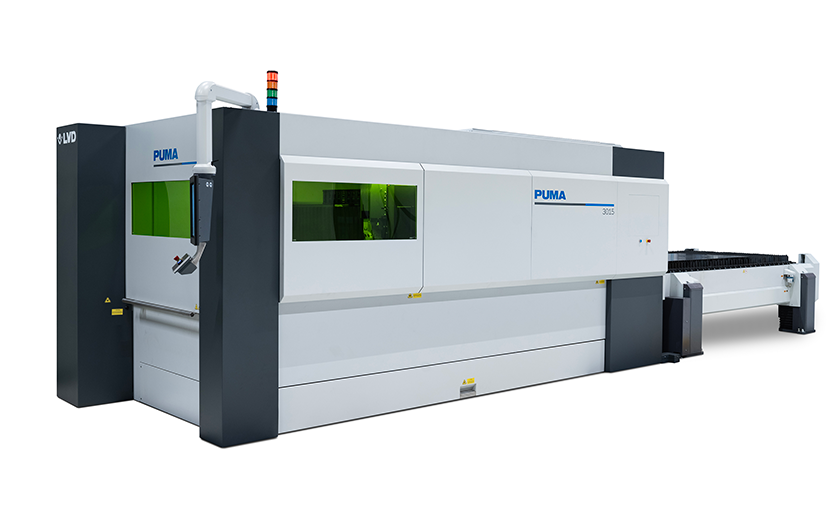

Puma

Puma offers high-productivity laser cutting at a lower total cost of ownership. Designed to operate as economically as possible, Puma is a robust machine able to handle a range of applications to maximize the value of your investment.

- 3, 6, 12 or 20 kW laser source

- Automation compatible

- Sheet size formats: 3050 x 1525 mm, 4065 x 2035 mm, 6160 x 2035 mm,

Puma 6525: 6400 x 2500 (straight cutting), 6100 x 2000 (bevel cutting, bevel head optional) - Smart factory - Industry 4.0 compatible

Highlights

Lower total cost of ownership

Puma focuses on getting the job done, utilising field-proven production methodologies in a lower-cost design. The machine features cost-effective components selected for their quality and reliability. Lower purchase, operating and spare parts costs will ultimately reduce the cost per part.

All-round performance

Puma provides all-round performance at an affordable price point, processing a wide range of material types and thicknesses with high repeatability. Machine accuracy is ensured by the welded steel frame construction, a feature of all LVD flatbed lasers.

It provides maximum stability and minimizes deformation caused by high acceleration.

Agility to take on any job

Designed with cost-effective operation in mind, Puma certainly doesn’t compromise on versatility and offers peace of mind that your cutting operations will run smoothly. The machine features a range of options that increase its capacity.

Touch screen control

LVD’s 19-inch Touch-L control simplifies machine setup and provides a graphical user interface that is easy to use and follow for the operator.

Automatic shuttle tables

The machine maximises uptime with an integrated shuttle table system that allows one table to be loaded/unloaded while cutting on the other table. Table changeover is complete in just 35 seconds.

CADMAN® software suite

A full suite of software modules create a fully integrated process flow, including CADMAN-L laser cutting programming software, CADMAN-SDI drawing importer, CADMAN-JOB real-time data collection, job tracking and ERP connection, as well as a Touch-i4 tablet for KPI performance indication and sorting and validating parts.

Technical data

| Puma 3015 | Puma 4020 | Puma 6020 | Puma 6525 | |

| Maximum sheet size | 3050 x 1525mm | 4065 x 2035 mm | 6160 x 2035 mm | 6400 x 2500 mm* |

| X-axis travel | 3185 mm | 4200 mm | 6280 mm | 6510 mm |

| Y-axis travel | 1560 mm | 2070 mm | 2070 mm | 2600 mm |

| Z-axis travel | 130 mm | 130 mm | 130 mm | 130 mm |

| Maximum sheet weight on table | 1050 kg | 1600 kg | 2500 kg | 3600 kg |

| Table changeover time | 35 sec. | 39 sec. | 48 sec. | 50 sec. |

| Maximum positioning speed X-Y | 140 m/min | 140 m/min | 140 m/min | 140 m/min |

| Maximum positioning speed Z | 30 m/min | 30 m/min | 30 m/min | 30 m/min |

| Repetitive accuracy | +/- 0.025 mm | +/- 0.025 mm | +/- 0.025 mm | +/- 0.025 mm |

| Positioning accuracy** | +/- 0.050 mm | +/- 0.050 mm | +/- 0.050 mm | +/- 0.050 mm |

* Bevel cutting: 6100 x 2000 mm

** Achievable workpiece accuracy depends on the type of workpiece, pre-treatment and sheet size, as well as other variables. According to VDI/DGQ 3441.

Specifications subject to change without prior notice.

| Puma 3015 | Puma 4020 | Puma 6020 | Puma 6525 | |

| Length | 8825 mm | 13,000 mm | 17,200 mm | 17,200 mm |

| Width | 2560 mm | 6300 mm | 6300 mm | 6700 mm |

| Height (access door opened) | 3400 mm | 3360 mm | 3360 mm | 3900 mm |

| Approximate weight | 13,000 kg | 16,500 kg | 21,500 kg | 28,000 kg |

| Laser power | 3, 6, 12 or 20 kW | ||||

| Maximum cutting performance | 3 kW | 6 kW | 12 kW | 20 kW | |

| Mild steel | 15 mm | 25 mm | 30 mm | 45 mm | |

| Stainless steel | 12 mm | 25 mm | 30 mm | 30 mm | |

| Aluminium | 12 mm | 25 mm | 30 mm | 30 mm | |

| Copper | 6 mm | 8 mm | 15 mm | 15 mm | |

| Brass | 5 mm | 8 mm | 15 mm | 15 mm |

Options

Automatic nozzle changer

Fast and efficient, the automatic nozzle changer reduces non-productive time. It also performs automated nozzle inspection and cleaning to ensure reliable cutting results.

MOVit modular automation

Automate Puma for even greater productivity. Choose a MOVit Compact Tower (CT-L) for loading, unloading and material/parts storage, MOVit Flexible Automation (FA-L) advanced load/unload systems, MOVit Tower Automation System (TAS) single or double-tower storage, or MOVit Warehouse Automation System (WAS), customizable storage tower system.

Bevel head on Puma 6525

Bevel cutting offers a fast and cost-effective way to prepare material for subsequent welding operations or to create geometrical shapes.

Compressed air or mixed gas cutting

In addition to nitrogen and oxygen, compressed air or mixed gas can be used as cutting gas options. Compressed air can significantly reduce part costs and is ideal for high-volume jobs. Mixed gas provides high cut quality for projects that require high precision.