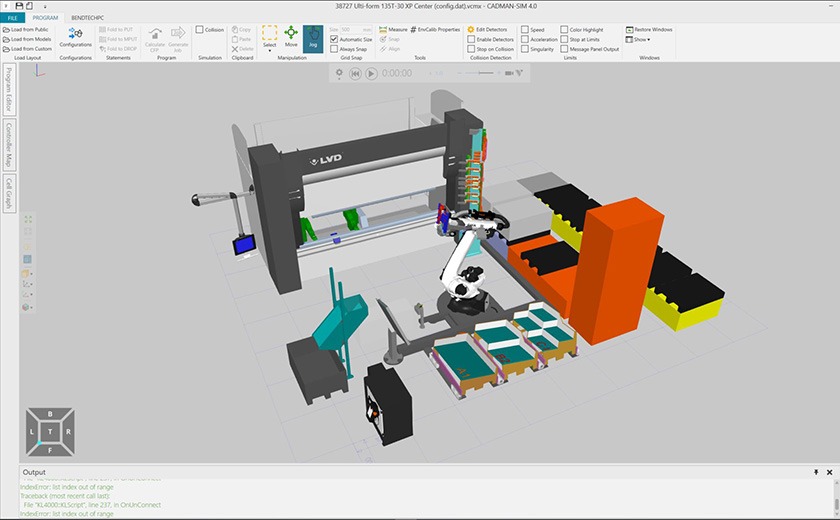

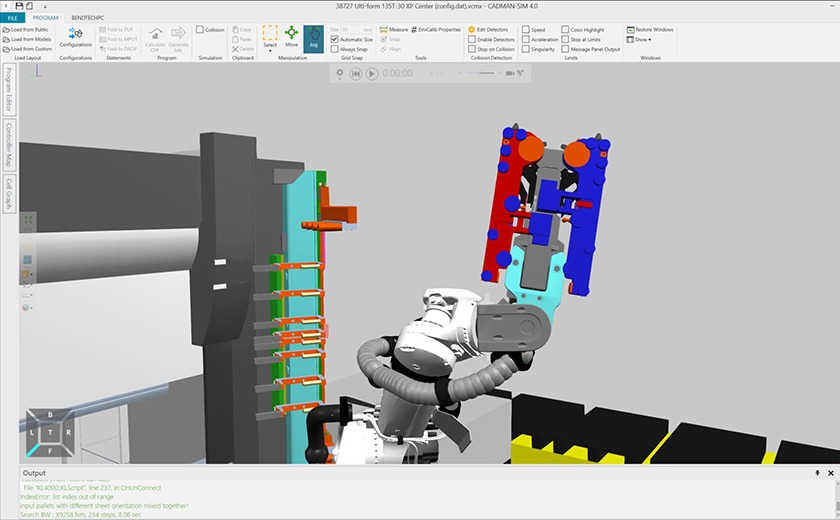

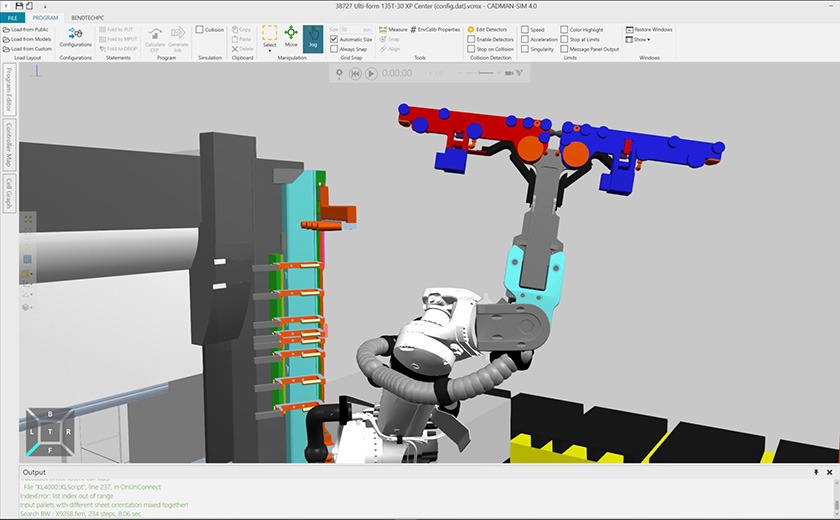

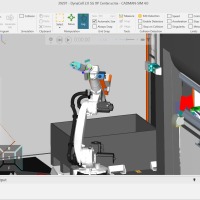

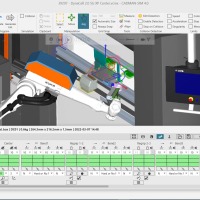

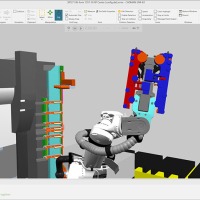

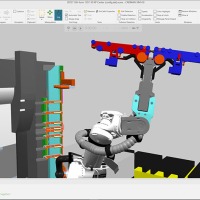

CADMAN-SIM

Robotic bending optimised

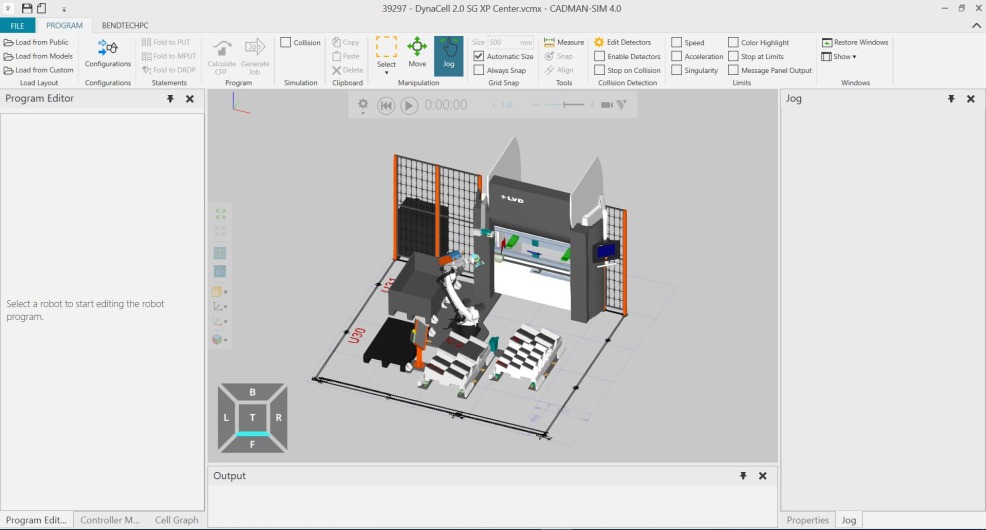

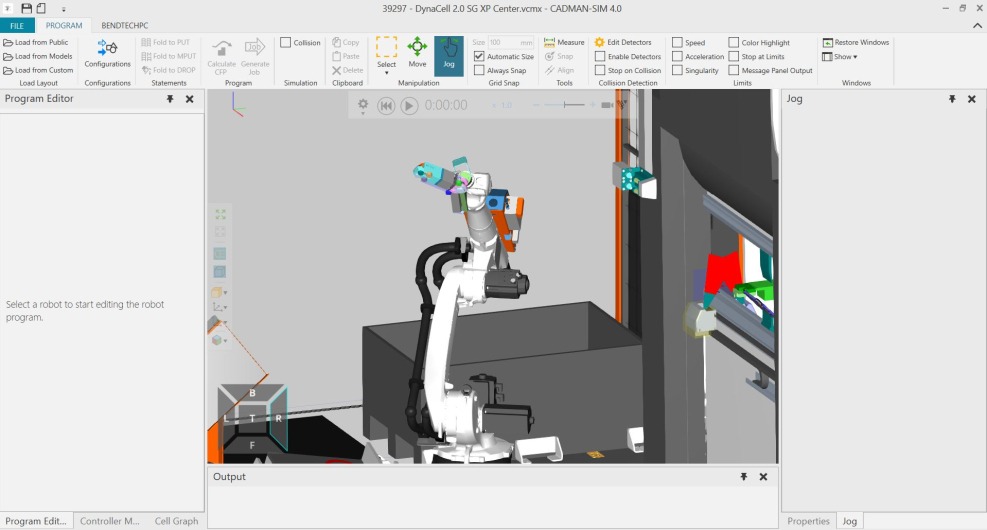

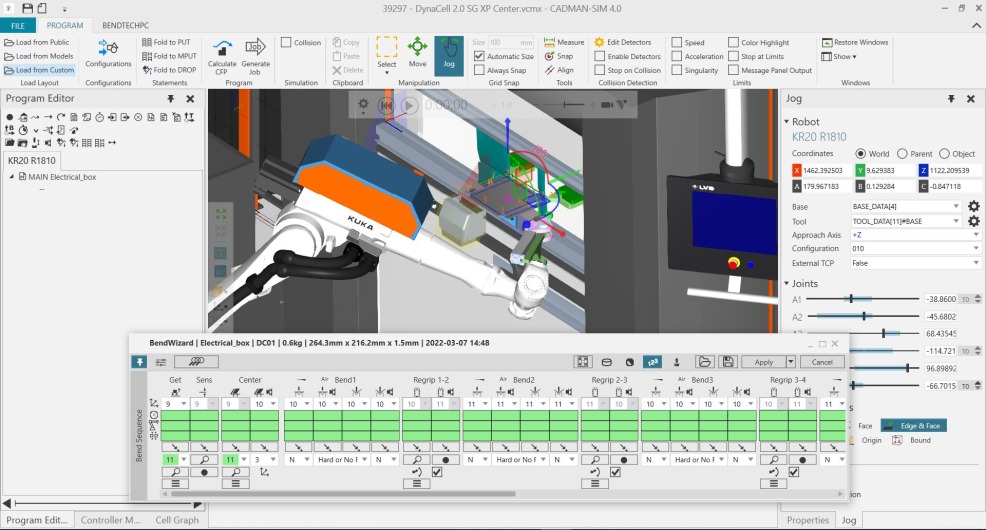

CADMAN-SIM makes automated bending easier, faster and more cost-effective. Offered as a plugin for CADMAN-B, the software elevates the efficiency of LVD’s bend CAM software to improve the efficiency of robot-based processing, providing fast collision-free robot path calculation and automatic calculation of the complete part handling for a more efficient “art to part” process.

- CADMAN-B plugin

- Makes smaller batch sizes viable for robotic bending

- Provides virtual simulation of the complete part production