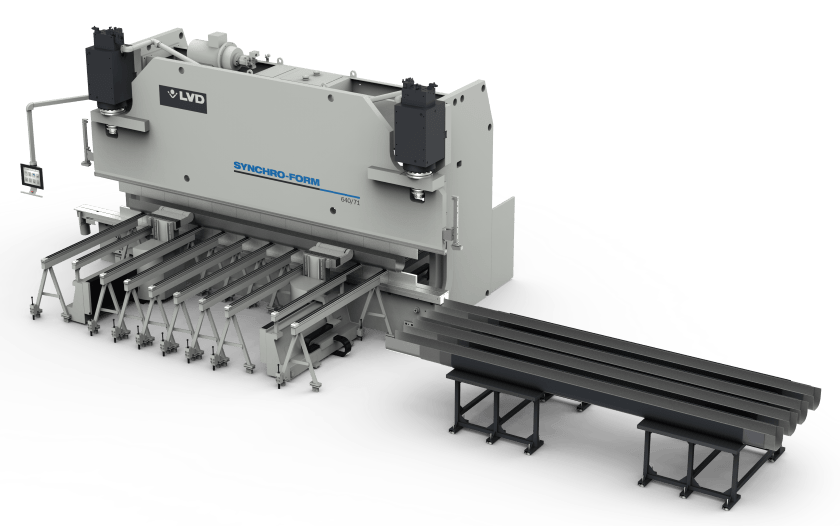

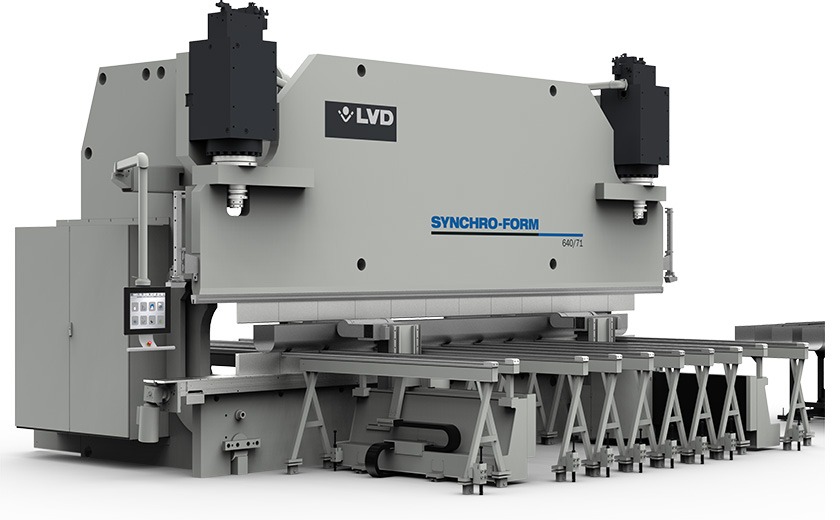

Synchro-Form

Next-evolution technology

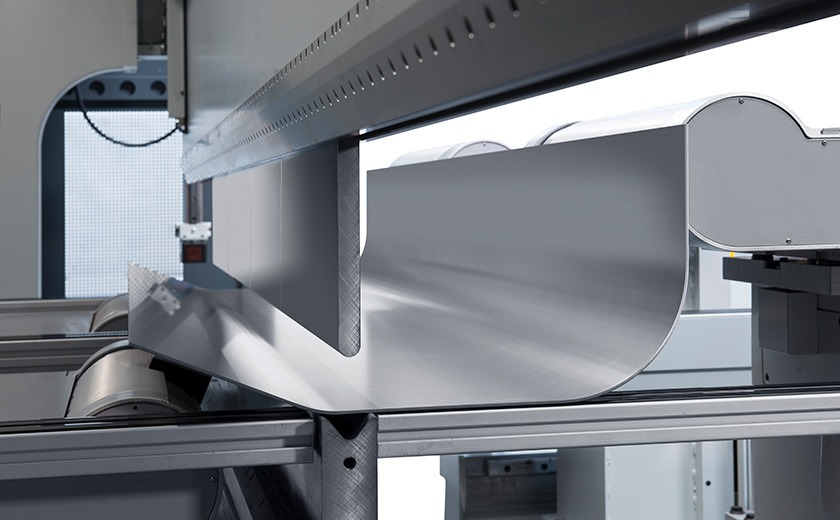

Synchro-Form press brakes eliminate manual operations, reduce setup and handling and ensure consistent bending results. In configurations up to 3000 tons by 46 feet.

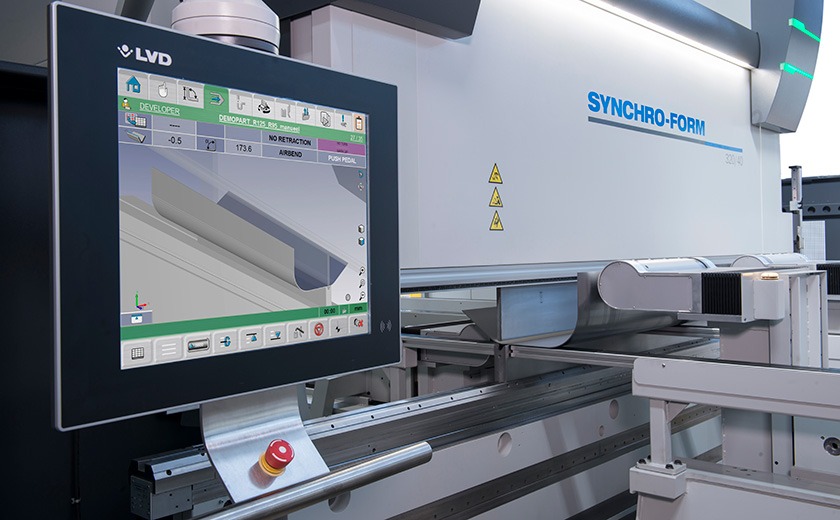

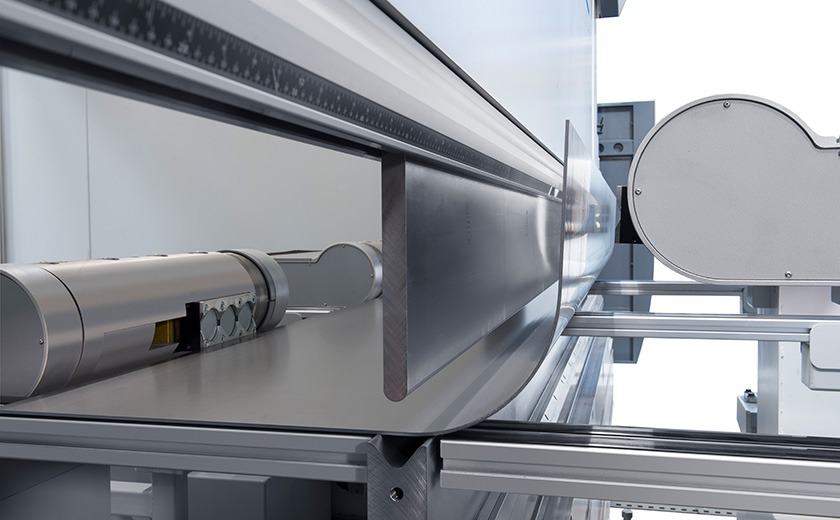

- Automatic positioning

- Automatic bending

- Measurement and compensation for accumulated error

- Smart factory - Industry 4.0 compatible