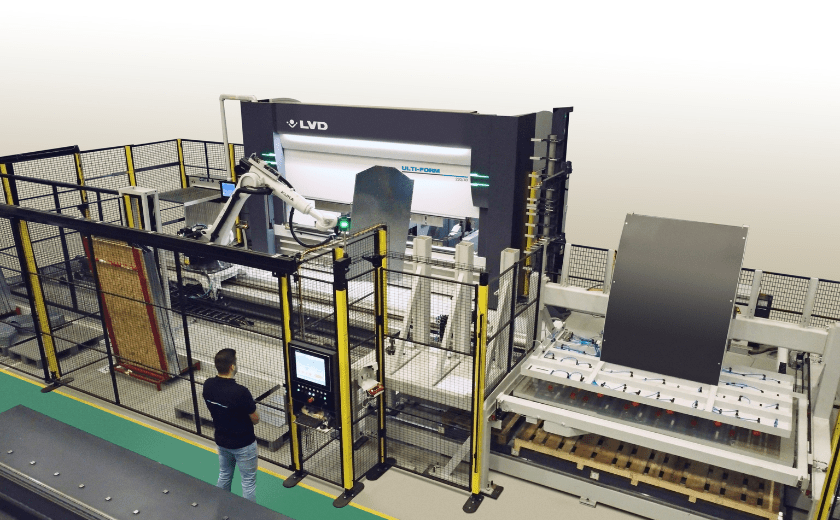

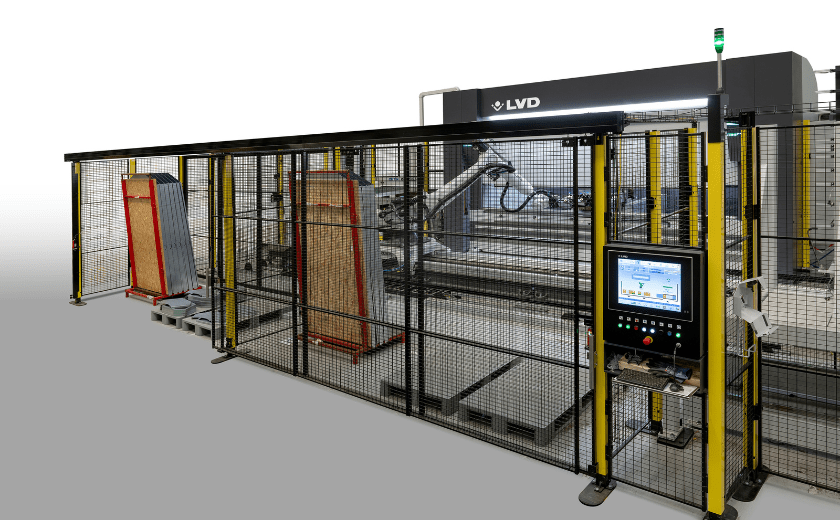

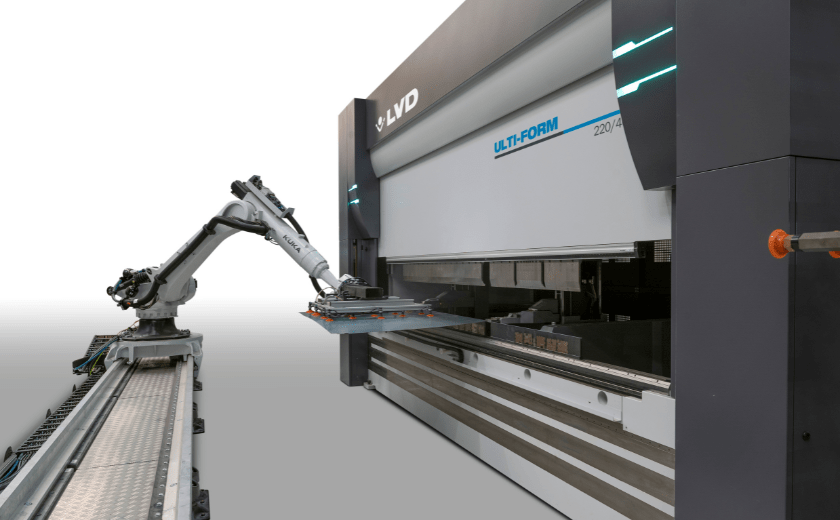

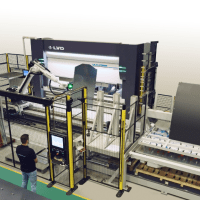

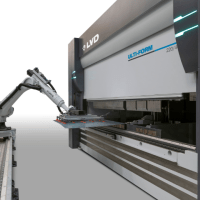

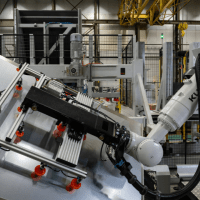

RBS 80

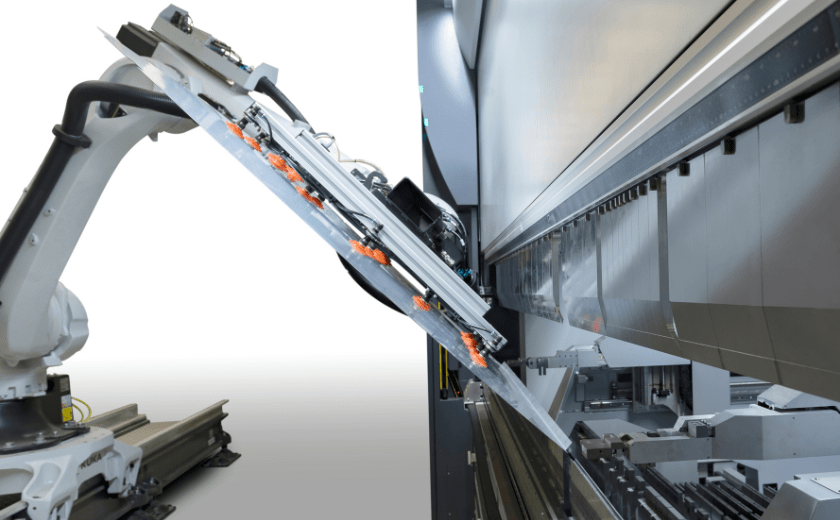

