Strippit E

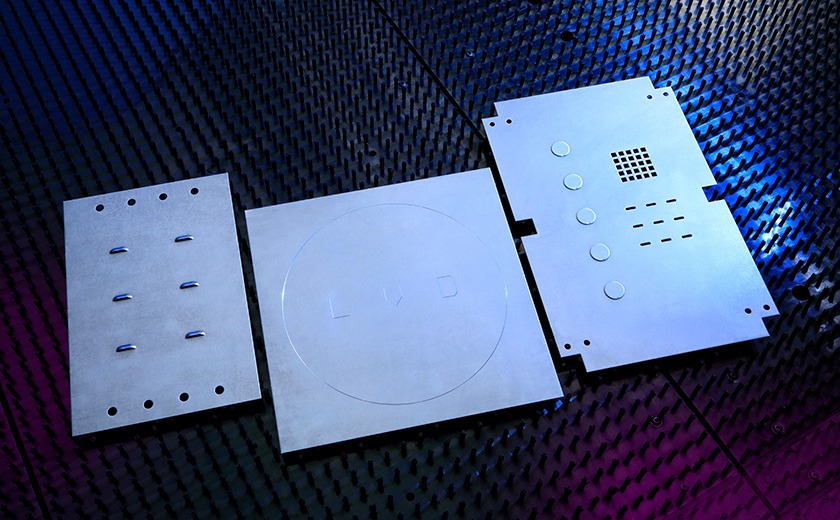

Strippit E is an energy-efficient servo-electric drive punch press. Precise control over the ram provides exceptional repeatable accuracy for punching and forming. The streamlined design uses fewer mechanical components, keeping machine reliability and uptime high.

- 47-station turret

- 0.984" feed clearance for forming

- 49.2" x 98.4" and 60" x 120" formats

- Smart factory - Industry 4.0 compatible

Highlights

Advanced servo-electric press drive

The servo-electric press drive is energy efficient – at least 20% more efficient than hydraulic designs – and economical to operate with a power requirement of just 20 kVA. It uses a minimum number of components for highly reliable operation, reduced maintenance requirements.

47-station turret

A large 47-station turret features three 3.5" auto-indexable stations for tremendous tool-carrying capacity and flexibility.

Enhanced forming

Precise control over the ram delivers consistently accurate results for knockouts, wheel tool and forming operations, including countersinking and stamping. Ram positioning can be held to ± 0.001. A 0.984" feed clearance offers more forming capacity.

Heavy-duty frame

Engineered for superior accuracy and long production life, the Strippit E machine is built on a heavy-duty, closed-welded, stress-relieved frame for maximum stability.

Easy setup and changeover

The Strippit E offers the easiest tool changeover in the industry. Quick-change die holders reduce setup time.

CNC relocatable work clamps

Automating work clamp movement reduces setup time and increases productivity. Three CNC relocatable work clamps with sheet pull out sensors are standard on the Strippit E-1530, available as an option for the Strippit E-1225.

Smart Clamp

Smart Clamp automatically detects exact clamp locations to provide the smallest possible no-punch zones.

LVD Touch-P control

An easy-to-use, icon-driven touch screen control simplifies machine operation.

CADMAN® software suite

A full suite of software modules create a fully integrated process flow, including CADMAN-P punching programming software, CADMAN-SDI drawing importer, CADMAN-JOB real-time data collection, job tracking and ERP connection, as well as a Touch-i4 tablet for KPI performance indication and sorting and validating parts.

Technical data

| E-1225 | E-1530 | |

| Max. punching capacity | 20 metric tons | 20 metric tons |

| Max. material thickness | 0.250" | 0.250" |

| Punching accuracy | ± 0.004" | ± 0.004" |

| Repetitive accuracy | ± 0.002" | ± 0.002" |

| E-1225 | E-1530 | |

| 1 mm pitch | 500 HPM | 500 HPM |

| 25.4 mm pitch | 350 HPM | 350 HPM |

| Feed clearance | 0.984" | 0.984" |

| Nominal worksheet size | 49.2" x 98.4" | 60" x 120" |

*material thickness + tip recess + die penetration

| E-1225 | E-1530 | |

| Brush table* | up to 364 lbs. | up to 364 lbs. |

| Work clamp | 2 manual (optional 3rd clamp) | 3 programmable CNC clamps |

| (optional 3 programmable CNC clamps) |

*at reduced speed

| E-1225 | E-1530 | |

| Turret configuration | 47 stations | 47 stations |

| Auto-index stations | 3D - Ø 3.5" | 3D - Ø 3.5" |

| Wheel Tool capacity | x | x |

| Tapping Tool capacity | x | x |

| Indexable Multi-Tool capacity | x | x |

| Angular positioning accuracy | ± 0.05 degrees | ± 0.05 degrees |

| Controller | Touch-P | Touch-P |

| Combined travel speed X-Y | 128 m/min. | 110 m/min |

| Tool change time | 0.9 sec. | 0.9 sec. |

| E-1225 | E-1530 | |

| Average power consumption | 5.5 kW | 5.5 kW |

| Standby operation | 0.9 kW | 0.9 kW |

| E-1225 | E-1530 | |

| Automatic load/unload (PA) | x | x |

| Compact Tower (CT-P) | x | x |

| Flexible Automation (FA-P) | - | - |

| Bin sort | - | - |

| Robot pick/sort | x | x |

| Tower Automation System (TAS) | - | - |

| Warehouse Automation System (WAS) | - | - |

| Extended Tool Magazine (ETM) | - | - |

Specifications subject to change without prior notice.

Options

Additional clamping

The Strippit E-1225 features two manual work clamps and is available with an optional third work clamp or optional three CNC relocatable work clamps with part pull out sensor.

ABS automatic tool lubrication system

Air blow system automatically lubricates the punch and guide to help ensure efficient tool stripping and extend the time between regrinding.

MOVit automation

A modular automation system further extends machine efficiency and process reliability. Choose a simple Compact Autoload, Compact Tower (CT-P) for material storage and retrieval, or full Tower Automation (TAS) or Warehouse Automation (WAS) systems.