EXPANDING ROBOTIC SOLUTIONS

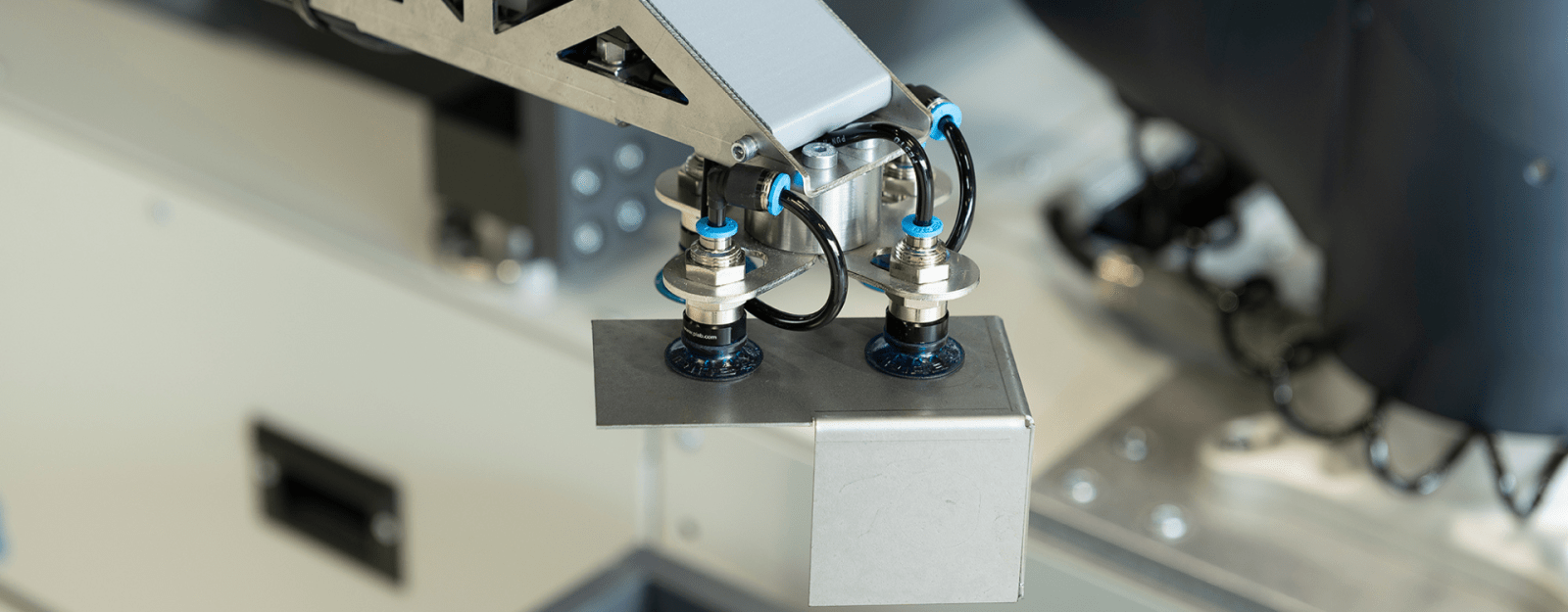

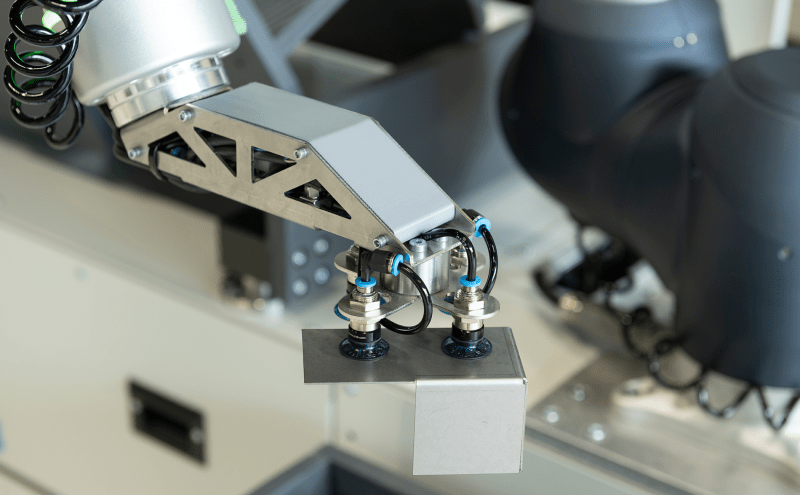

LVD Robotic Solutions (LRS) was established in 2022 following the acquisition of KUKA Solutions Benelux. Its goal is to make robotic automation more accessible and affordable for manufacturers. LRS develops customized solutions for a wide range of industries and applications - from turn-key handling systems to machine tending and material flow optimization.