Strippit V-L

Strippit V-L provides the versatility of punching and laser technology combined for complete part processing. The thick-turret punch press offers large tooling capacity. Advanced fiber laser guarantees excellent cut quality at high cutting speeds.

- Thick-turret 30-ton punch press

- 4-kW laser source

- Sheet size format of 120" x 60"

- Smart factory - Industry 4.0 compatible

Highlights

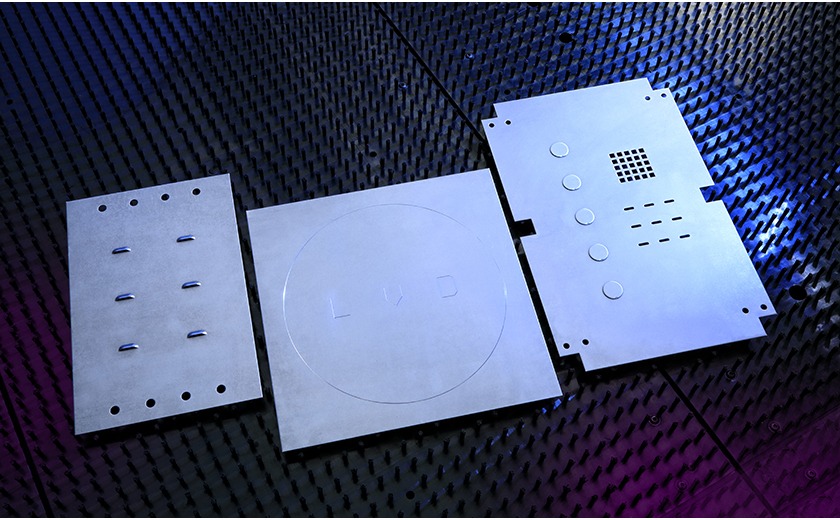

Thick-turret punch press

The Strippit V is a high-speed 30-ton hydraulic punch press built on a heavy-duty bridge frame for exceptional stability and punching accuracy.

High production capacity

The punch press features 48 thick-turret tooling stations with four 3.5" auto-index stations. This versatile mix of stations – able to accept forming, embossing, louvering, Wheel and tapping tools –maximizes tooling capacity and reduces set-up time for high production capacity.

Sleeved turret

Hardened turret sleeves ensure accurate punch and die alignment throughout the life of the machine. Sleeves can be easily replaced, eliminating the need for costly re-machining of the turret.

Smart ram control

Smart Stroke ram control automatically optimises the punch press ram motion for top productivity. No program codes or operator intervention required.

4-kW fiber laser

Laser cut unique shaped holes or contours and etch material with high-quality results using a 4-kW laser source.

Full-sheet processing

Cut and punch a full-size workpiece of 120" x 60" without repositioning to save on production time, material usage and material handling.

Large work chute for laser cut parts

A 15.9" x 60" work chute for laser cut parts makes it easy and convenient to evacuate processed parts or scrap.

Intuitive Touch-PL control

The latest LVD Touch interface is intuitive to use for operators of any skill level.

CADMAN-PL programming software

Integrated with the Touch-PL controller, CADMAN-PL makes programming and job set up for punching and laser cutting virtually automatic.

Technical data

| Maximum punching capacity | 30 metric tons |

| Maximum material thickness | 0.250" |

| Punching accuracy | +/- 0.004" |

| Repetitive accuracy | +/- 0.002" |

| 1 mm pitch | 910 HPM |

| 25.4 mm pitch | 440 HPM |

| Marking | 1750 HPM |

| Feed clearance | 0.984" |

| Nominal worksheet size | 120" x 60" |

*material thickness + tip recess + die penetration

| Brush table* | up to 330 lbs. |

| Combo ball/brush | - |

| Work chute | 15.9" x 60" |

| Work clamps | 3 CNC relocatable with part pull out sensor |

*at reduced speed

| Turret configuration | 48 stations - THICK |

| Auto-index stations | 4D – Ø 3.5" |

| Wheel Tool capacity | x |

| Tapping Tool capacity | x |

| Indexable Multi-Tool capacity | x |

| Angular positioning accuracy | ± 0.05 degrees |

| Controller | Touch PL |

| Combined positioning speed X-Y | 5039 in/min. |

| Tool change time | 0.9 - 2.1 sec. |

| Average power consumption | 23.7 kW |

| Standby operation | 0.9 kW |

| Automatic load/unload (PA) | x |

| Compact Tower (CT-P) | x |

| Flexible Automation (FA-P) | - |

| Bin sort | x |

| Robot pick/sort | x |

| Tower Automation System (TAS) | - |

| Warehouse Automation System (WAS) | - |

| Extended Tool Magazine (ETM) | - |

| Lubrication system | x |

Specifications subject to change without prior notice.

Options

Modular automation systems

An automation system further extends machine efficiency and process reliability. Choose from a range of options, including Compact Autoload, Bin-sort System, Compact Tower (CT-P) for material storage and retrieval, full Tower Automation (TAS) or Warehouse Automation (WAS). A robotic interface can also be integrated.