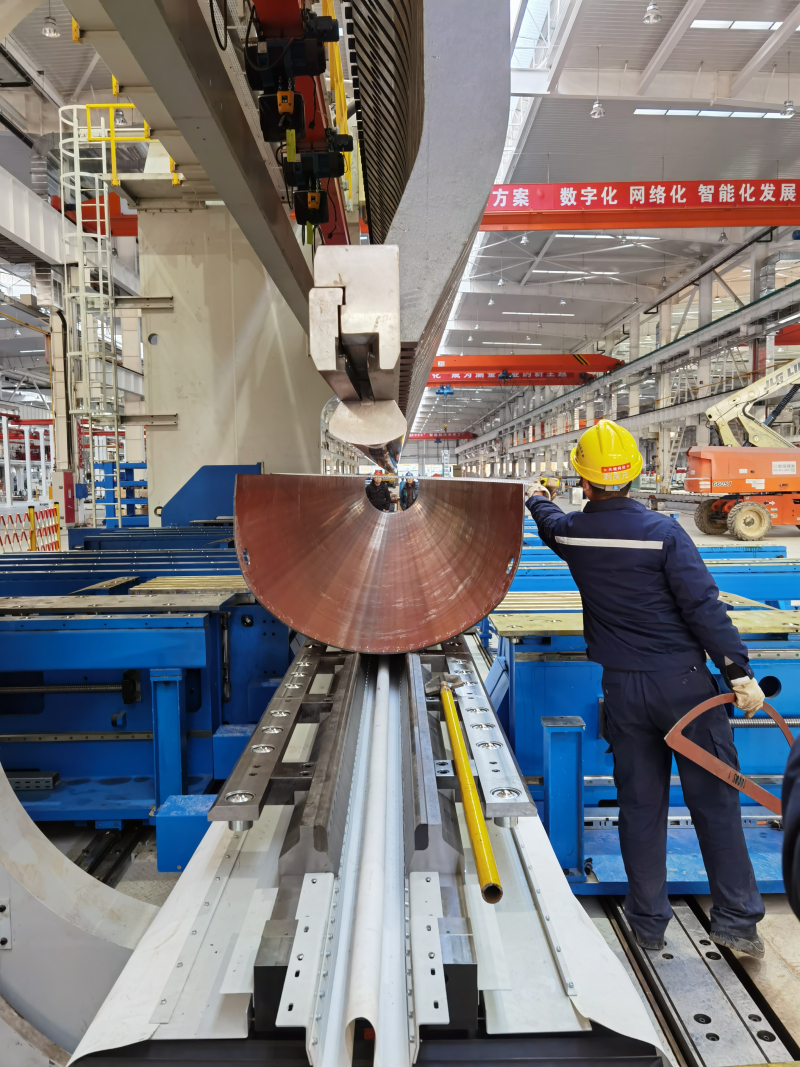

“For the stability of the machines, which individually weigh 450 to 650 tons, foundation work was required. Five-meter-deep wells were made in advance, on which the various parts were placed one by one, under supervision of LVD-HD.

“The complete project, from production of the parts and transport to installation and startup took only one year. Since April, the press brakes are fully operational,” says Mr Wei.

The machines were co-manufactured by LVD Company and the Chinese joint venture LVD-HD. LVD Company made the precision parts in Slovakia and Belgium, including cylinders, adjustable V-die, crowning table and complete control box. Integration of these components was monitored on site by LVD personnel. LVD-HD was responsible for frame construction, assembly of the machines and commissioning. The company gave the operators the necessary training and will continue to provide service as it already does for the other LVD machines.

“We have been satisfied with this good cooperation for years and still have a lot of plans for the future!”