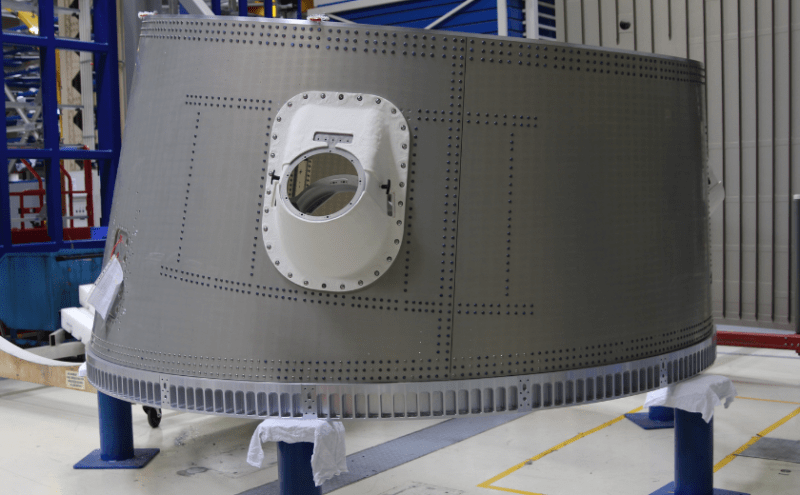

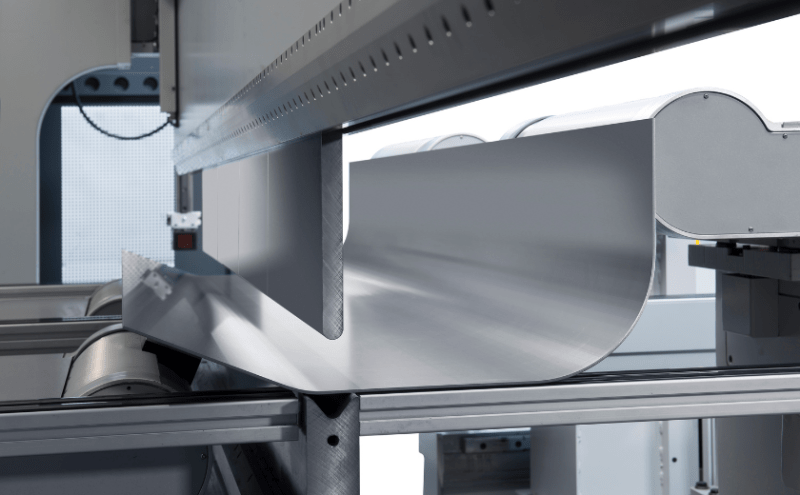

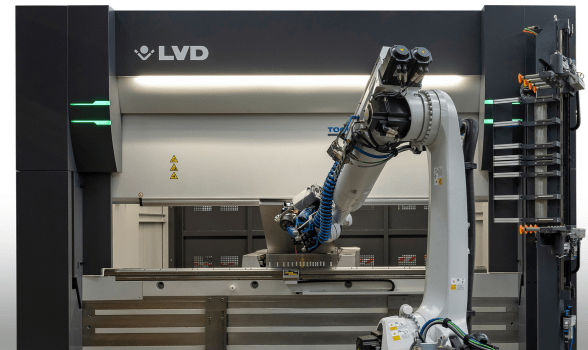

LVD Company nv, one of the world’s leading suppliers of heavy-duty press brakes, has won a major contract to manufacture a custom Synchro-Form press brake for MT Aerospace AG, Augsburg, Germany, a subsidiary of the space and technology group OHB SE. A state-of-the-art heavy bending machine, the Synchro-Form 800-ton, 7-meter press brake will produce critical structural components for the European Space Agency (ESA) Ariane 6 space rocket program, an initiative aimed to enhance Europe’s position in the global space market.

The order reinforces LVD’s reputation as a trusted supplier of advanced, high-performance bending equipment and heavy-duty press brakes tailored to meet demanding operational requirements.

“This contract represents a strong endorsement of LVD’s bending expertise,” said Carl Dewulf, CEO of LVD Group. “It reflects the confidence placed in our engineering expertise and proven history in meeting challenging forming applications.”