The background of the company is it was formed 55 years ago by my dad, literally in the back garden shed. We've evolved and grown ever since then and have gone through different evolutions of manufacturing.

We are a family business. All the directors are members of the family. I started here 37 years ago as an apprentice. Then Darren joined the company two years later. We're very passionate about what we do and how we look after our staff and our customers.

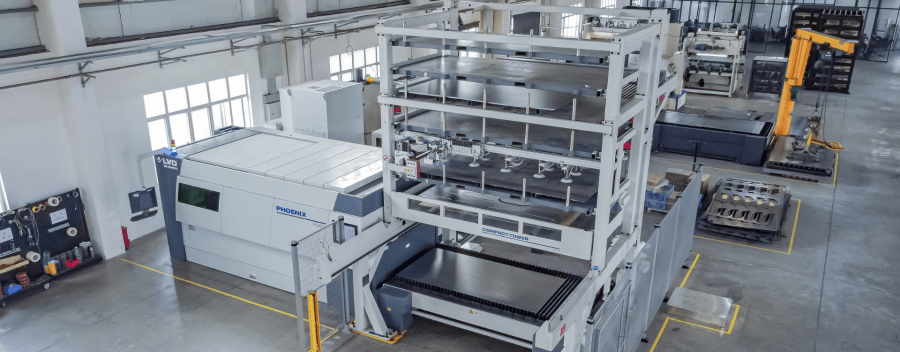

We're about a team as well, in that we are all working together. We regularly hold meetings with our staff to get good and bad feedback as well. How we can progress production planning for the day, because it changes so fast these days. That's why we've evolved with LVD's help to ensure that we can produce things quicker and faster to cope with the demands that are placed on us as a company. I think the LVD equipment has helped us develop thanks to the constant research and development to improve the machines that we buy from them. They continue to evolve through firmware, software upgrades to improve the features, the abilities of the machine. The laser is a case in point: it evolved and from what we bought as a machine three and a half years ago, the capacity's increased because of the development that LVD have put into that machine with their technology. Likewise with the ToolCell. We saw this four years ago and it was something that stayed with us for a long time, thinking that was the natural evolution.

Set-up times are greatly reduced. Basically it's running from laser punching to folding that enables us to produce things a lot faster than many years ago.

We can train people to run these machines and if you're running the ToolCell then you can move on to the PPEB and you can move back down to the Dyna-Press and the interface is the same. So in theory, if you learn one, it's very easy to adapt to either machine. They've got more features but Darren and I love the way that they're all user-friendly.

We work very closely with both LVD UK and Belgium. To use a phrase that LVD has, it's ‘from art to part’. It's the way that we like to work and that is that the investment in the software and the machinery enables us to make 5 or 10 or 10,000. We can reduce our scrap rate by being more efficient in utilising the machinery and the software. And that's why we work closely with LVD.