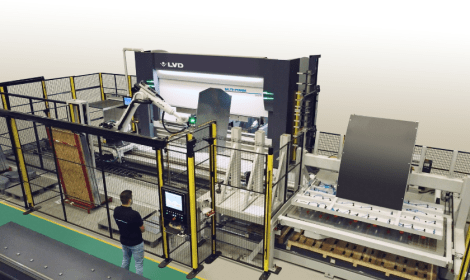

Robotic bending systems

With Robotic Bending Systems (RBS), LVD moves from standard bending cells to flexible, modular bending systems. In five steps, you can configure a bending solution that perfectly matches your parts, volumes, and automation goals.

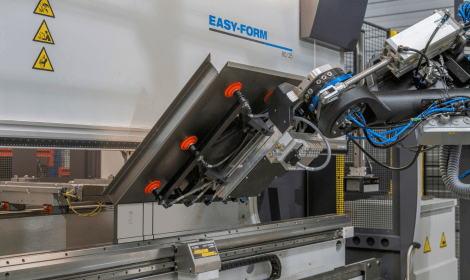

Standard solutions such as Dyna-Cell, Easy-Cell and Ulti-Form are now fully integrated into RBS. While the product names disappear, their configurations remain available, enhanced with more possibilities than ever before.