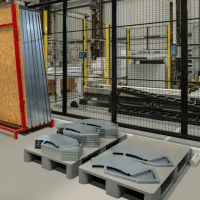

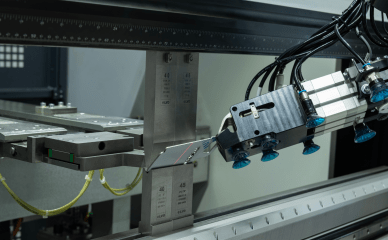

Robotic Bending System for large parts

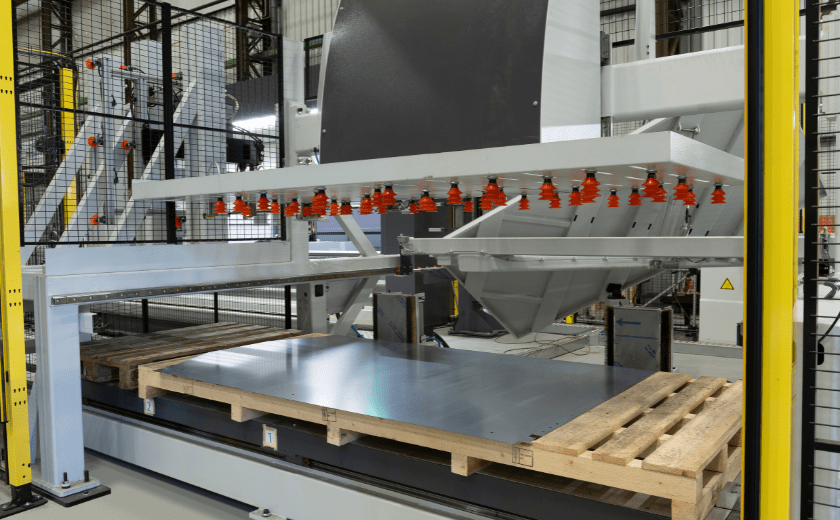

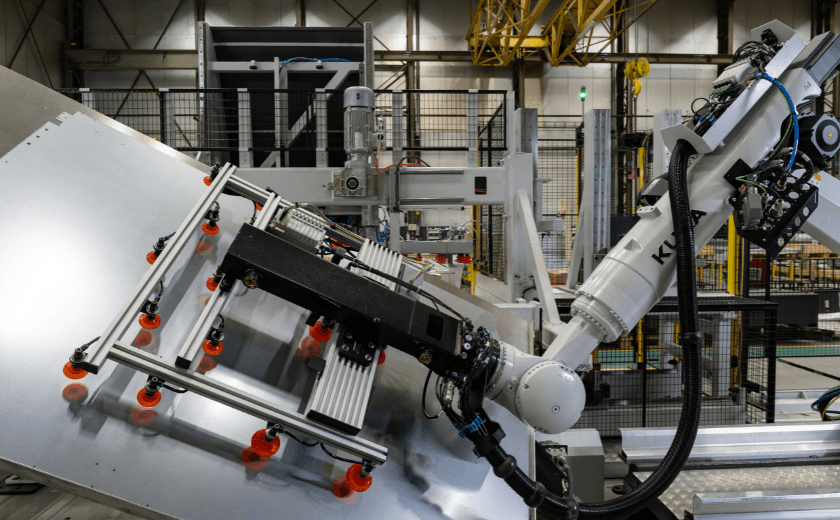

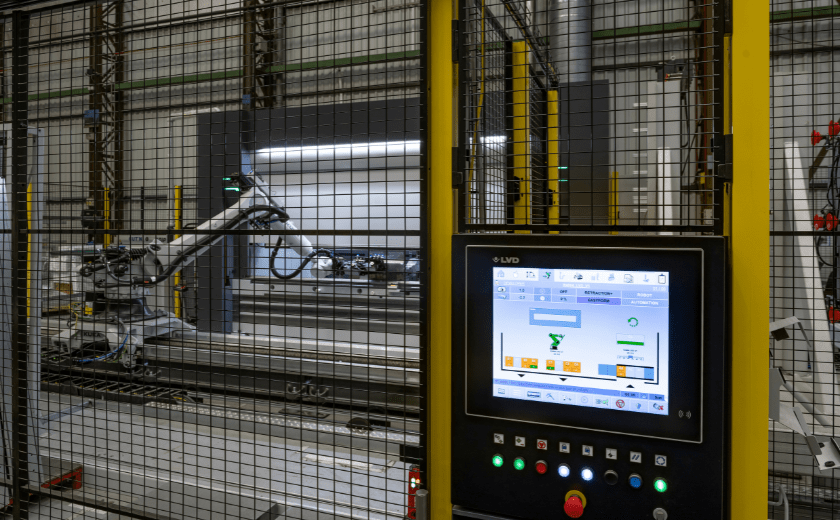

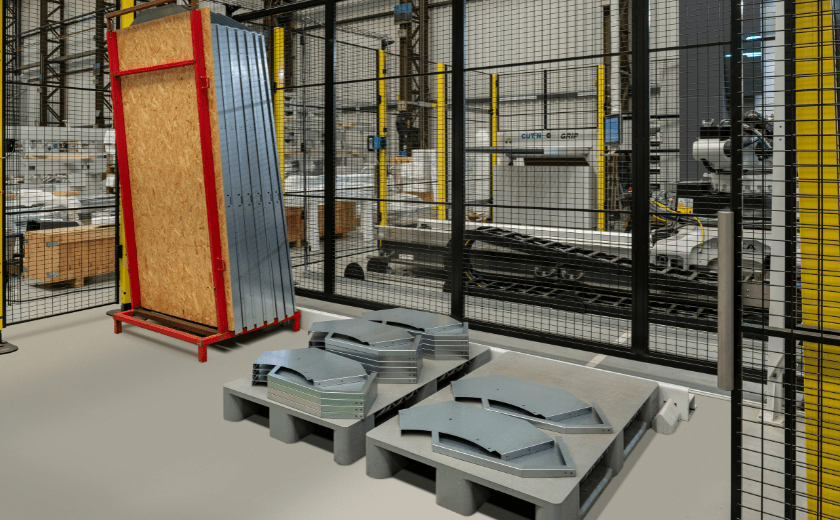

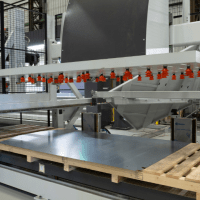

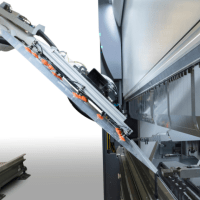

Based on the RBS 80 platform, you can configure a fully automated bending cell with a choice of robust press brakes, a robot on a guided rail, and multiple input and output options for smooth handling of heavy parts. Programming is done completely offline – with no robot teaching required.