The first verifiable mention of the Taupitz company dates back to 1807. From other sources that cannot be verified with certainty, we know that the Taupitz family owned blacksmith shops here in the region several centuries before. In those days, shoeing and repairs for local farmers were the company's main activity.

Today we are primarily a sheet metal working subcontractor but we have also already helped customers develop products for sanitation and automotive applications. We operate almost exclusively in Germany. Our customer base ranges from regional metalworkers to international mechanical engineering groups. We currently have 25 employees. The facility boasts approximately 2,000 square metres of office and production area. We are forecasting sales of €3 million this year.

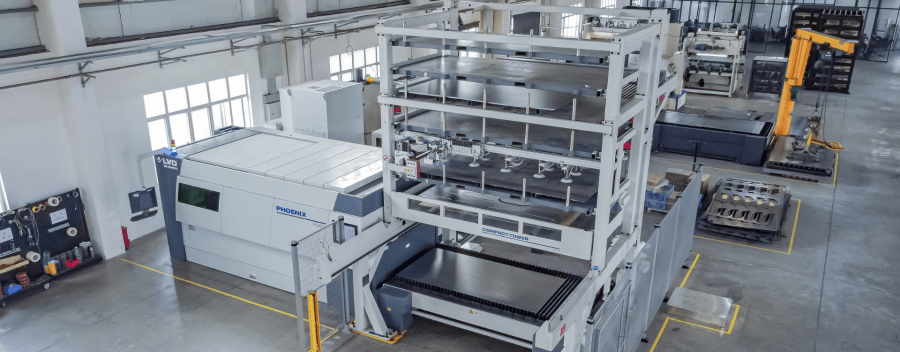

This year marks 30 years that we have worked with LVD, who is a strategic partner for us. We have worked very closely with the LVD staff for decades and we have very high confidence in the performance of LVD machines. We are pleased that LVD, as a close partner, keeps abreast of technology. We purchased our first LVD press brake in 1992. In 1994 we added a Delta punching machine. With our first laser cutting machine, an LVD Impuls, we were able to easily process complex sheet metal contours using a laser beam. The demand for such components grew steadily so that in 2007 we bought an Axel laser from LVD. With a successor to this laser in 2015 we broke new ground. We invested in modern 3D design software and also in a modern fibre laser from LVD, which work hand in hand.

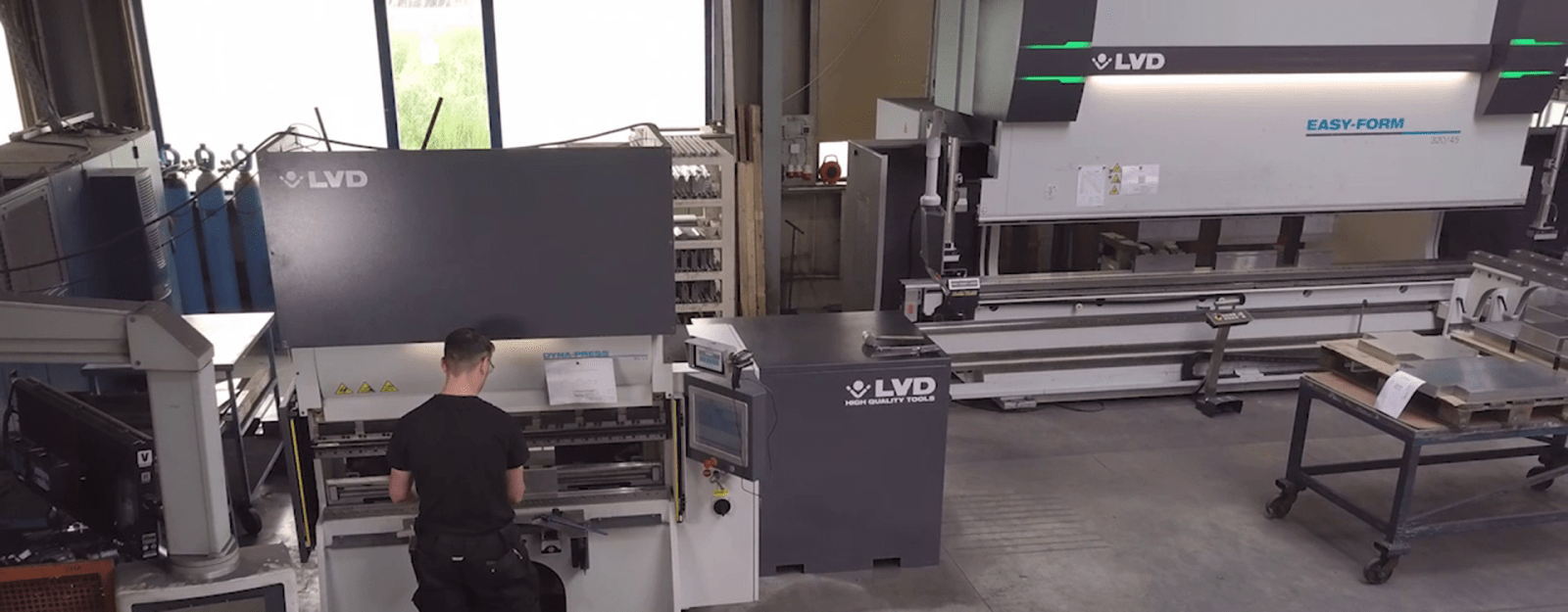

The Phoenix has increased our sales by more than 40% from 2015 to 2020. During this time we acquired additional LVD press brakes, a Dyna-Press and an Easy-Form. There, too, we were able to make considerable improvements using technologies like adaptive bending to increase throughput. And most recently with our new Strippit M punching machine we've significantly reduced the need for secondary operations. In some cases we have succeeded to divide throughput times by four.

The future will require both speed and diversity. Our customers are demanding faster turnaround times and want a higher degree of customisation. Top quality is no longer requested, it is considered self-evident. There is also an increasing need for real-time information on order progress, price and manufacturing capabilities. Customers are already used to getting this service in the private sphere from online retailers and will increasingly demand this in the B2B environment as well. Automation and handling solutions will unburden employees, who will have to work longer in the future and whose qualifications are of great importance to our company. In a further step, such systems will even partially or completely make up for a lack of labour.

Robotics play a key role in this regard, even in small and medium-sized companies. We are currently in a process of transformation and plan to use the LVD software together with the data from the controls even more intensively. This is where the consistency of the offline software comes in and, most of all, the easy and convenient user interface. Both the work preparers and machine operators quickly got the hang of the tools, which is a big advantage for us. Also important is our excellent collaboration with the entire LVD team. The knowledge and competence of the sales people, the quality of the machine construction, the level of training and service expertise is very high.

The personal contact coupled with fast solutions when compared to other suppliers is of paramount importance to us. Working with LVD over the last 30 years we have always found them to be a reliable, leading-edge partner. With each new investment we've found that the throughput times had been significantly reduced. On the one hand, this has enabled us to considerably boost our sales and on the other hand to service our customers much faster and with high quality.