My name is Nigel Bamford from Escea Gas Fireplaces. We are located in Dunedin, a city down the bottom of New Zealand. We manufacture a range of gas fireplaces and everything we do is therefore in quite thin metals, 0.9 to 1.6 gauge mostly. We've got a lot of parts. We've got fourteen different models, each of which has several hundred parts. We make around three and a half thousand different parts and not always in large volumes, so we needed to find the best sheet metal working machine money could buy.

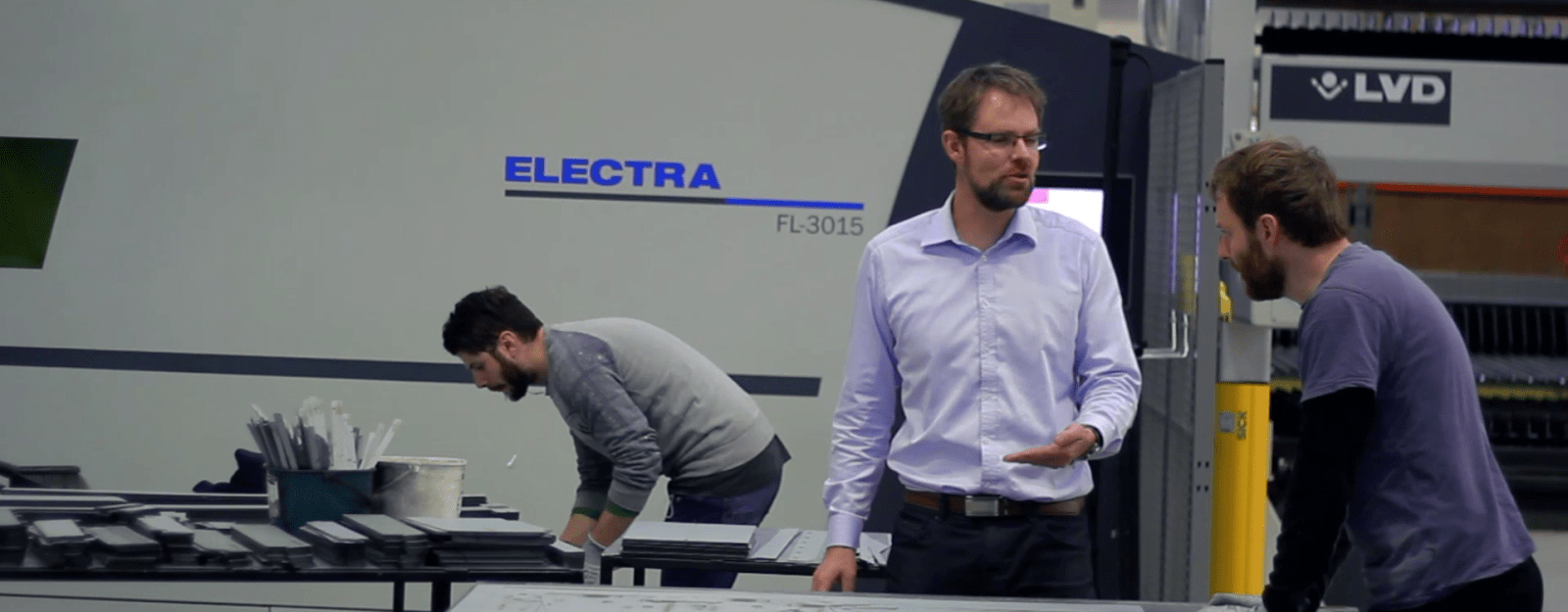

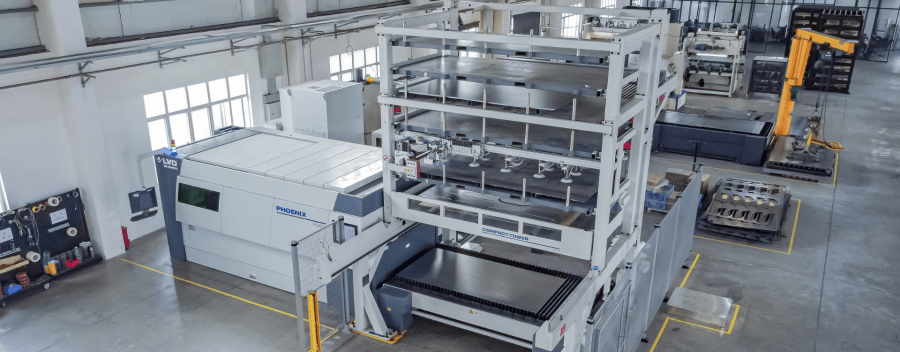

What really mattered to us was speed and accuracy and we also wanted some really good after sales service because we understand that here in Dunedin we are about as far away from Europe as you can get. So we needed to choose a company that could both provide us with great machines but also look after us after that event. We chose the Electra 3-kilowatt fibre laser from LVD. It's proven to be a really good choice for us. It's extremely fast. We also chose the tin shelf material tower. That's obviously let us have lots of materials stored up.

The machine grabs the material – quite often it needs just one sheet of each material - and then we store all the finished parts up in the tower as well. Then we have our breakout table and a few times a day, we get some people on the breakout table pulling the parts off. In a normal production run at normal speed, we're using our LVD laser for about 16 hours a day. Two shifts, five days a week. But when we get really busy, we also run around the clock. We run the last shift with lights out. We also bend all of our own parts here. And we'd like to work on a little-and-often approach to bending so we don't do very large runs. So we need press brakes that are fast to operate, fast to set up and most of the time we're pulling up the same program each time.

We decided it was too slow to use our large hydraulic press brakes to bend our small parts so our latest purchase is an LVD Dyna-Press. The guys really love using this machine. We now bend our smallest parts on this small, fast press brake and we leave the larger parts to our larger press brakes. This approach has really sped up our total overall bending speed significantly.

We've enjoyed dealing with LVD. We've found them being really responsive during both the sales process and also with after sales service. We worked through their agents, GWB of Australia, who have also been great to deal with, and I couldn't recommend them better.