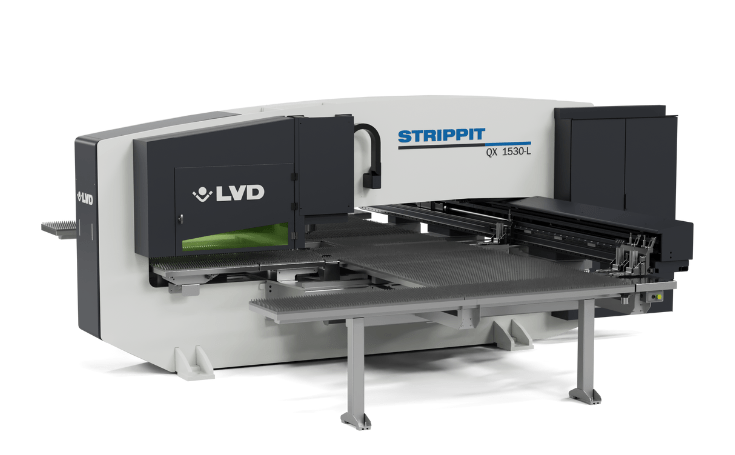

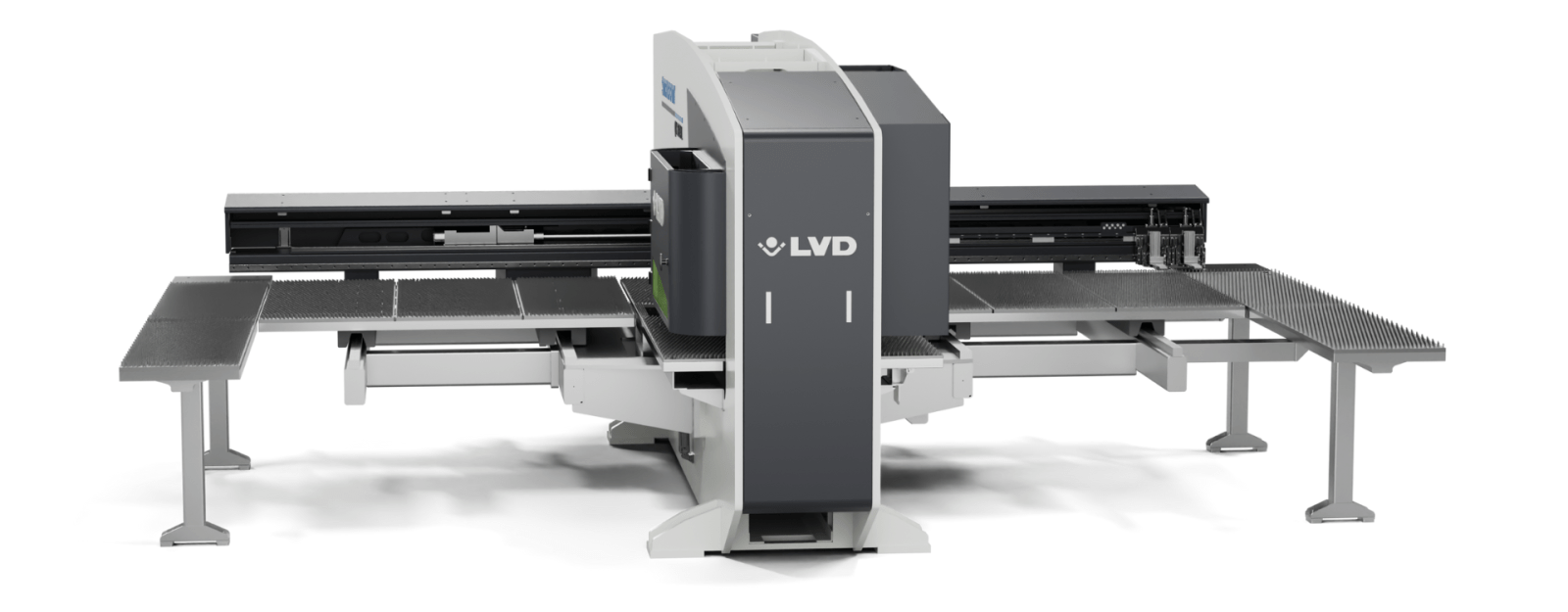

LVD Company nv introduces the Strippit QX-L, a mid-range punch-laser combination machine that delivers strong value through integrated punching, forming, and laser cutting capabilities. It combines a single-head Strippit punch press with a 4-kW fiber laser to perform multiple fabrication processes in one system for streamlined production workflows. Strippit pioneered punch-laser combination technology in 1978 and has 100 years of punching expertise. Strippit QX-L reflects this legacy, delivering a smart alternative for flexible part processing.

“While combination machines offer an all-in-one solution, their cost of ownership is typically higher due to the dual technologies,” says Pierre Comhaire, LVD’s punch press product sales manager. “With the Strippit QX-L, we’ve made the punch-laser more affordable and accessible for more fabricators.”

OPTIMIZED TECHNOLOGIES

Strippit QX-L delivers the advantages of punching and laser cutting technologies in an optimal way, balancing machine features and cost. It punches materials up to 3 mm, produces bends up to 75 mm, and laser cuts metals and non-metals up to 3 mm.

The machine can manage a full 3000 x 1500 mm sheet, which optimizes sheet utilization, reducing production costs and manual handling.

The laser cutting head is a fixed design. It automatically adjusts the focal point to the desired position and beam diameter for the best possible cutting results. Cutting gas selection and pressure control are automatic.

Every tool in the 20-ton punch press is auto-indexable a full 360 degrees, minimizing setup and tool change time. The machine holds tools up to 90 mm in diameter. Louvers, tabs, coining, embosses, knockouts and flanges, as well as high forms on complex geometries, can be produced, reducing or eliminating secondary operations.

Programmable work clamps can be automatically repositioned during the punching cycle, no need for manual adjustment between jobs or even during a single sheet run. Strippit’s Smart Clamp technology makes 100 percent sheet utilization possible with no worksheet dead zones.

Strippit QX-L is equipped with a 474 x 525 mm programmable part chute for offloading punched parts; a 292 x 525 mm parts chute for laser cut parts is optional. Automation options include a L/U system or compact tower for loading, unloading and storage of raw materials.

A TOOL FOR TODAY

Today’s fabricators face increasing pressure to handle smaller batch sizes, faster turnaround times, a broader range of products, and more complex part designs. In this environment, machine versatility is more important than ever.

Strippit QX-L addresses these challenges by enabling the complete processing of parts in a single setup. This results in improved throughput and lower per-part manufacturing costs.