How many 'foreign' operations can I add into the process flow in CADMAN-JOB?

The actual number is unlimited but the type of operation is somewhat limited. We limit the type of operations to those that happen just after laser cutting, or we start from a blank, and just before or just after bending. Classic examples are chamfering, tapping, painting and packaging parts.

Where we draw the line is assembly. Bringing multiple parts together is not our expertise, so welding parts or assembling parts is something we don't tackle.

But the actual number of foreign operations is completely unlimited. While carrying out the installation we get together with the customer to see what operations he wants to include and then we generate them in the factory.

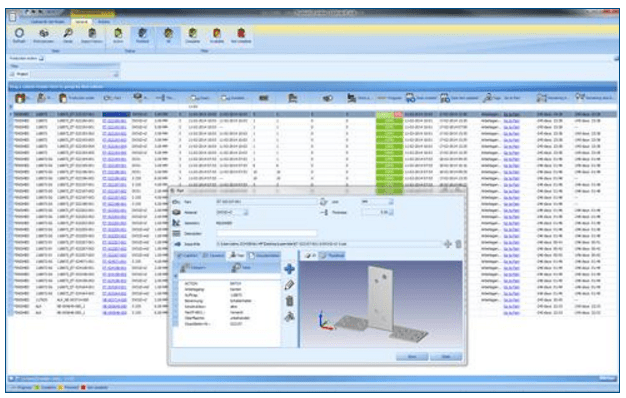

CADMAN-JOB serves as central production control to improve a workshop’s overall process flow. It connects the front office and shop floor to manage jobs for increased throughput, minimized set ups and streamlined work flow, providing real-time visibility and full transparency of the sheet metal fabrication process.