ToolCell

Smart automation of tool changes

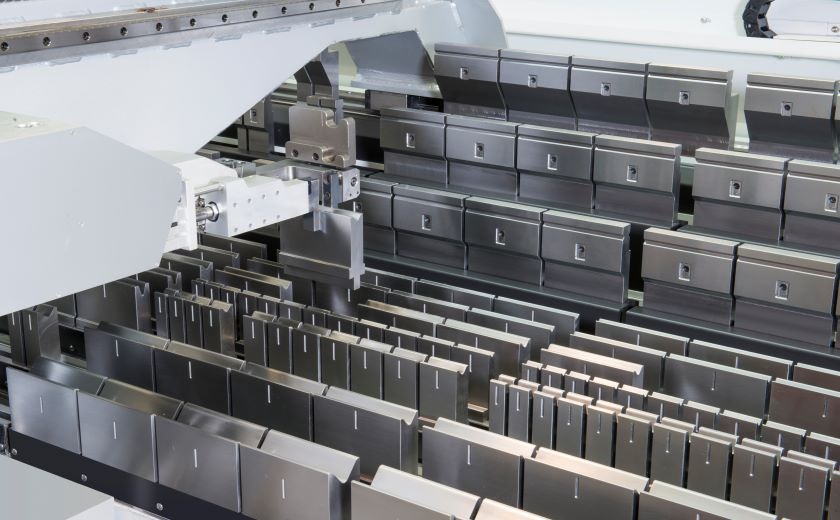

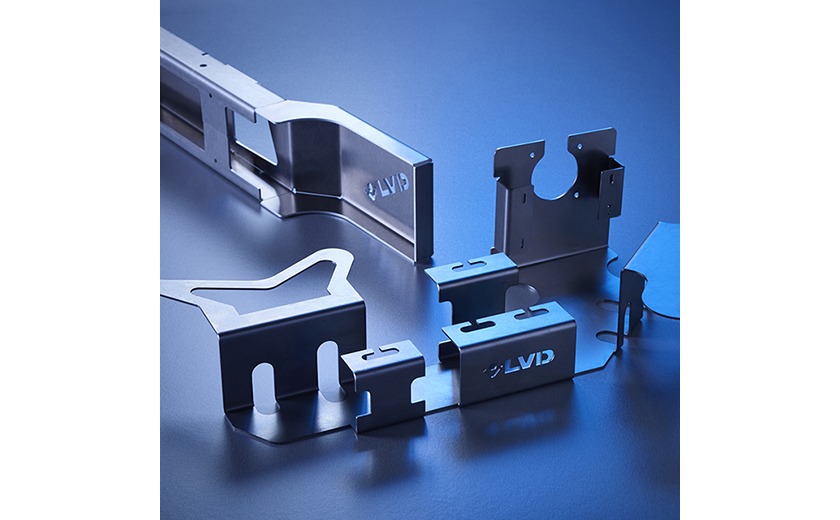

ToolCell is the ultimate bending solution for small to medium batches, a high product mix and complex parts. All tools are held within the machine and automatically changed as the job requires – minimizing tool changeover time and increasing throughput. In bending capacities from 150 to 240 tons.

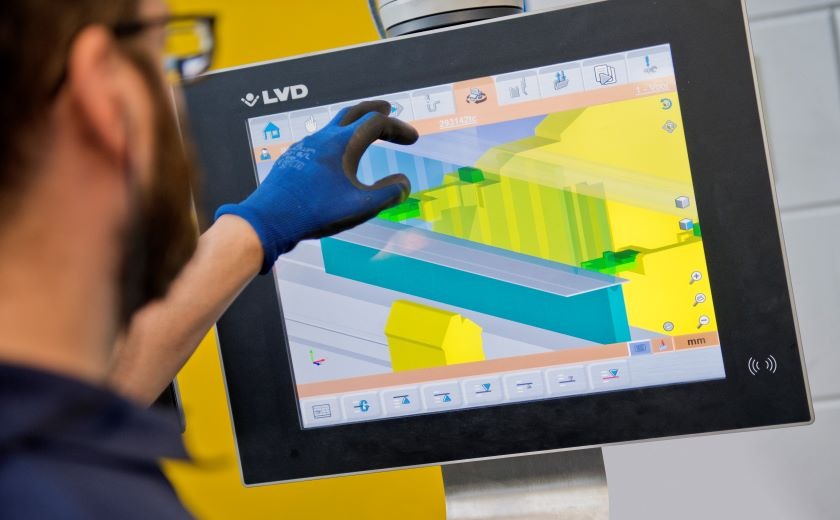

- Advanced Easy-Form® Laser adaptive bending system

- Servo-controlled hydraulic system

- Linear encoders connected to the bed for precise ram positioning

- Smart factory - Industry 4.0 compatible