Company Profile

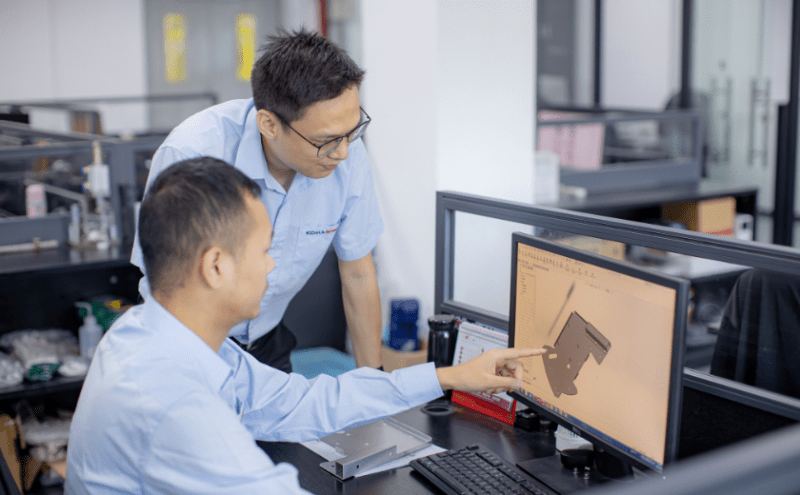

Company: KOMASPEC

Established: 2005

Location: Guangzhou, China

Industries served: Agriculture, mining, consumer goods, fitness equipment, automotive, recreational vehicles, construction

Materials: Cold/hot rolled steel, spring steel, aluminium, stainless steel, cold galvanized steel

LVD installations:

