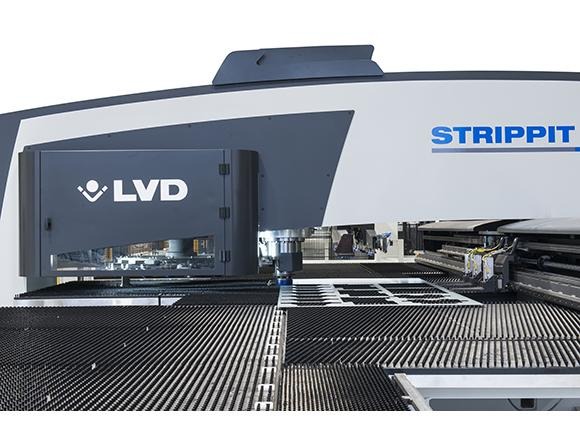

With an exceptionally long X-axis, the Strippit V30 1550 is the only punching machine of its kind engineered to allow the processing of worksheets up to 5000mm long by 1500mm wide without multiple sheet repositions, excessive sheet handling or extra shearing operations. By reducing non-value part handling time, punching and forming operations are more productive and cost efficient. The ability to process a large sheet size also reduces welding and other secondary tasks, decreasing the cost per part.

EXTRA-LONG X-AXIS

A rack and pinion design delivers precise motion and rigidity over the full length of the 5-meter axis. The X-axis traverse speed is efficient at 3150 IPM (80 m/min) with a combined axis traverse speed of 4095 IPM (104 m/min). The Strippit V30 1550 has a maximum hit rate of 440 hits per minute on 25,4mm centers in material thicknesses up to 6,35 mm.

HEAVY SHEET-CARRYING CAPACITY

The machine’s advanced positioning system provides the industry’s heaviest sheet carrying capacity at full speed. The advanced table positioning system of the Strippit V30 1550 produces a finished part accuracy of 0.1 mm with a repeatability of +/- 0.05 mm over the entire table travel. The accuracy of finished parts provides process stability.

PRODUCTIVITY-ENHANCING FEATURES

The Strippit V30 1550 is designed for continuous, productive punching and forming, featuring:

- Versatile 48-station thick-style turret. The turret’s hardened steel guide bushings ensure accurate punch and die alignment and are keyed to accept shapes in every station. Bushings can be quickly and easily replaced by the operator, avoiding costly re-machining of the turret. A thin-turret option is also available.

- Four programmable work clamps. Work clamps can be individually programmed on the X carriage and relocated to a new position within the part program to maximize sheet usage. As one clamp is moved, the others hold the sheet firmly in place.

- Large 450 x 500 mm work chute for part removal.

- LVD’s latest-generation Touch-P control.

- All brush or combination brush/ball table, depending on application requirements.

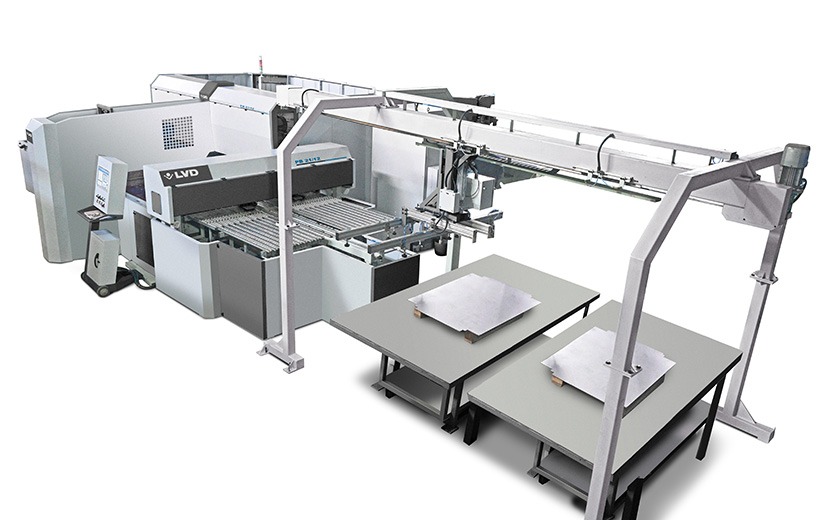

- Optional 4-meter auto load/unload system.

REPLACES PUNCH-SHEAR COMBINATION

The first installation of the Strippit V30 1550 has been completed for a fabricator specializing in perforated metal solutions for industries ranging from aerospace to architecture. In this application, the Strippit V30 1550 replaces a punching machine integrated with right-angle shear able to process worksheets up to 1575 by 4025 mm.