Booth Dispensers was formed in 1965 and manufactures refrigeration equipment, initially for the soft drinks industry but more recently we’ve diversified to manufacturing equipment for the brewery industries, both in the UK and worldwide.

The main reason for purchasing the PX machine was the fact that our volumes were increasing because our customers were getting very busy. It was a case of needing something quickly to be able to fit that process. We currently use 46 tools in the head, so this allowed us to produce all our old products while giving us capacity to add new products going forward as well.

We have two LVD press brakes in the department, both of which were bought in the last five years. The reason we went for one to start with was simply a desire to increase our capacity. However, we found that the speed of that machine and the ease of operation gave us more than we bargained for and in the next four years, we invested in another machine as well.

The Touch-B system, we found, is easy for the operators to use. It’s easy for them to change over from small batches, large batches, and it's very quick for the process so there's very little downtime between jobs.

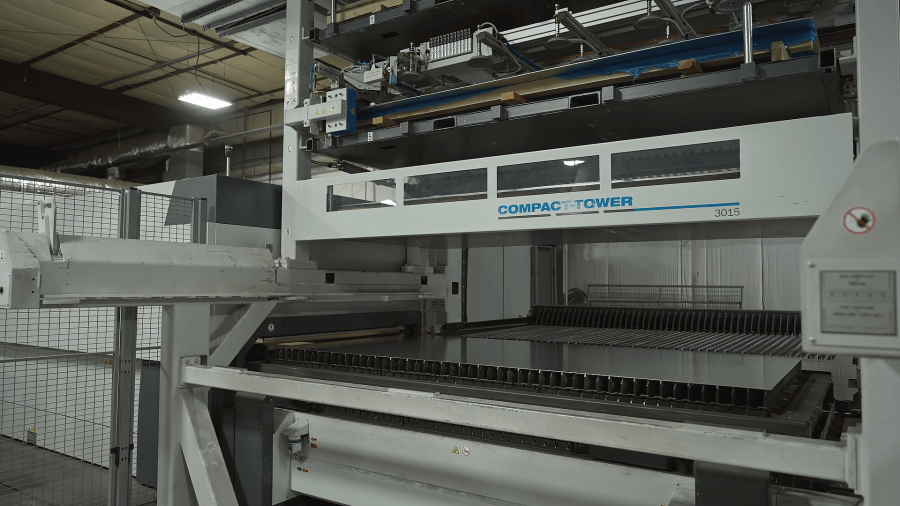

We are currently looking into expanding our range with LVD, including the CADMAN product and some laser products. Aspects of the CADMAN software that will benefit us include increased efficiency, increased control within the business and higher product quality for our customers.

Our relationship with the LVD service department is, I would say, excellent. Whenever we have any issues, when we have a machine breakdown, we can always ring up straight away and we will generally get an engineer here on site within a day. And then we're up and running again.

We've been working with LVD since 1999 and since then we have expanded our product range with them, increasing our efficiency, increasing the quality of our products and we look forward to building the relationship further in the future.