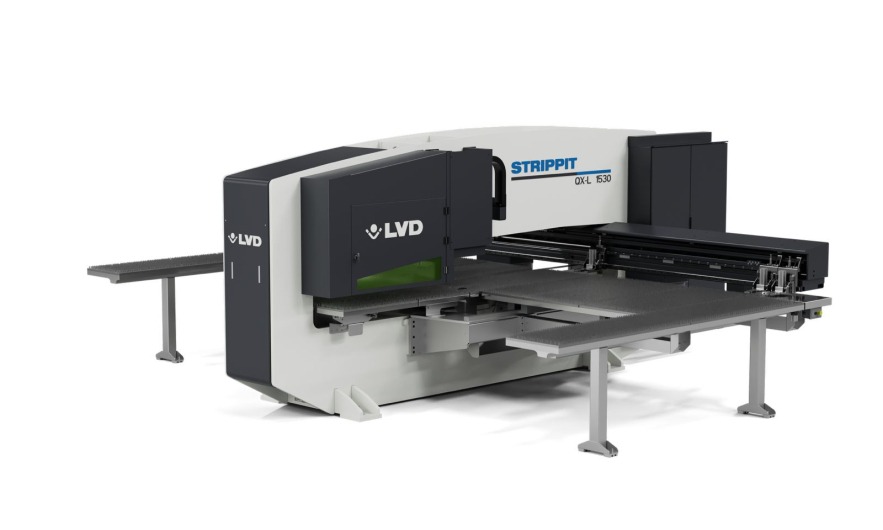

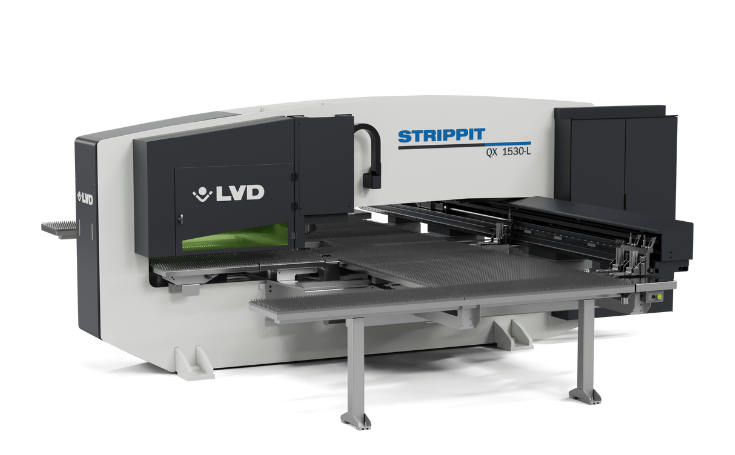

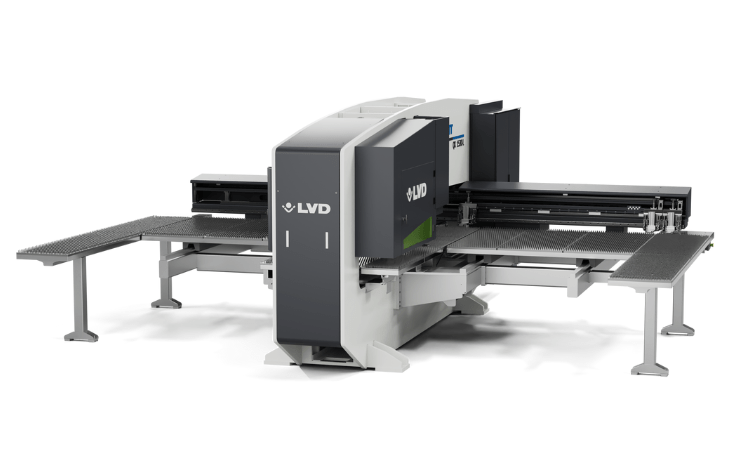

Strippit QX-L

Optimized punching, laser cutting, forming in one system

Strippit QX-L delivers the advantages of combination technology in an optimal way. A mid-range system, its features are designed for flexible punching, laser cutting and forming with the most efficiency and economy. This versatility means a faster ROI, higher throughput and lower per-part manufacturing costs.

- Single-head 20-ton punch press

- 4-kW laser source

- Sheet size format of 3050 x 1525 mm