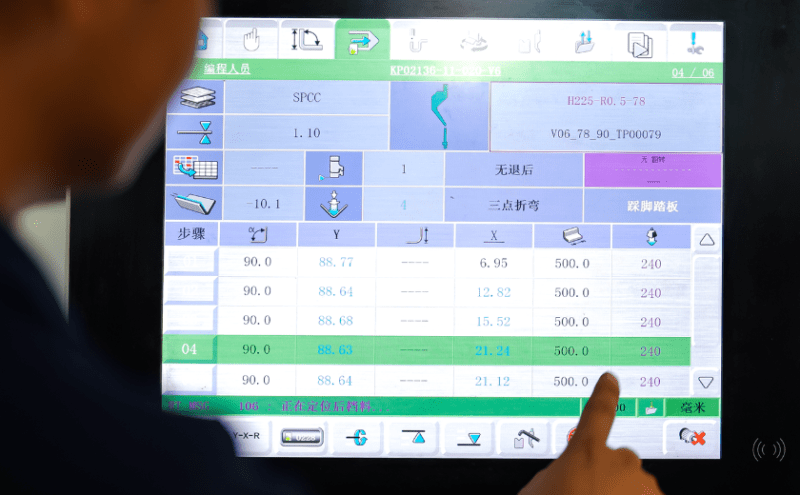

- Easy-Form® 80/15 and 80/25 press brakes

- Dyna-Press 24/12 press brake

- Dyna-Press Pro 40/15 press brake

- Dyna-Cell robotised press brake

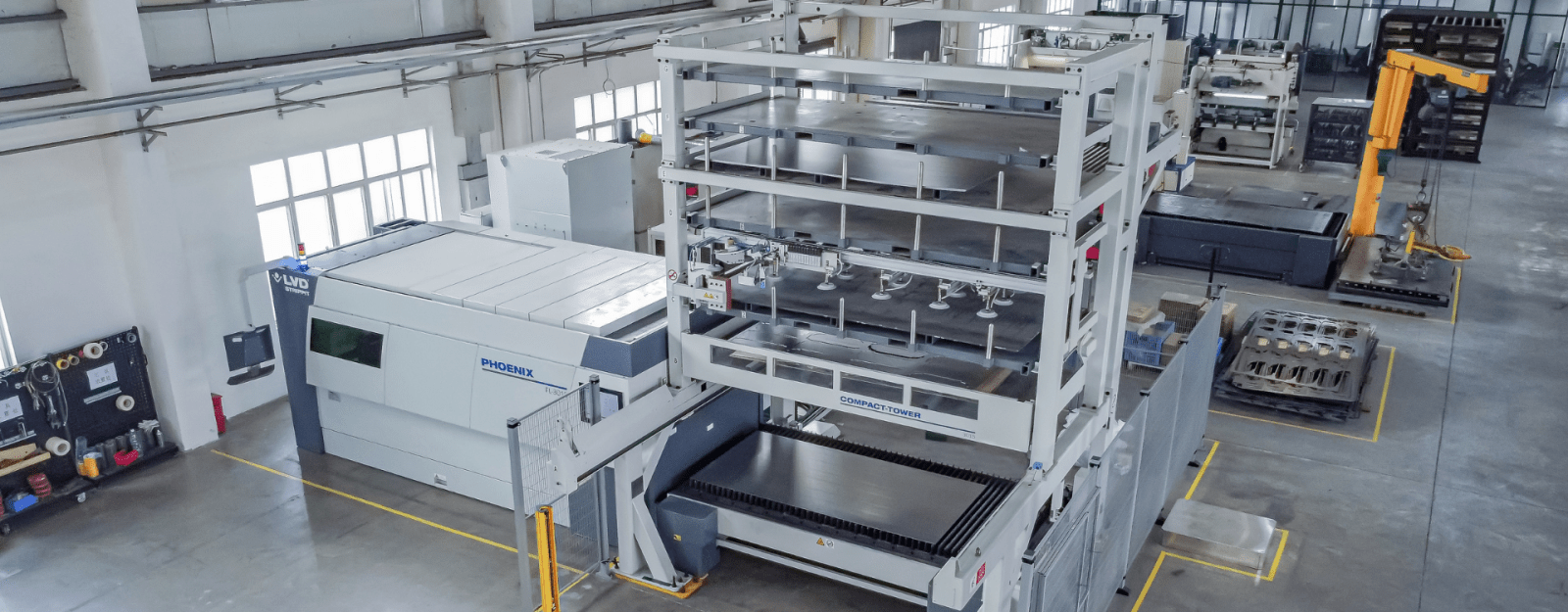

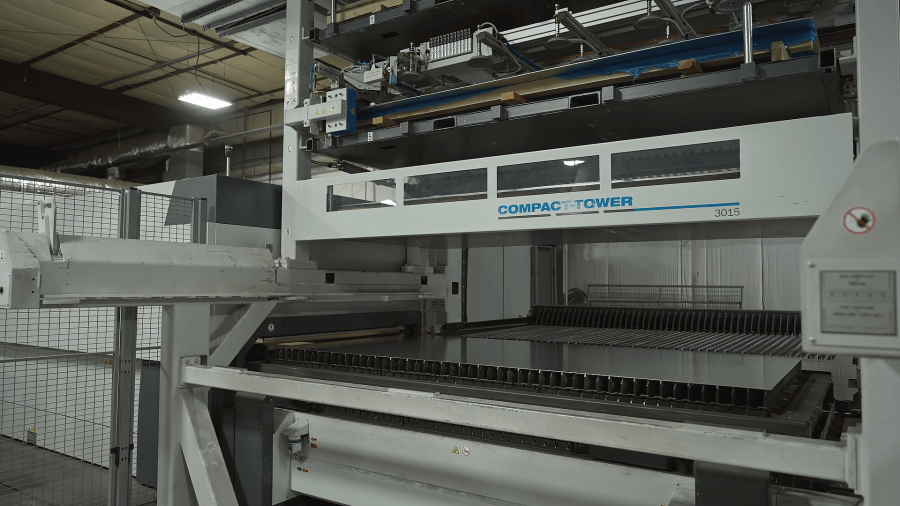

- Phoenix FL-3015 fiber laser with Compact Tower (CT-L)

- LVD software: CADMAN-B, CADMAN-L, CADMAN-SD

Website: www.komaspec.com