it loads and unloads the tools itself. This represents 30% of the time the operator spends on loading and unloading tools. It also features Easy-Form laser technology, a dynamic angle corrector that saves us having to calculate the grain direction, etc.

In addition to the ToolCell we invested in a smaller machine, an Easy-Form, which enables us to process much smaller parts with no more than one or two bends, freeing up the ToolCell for the big jobs, which take a lot more work. Each week, we ask our ESP system what we need for our production for the coming week or the next 2, 3 or 4 weeks. It details our sheet requirements. This work order is directly integrated into CADMAN-JOB. The software checks several things: whether it knows the part, whether we have already bent it and whether it’s technically feasible. It also gives us a cost and time analysis.

CADMAN-JOB generates a job list, which is a work order for the workshop. We import the program into the machine, which then executes the cutting sequence it’s been given. Once the work order is finished, the pallet is unloaded from the storage tower and placed on a separating table. At this table there is a tablet computer. The operator checks the part and enters into the tablet whether or not it’s acceptable. If the part is OK, the operator assigns it to an available trolley. When this is done a label is generated that contains several elements such as the work order, which is the work order from our ERP system, and it also states whether the part can go straight to assembly or needs to be bent.

As a result we now have 20% less waste material, giving us a bigger return on investment. We have also reduced the labour force by half in our sheet metal workshop. These workers have been reassigned to our assembly workshops, which has also improved our ROI. The insulation panels for our fermentation equipment, which used to be a major purchase cost, are now also manufactured in-house.

We also brought all sheet metal cutting of thick materials, which we used to outsource, back in-house. These are things that weren’t possible before.