LVD LAUNCHES NEW EASY-CELL BENDING AUTOMATION

LVD showcases a new robotic bending cell – a highly flexible bending automation solution for the widest possible range of parts – along with electric-drive Dyna-Press Pro press brake and new CADMAN®-Flow software at TechniShow, Hall 7 – Stand D056. LVD press brakes and bending cells, powered by its fully re-engineered benchmark bending software, make bending easier, more precise, and productive to benefit job shops and OEMs alike.

FLEXIBLE SCOPE

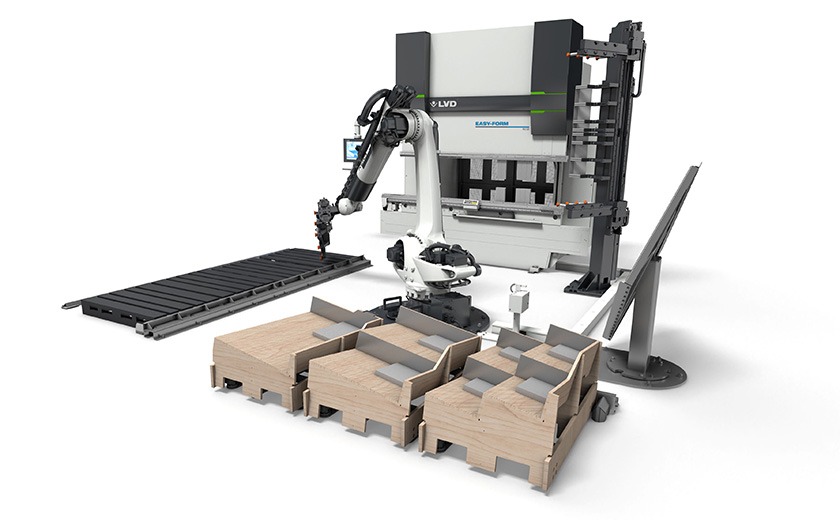

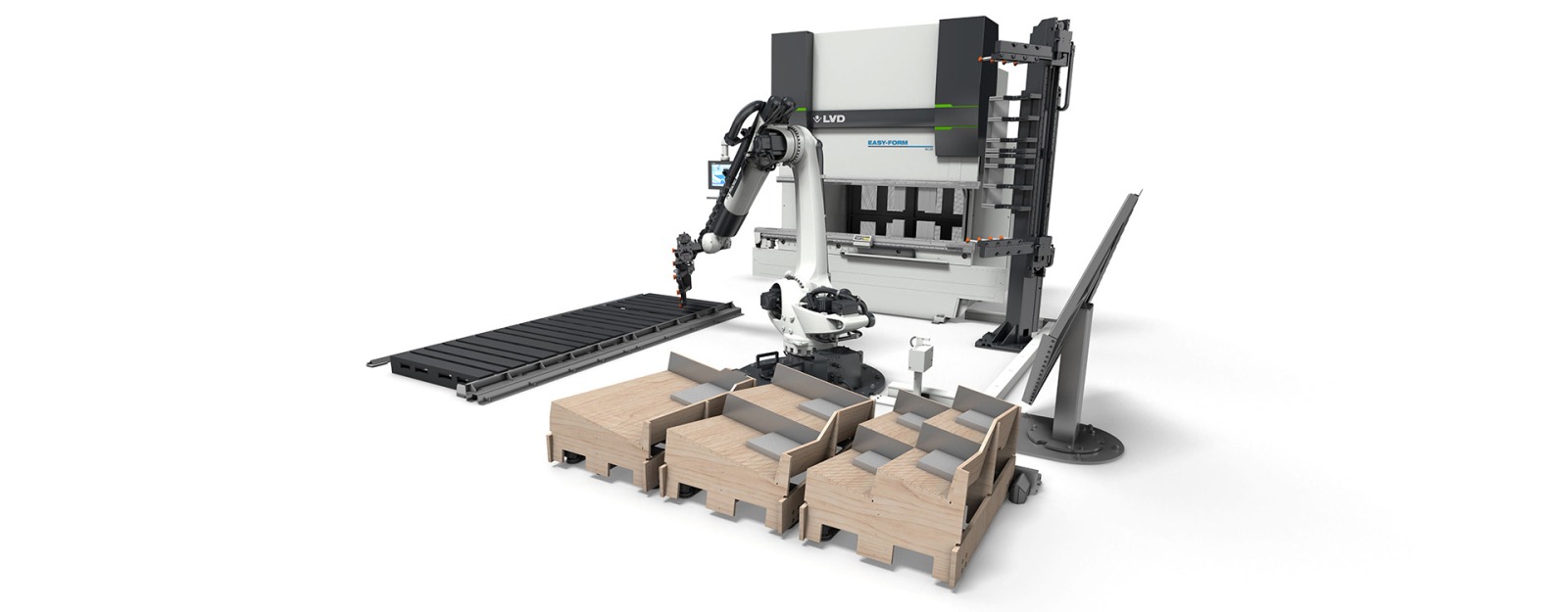

The new Easy-Cell 80/25 combines an Easy-Form 80-ton press brake with Kuka industrial robot to handle parts from 100 x 100 mm up to 1600 x 1200 mm weighing up to 25 kg. The press brake features a 2500 mm bend length, five-axis backgauge, and 2500 mm crowning table, providing the versatility to accommodate a broad scope of bending applications. Easy-Cell offers high flexibility to produce a wide range of parts with the precision of a built-in adaptive bending system which ensures bend angle accuracy from the first part. LVD CADMAN software ensures fast, simple offline programming of both press brake and robot.

PRECISE PART PRODUCTION

The Dyna-Press Pro at TechniShow will demonstrate LVD’s Easy-Form® Laser, an optional feature of the machine. The adaptive bending system provides repeatable bending accuracy assured from the first bend. Easy-Form Laser transmits data in real time to the CNC control, which processes the information and immediately adjusts the position of the punch to achieve the correct angle, automatically compensating for material variations such as sheet thickness, strain hardening and grain direction. The bending process is not interrupted and no production time is lost.