And then overall throughout the years, if we have bearings go out and different things like that, we're able to address those very quickly and keep the machine running. One of the nice things with LVD controls is through the years, the main controls stay the same. So as we're training operators, we can have them go from machine to machine, different year machines.

And they get the same buttons to pull up programs to make adjustments. The operation on that control side is very easy to use. It's very easy to make adjustments as you're forming on the fly. There's not a lot of back screens you have to go into for training. You can train mainly off one screen. CADMAN B really gave us the ability to unfold parts and be successful without a lot of setup parts.

In our business, we have to look at how we can be competitive. One of the areas that we shine in is if a customer orders 100 parts, we cut 100 parts, we form 100 parts and we ship 100 parts. So it took a lot of setup time out. Since we've adopted the CADMAN in our shop here, our setup times have gone down significantly.

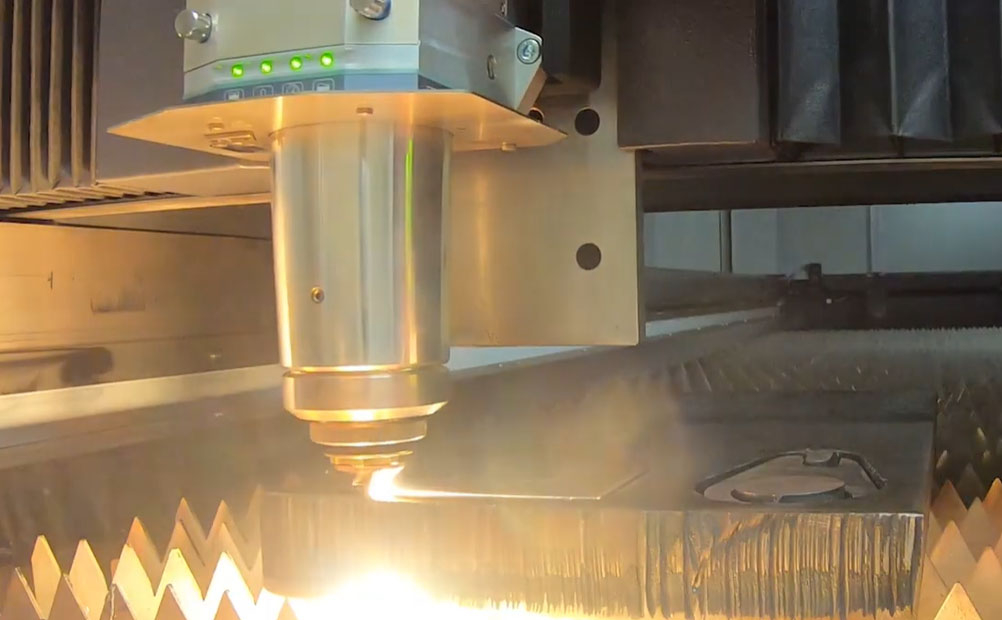

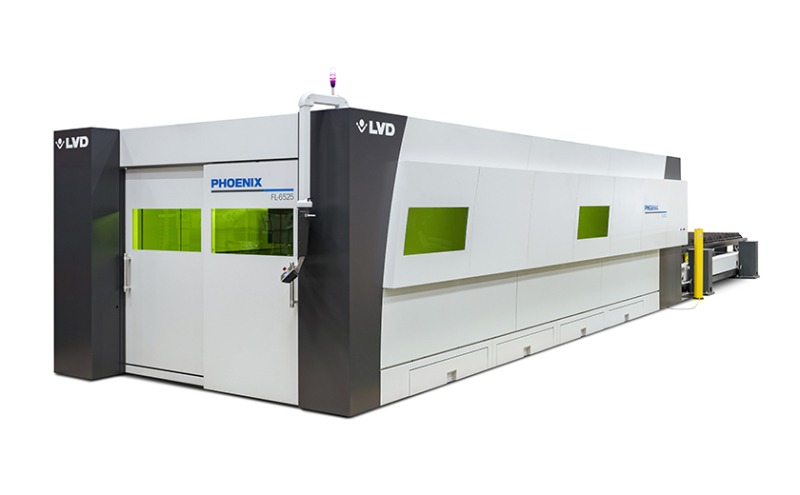

One of the interesting things here at Last Arrow is we're producing over a million pounds of aluminium per year. We're producing right now about 350,000 pounds of metal per week through our lasers and through our brake presses. LVD does a great job of getting in here, getting the machine up and running and producing for us on the brake presses.

We're talking just a matter of less than a day to get that machine set up and running and producing parts for us. This last Phoenix laser, it was a very, very good successful install for us. Out of all the lasers that we bought in the last 12 years, this machine has been the fastest to hit our floor and get operational and start producing parts.

The DynaPresses have really surprised me with their ability of parts that we can form on them. Originally we were thinking they were going to do small parts. Right now we're utilising up to the full bed space on them. We're doing a wide mix of parts from very complex bending, high tolerance parts to very large parts.

They've increased our capacity to put more parts through with less of a footprint.