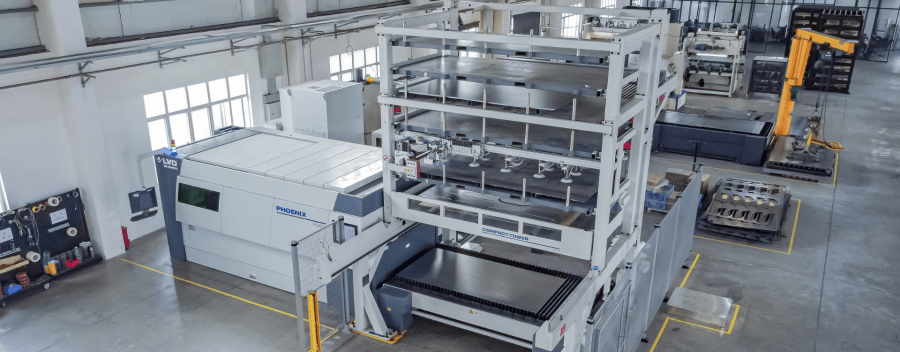

In addition to the Phoenix fibre laser, which is a more standard system, the automated material tower is custom configured for our hall height so that we have additional storage space for sheet metal. We have a clearing trolley that moves in two directions, which was also a special feature we requested.

As for the software connection, we thought a long time about how to implement it. Ultimately we decided not to use LVD software in order to be open to other technology in the future, a decision that LVD understood. We use WiCAM, manufacturer-independent software, which optimally supports the machines and is also futureproof. The open software interface, in which we were very interested, is in our opinion the only thing that competes with LVD, which speaks for LVD because the same cannot be said of other providers.

LVD is a company driven by a corporate culture that is similar to ours. It is a family business, which is reflected throughout the company. That prompted us to partner with LVD.