Ladbrook Manufacturing was established back in 1936 down in London by the Spinks family. When it was first established, it was set up for press work. High volume down to low volume, but it was all done through metal pressing. About fifteen years ago, we started looking into getting into sheet metal. The company made the decision to purchase two new machines.

They were second-hand: a Shape Delta punch press and a PromyCam folding machine. That was what originally got us into sheet metal. In 2017 a decision was made to start looking for a new machine because the Shape Delta was heading towards 25 years and parts and servicing were becoming harder.

It wasn't really feasible to move forward with it. The first LVD machine we bought was a punch press, it was a P1225 with a 2.5 by 12.50 table size that could extend to over 4 metres, which allowed us to go from running 1 metre by 1 metre sheets up to larger 2.5 by 1.25 sheets. From 2018, things went from strength to strength with the sheet metal side of the business.

Then in 2022 it came to a point where the punch press and folding were at full capacity and we needed to start looking at how we could invest further, not just to keep up with the modern-day trends but also to look at winning new work and increasing day to day capacity.

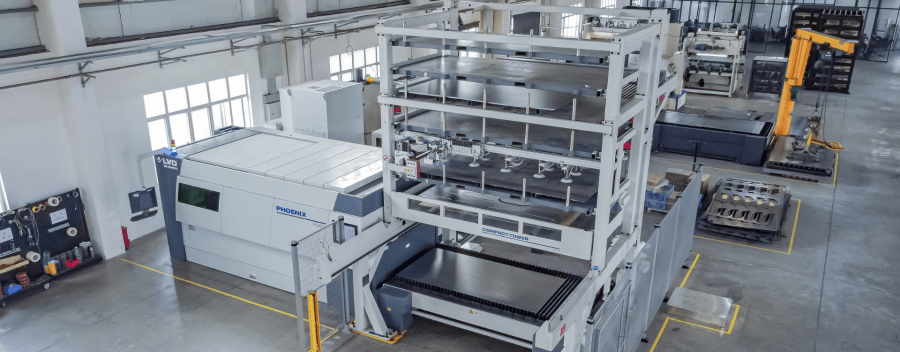

We decided to go for a Laser ONE, as well as the Easy-Form and Dyna-Press at the same time. The size of the investment for us as a company was massive. It's the biggest single investment we've looked at in the history of the company. The new two press brakes and the laser have doubled our capacity, whereas before we had everything on the punch and if there was anything with a tight radius, we would struggle to punch it or we'd have to do multiple hits to get the radius we needed. Now we can just go around with the laser so it improves efficiency.

Part of the investment with the three machines was the implementation of CADMAN because it just integrated three or four machines. We could take a part, we could cut on the laser and it'd naturally go into CADMAN for the press brakes and folding. It just seemed like the logical thing to do.

CADMAN's been brilliant for us. You can now take a drawing, import it and take it through the whole process. Before we'd have to take an estimate or run a trial whereas now it does everything for you.

One thing we really liked about the LVD machines with the CADMAN was how similar all the machines were from an operating point of view. So all the interactions, the touch screens and the programming were all very similar. The guys were really impressed with how easy and quick it was to use. They are really pleased with the system they use. The biggest thing with the investment we made was the relationship with LVD. We've always had a really good relationship. Their quality and service has been second to none and that has been one of the major driving points for investing so heavily down one company's line of machines and software.